Honeywell Sensing and Control 31

SC 2000, SC2001, SC3004

Rev. G, 008-0608-00

10.5.4 CALIBRATION TYPE Menu Item

This chooses the type of calibration technique to be used. There

are three methods that can be used to calibrate the transducer to

the Input Channel. Each has advantages and disadvantages as

described in the table below

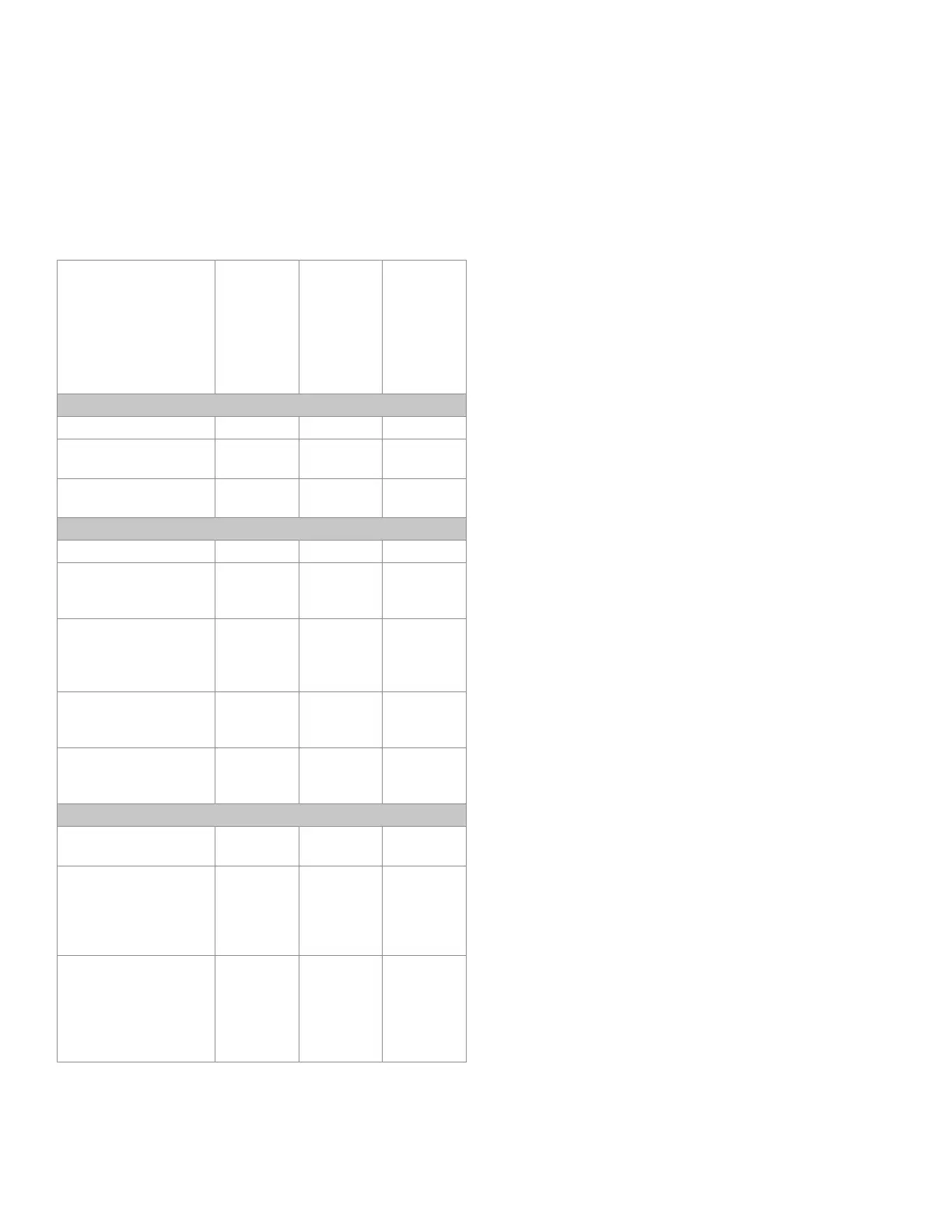

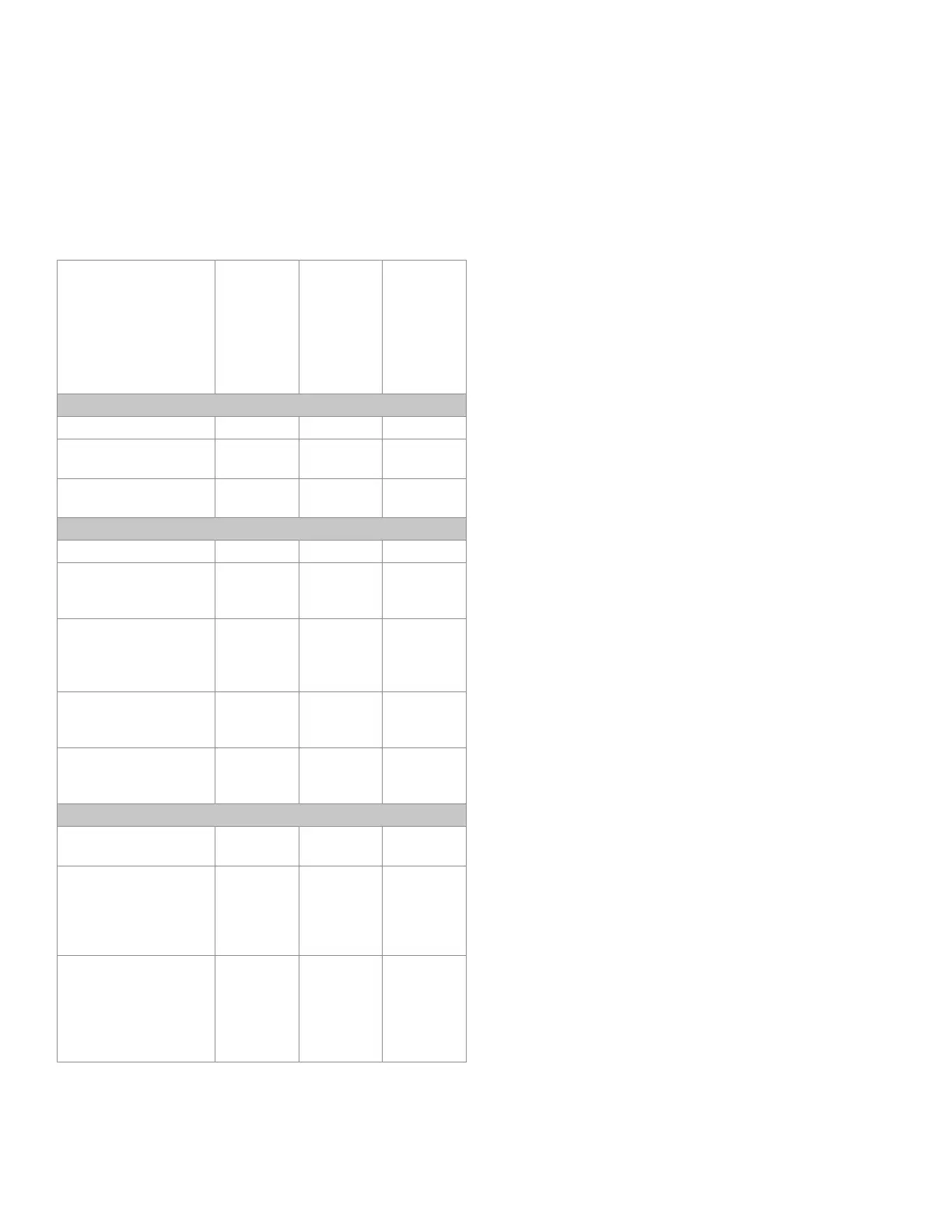

Table 10-: Comparison of Calibration Types

Shunt Calibration

mV/V Calibration

2-, 3-, or 5-point

Known Load Cali-

bration

RECOMMENDED...

...for most applications no yes no

...when frequently

swapping transducers

yes yes no

...when best possible

accuracy required

no no yes

PROs and CONs

Relative accuracy good better best

Requires actual,

calibrated loads to be

applied

no no yes

Automatically cali-

brates with Signature

Calibration transduc-

ers

yes yes no

Max. distance of trans-

ducer from instrument

w/out sense wires

15 ft [5 m] 50 ft

[15 m]

300 ft

[100 m]

Max. distance of trans-

ducer from instrument

with sense wires

15 ft [5 m] 100 ft

[30 m]

300 ft

[100 m]

CALIBRATION TECHNIQUE

Zero-scale point from... applied

load

applied

load

applied

load

Full-scale point from... transducer

output

when shunt

resistor

applied

internal

reference

applied

load

Linearity correction

from...

data

stored in

Signature

Module (if

available)

data

stored in

Signature

Module (if

available)

2-point:

none;

3- or

5-point:

applied

load

It is important to know your application in order to select the

appropriate calibration type. mV/V (“millivolt-per-volt”) Calibra-

tion is recommended for most applications because it doesn’t

require known loads and it allows easy swapping of transducers

equipped with Signature Calibration. When the best possible ac-

curacy is required, Known-Load Calibration is recommended.

The choices for this menu item are:

• “TYPE= SHUNT CAL” means Shunt Calibration. First, you are

prompted to apply the load entered in the “ZERO SCALE VAL-

UE” register. Next, the instrument inserts a known, precision

resistor into the transducer circuit, which causes a predict-

able apparent signal. The instrument then takes a reading

and adjusts itself using the “SHUNT CAL VALUE” register.

• “TYPE= MV/V CAL” means Millivolt-per-Volt Calibration. First,

you are prompted to apply the load entered in the “ZERO

SCALE VALUE” register. Next, the instrument takes a reading

from an accurate, internal mV/V reference. The instrument

then uses the “FULL SCALE MV/V” and “FULL SCALE VALUE” val-

ues in mathematical calculations to scale its tracking values.

• “TYPE= 2 POINT CAL” means 2-Point Known Load Calibra-

tion. You are prompted to apply the loads to the transducer

that were entered in the “KNOWN POINT 1/2” and “KNOWN POINT

2/2” registers. This technique assumes that the transducer is

linear, so the usual loads used are zero scale and full scale.

• “TYPE= 3 POINT CAL” means 3-Point Known Load Calibration.

You are prompted to apply the loads to the transducer that

were entered in the “KNOWN POINT 1/3” and “KNOWN POINT 2/3”

and “KNOWN POINT 3/3” registers. This technique can be used

to compensate for the non-linearity in the transducer. The

usual loads used are zero scale, half scale and full scale, but

you are not restricted to these loads.

• “TYPE= 5 POINT CAL” means 5-Point Known Load Calibration.

You are prompted to apply the loads to the transducer that

were entered in the “KNOWN POINT 1/5”, “KNOWN POINT 2/5”,

“KNOWN POINT 3/5”, “KNOWN POINT 4/5” and “KNOWN POINT

5/5” registers. This technique can be used to compensate

for the non-linearity in the transducer. The usual loads used

are zero scale, one-quarter scale, half scale, three-quarters

scale and full scale, but you are not restricted to these loads.

The selection of the calibration type affects what menu items ap-

pear in the CALIBRATION DATA sub-menu.

Loading...

Loading...