MEP S.p.A.

10--6 Use and maintenance manual DM 8

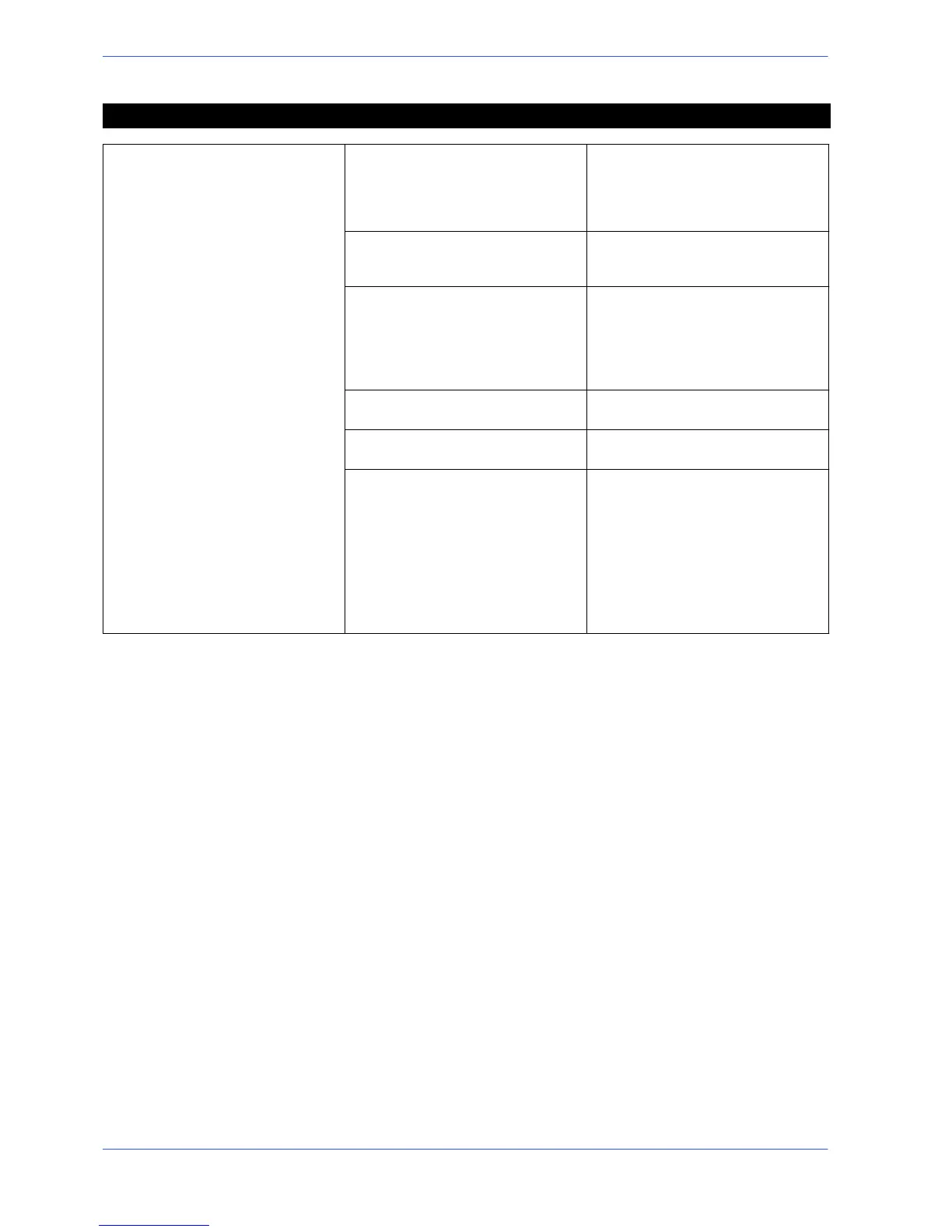

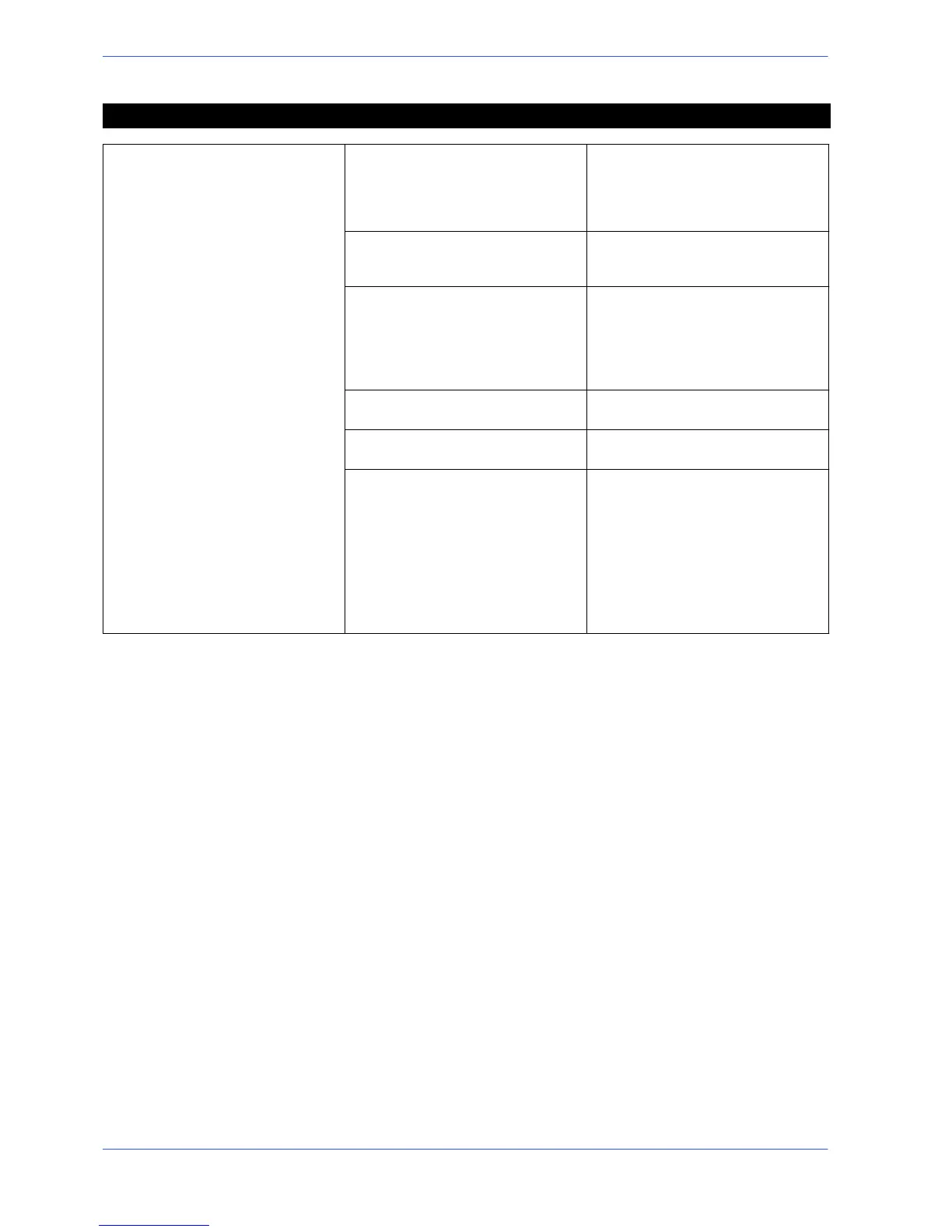

PROBLEM PROBABLE CAUSE SOLUTION

Blade broken (continued)

' Free blade guide head .The head is too far away from the

workpiece: move the head closer,

leaving free only that part of the

blade actually needed to make the

cut

' Teeth in contact with the material be-

fore starting the cut

.Always check the position of the

blade before starting a new job, es-

pecially for the semi--automatic cycle

' Blade guide .If worn, the inserts can score the

blade, weakening it even to breaking

point. If the inserts are too far apart,

the blade will whip, striking both the

inserts and the material. Replace or

adjust

' Insufficient coolant .Check coolant fluid level; clean

pipes and jets

' Incorrect fluid concentration .Check and use the correct con-

centration

' The blade stops in the cut .Cutting pressure too high: check

pressure and reset to rated pressure

.Head downstroke speed too fast: re-

duce

.Head downstroke speed too slow:

increase

.The blade slips on the flywheels: in-

correct or low blade tension; readjust

or increase

Loading...

Loading...