5-4

dummyheaddummyhead

IGNITION SYSTEM

SERVICE INFORMATION

GENERAL

• The ECM/PCM may be damaged if dropped. Also if the connector is disconnected when current is flowing, the excessive

voltage may damage the module. Always turn off the ignition switch before servicing.

• Use spark plug of the correct heat range. Using a spark plug with an incorrect heat range can damage the engine.

• When servicing the ignition system, always follow the steps in the troubleshooting table (page 5-5).

• Some electrical components may be damaged if terminals or connectors are connected or disconnected while the ignition switch

is turned to ON position and current is present.

• A faulty ignition system is often related to poorly connected or corroded connections. Check those connections before

proceeding.

• Make sure the battery is adequately charged. Using the starter motor with a weak battery results in a slower engine cranking

speed as well as no spark at the spark plug.

• For ECM/PCM service (page 4-67).

• Refer to following components informations:

– Ignition switch (page 22-24)

– Engine stop switch (page 22-25)

– Bank angle sensor (page 4-65)

– Sidestand switch (page 22-28)

– Neutral switch (page 22-27)

• The following color codes are used throughout this section.

SPECIFICATIONS

TORQUE VALUE

Bl = Black Bu = Blue Lg = Light green R = Red Y = Yellow

Br = Brown G = Green O = Orange W = White

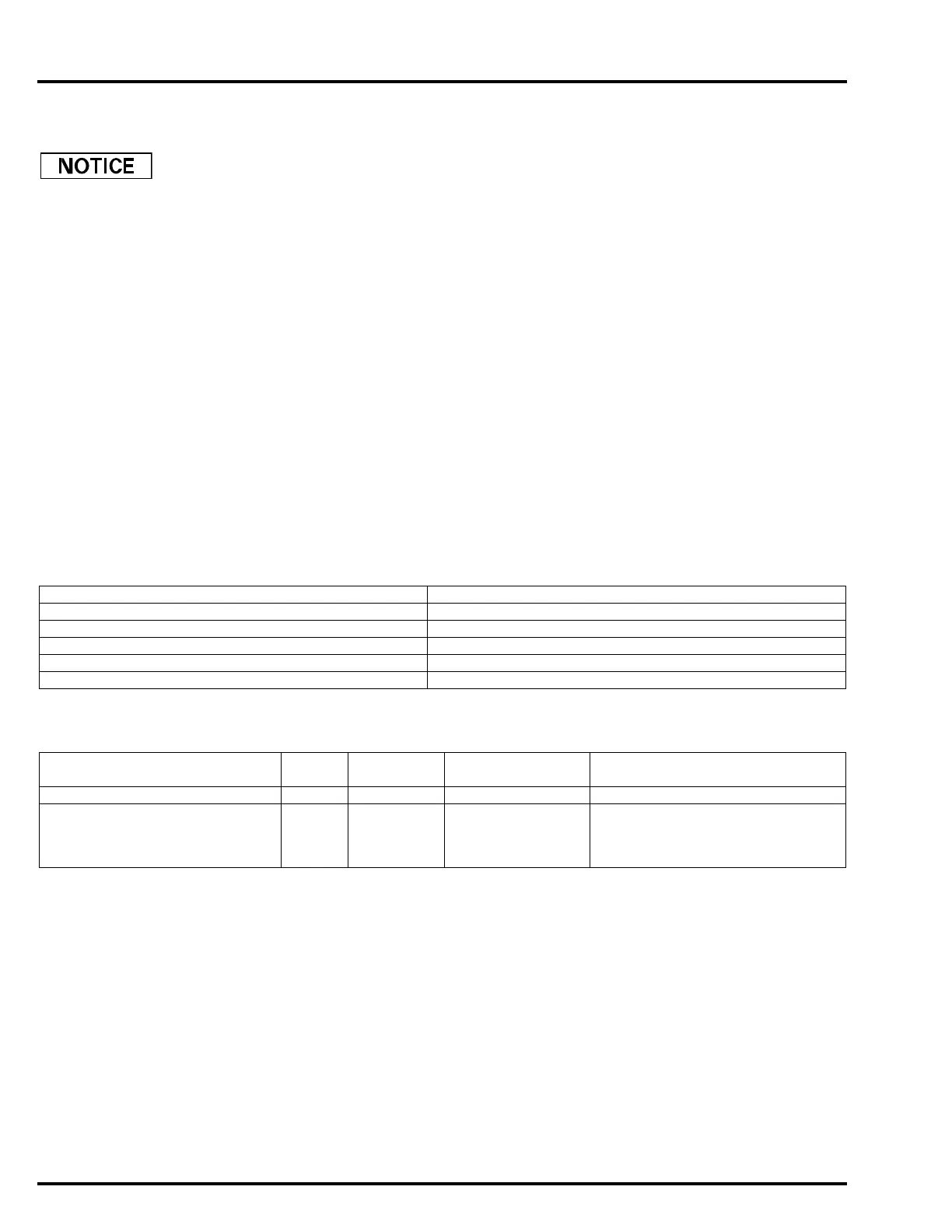

ITEM SPECIFICATIONS

Spark plug (Iridium) IFR6G-11K (NGK)

Spark plug gap 1.0 – 1.1 mm (0.039 – 0.043 in)

Ignition coil peak voltage 100 V minimum

CKP sensor peak voltage (at 20°C/68°F) 0.7 V minimum

Ignition timing ("F" mark) 12° BTDC at idle

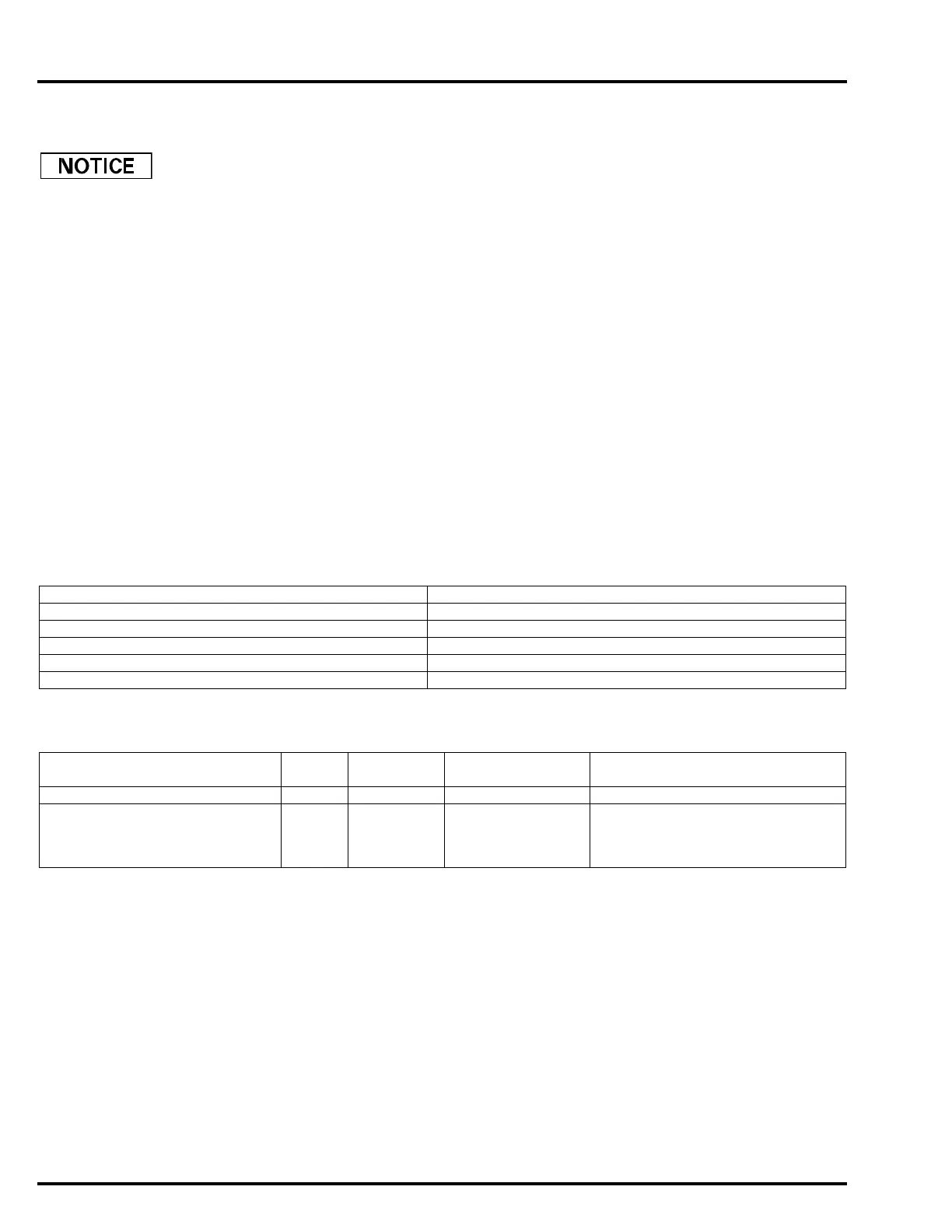

ITEM Q'TY

THREAD TORQUE

REMARKS

DIA. (mm) N·m (kgf·m, lbf·ft)

Timing hole cap 1 14 10 (1.0, 7) Apply grease to the threads.

Right crankcase cover wire clamp

bolt (NC700XD/SD)

2 6 12 (1.2, 9) Apply locking agent to the threads.

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Loading...

Loading...