Operation - Remount Balancing (Option) MC10 HS

5 - 20

For universal shaft drive 5.5 Remount Balancing (Option)

Refer to chapter 7 Remount balancing.

Rotor data set has been created.

The machine is ready for operation and set up

on the rotor.

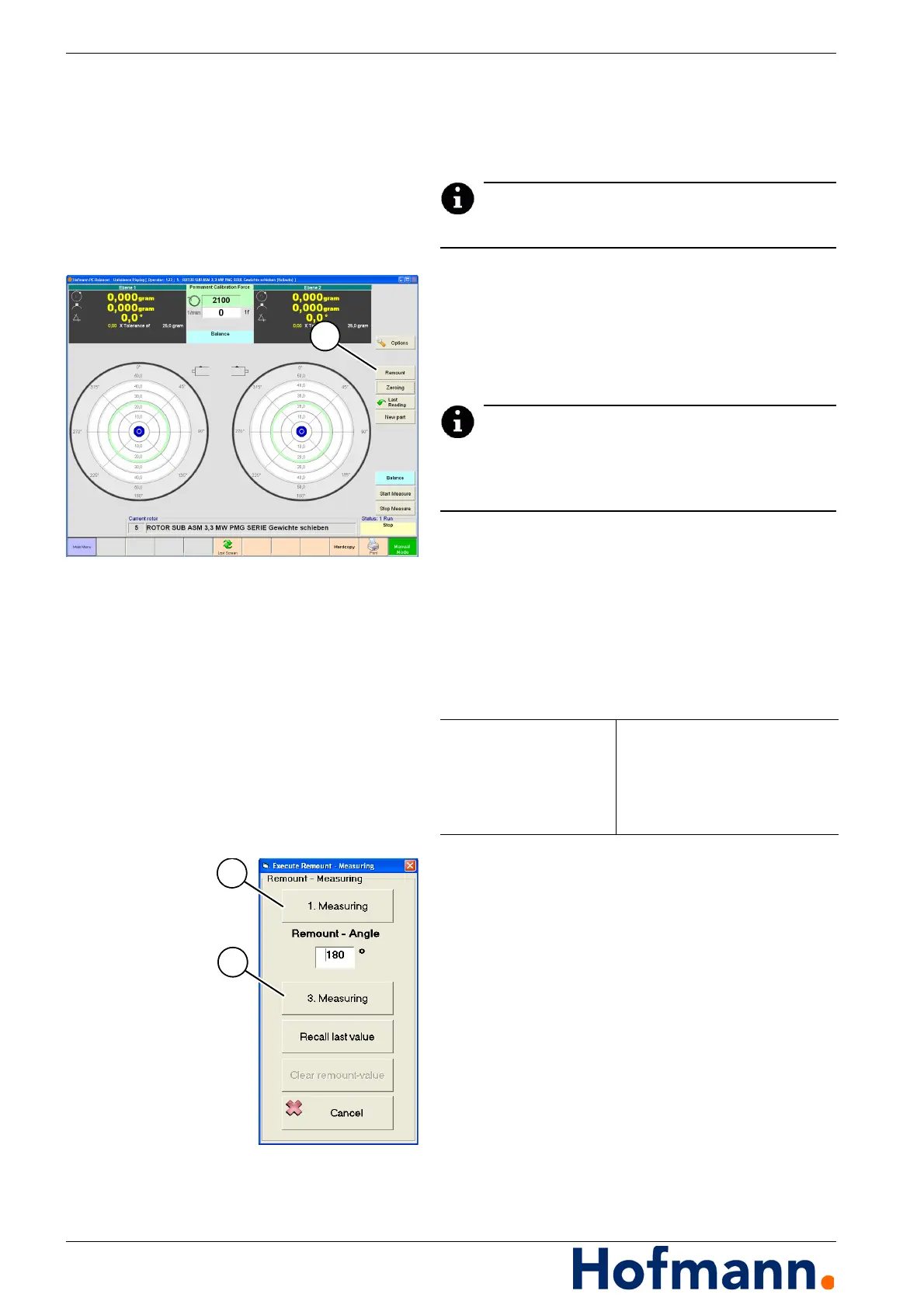

5.5.1 Remount Balancing

Remount balancing is used to distinguish between

the unbalance of auxiliary devices (e.g. universal

shafts) and the unbalance of the workpiece (rotor).

Load rotor into the machine.

Couple rotor to universal shaft.

Close protective shroud.

Carry out measuring run.

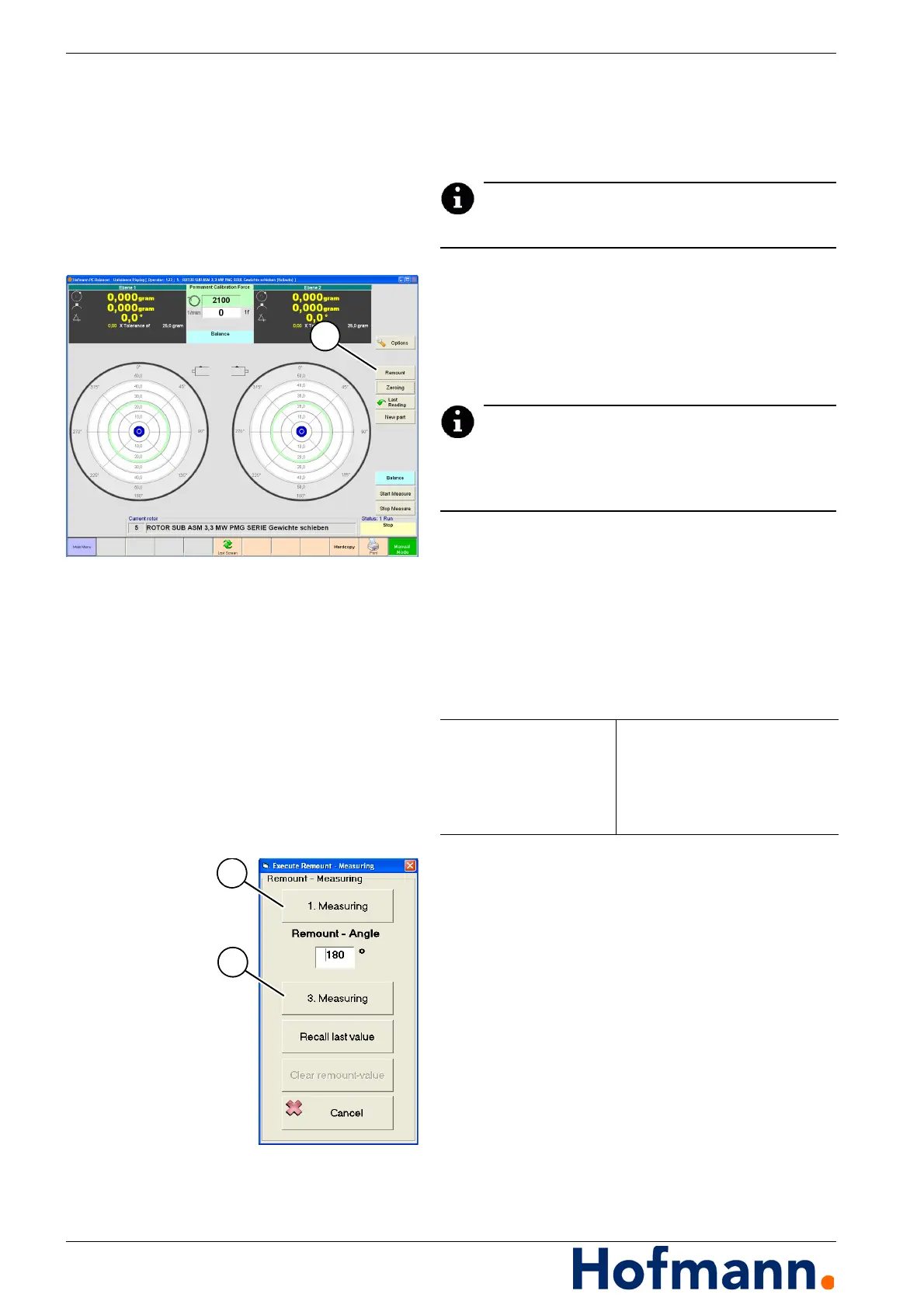

Press "Index. Bal." key (1).

Enter remount angle:

Press "1. Measuring" key (2).

Open protective shroud.

Uncouple rotor from universal shaft.

Turn rotor counter-clockwise by the value of the

entered angle with respect to the universal

shaft.

Couple rotor to universal shaft.

Close protective shroud.

Carry out measuring run.

Press "Index. Bal." key (1).

Press "2. Measuring" key (3).

Open protective shroud.

Uncouple rotor from universal shaft.

Remount angle Angle, to which the location of the

workpiece is indexed, which was

at 0°. The counting direction of

the angle scale is applicable (re-

fer to Options). The value should

be between 90° and 270°.

Loading...

Loading...