OperatiOn

4-16 powermax

65/85

Service Manual

Pierce a workpiece

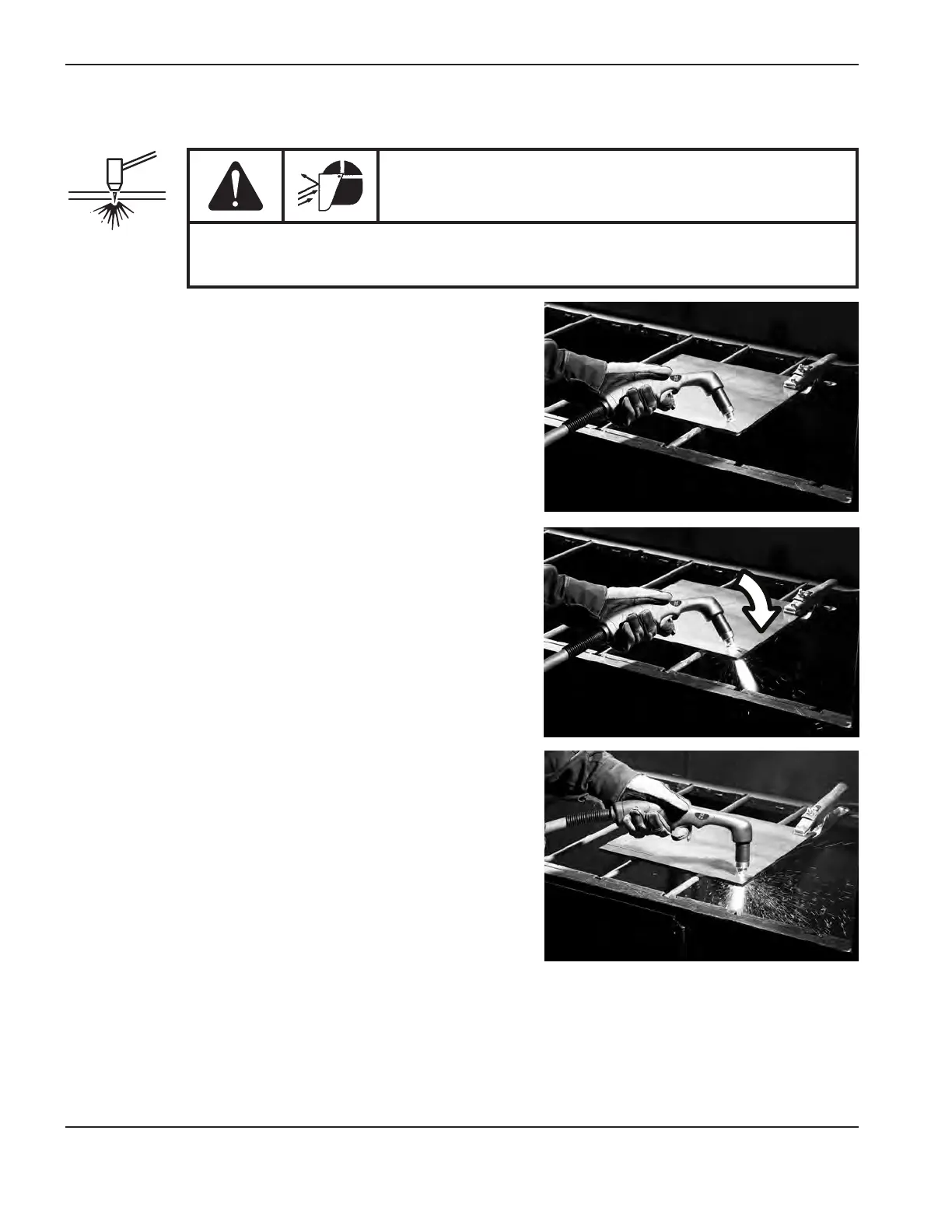

1. With the work clamp attached to the workpiece, hold the torch

at an approximate 30° angle to the workpiece with the torch

tip within 1/16 inch (1.5 mm) of the workpiece before firing the

torch.

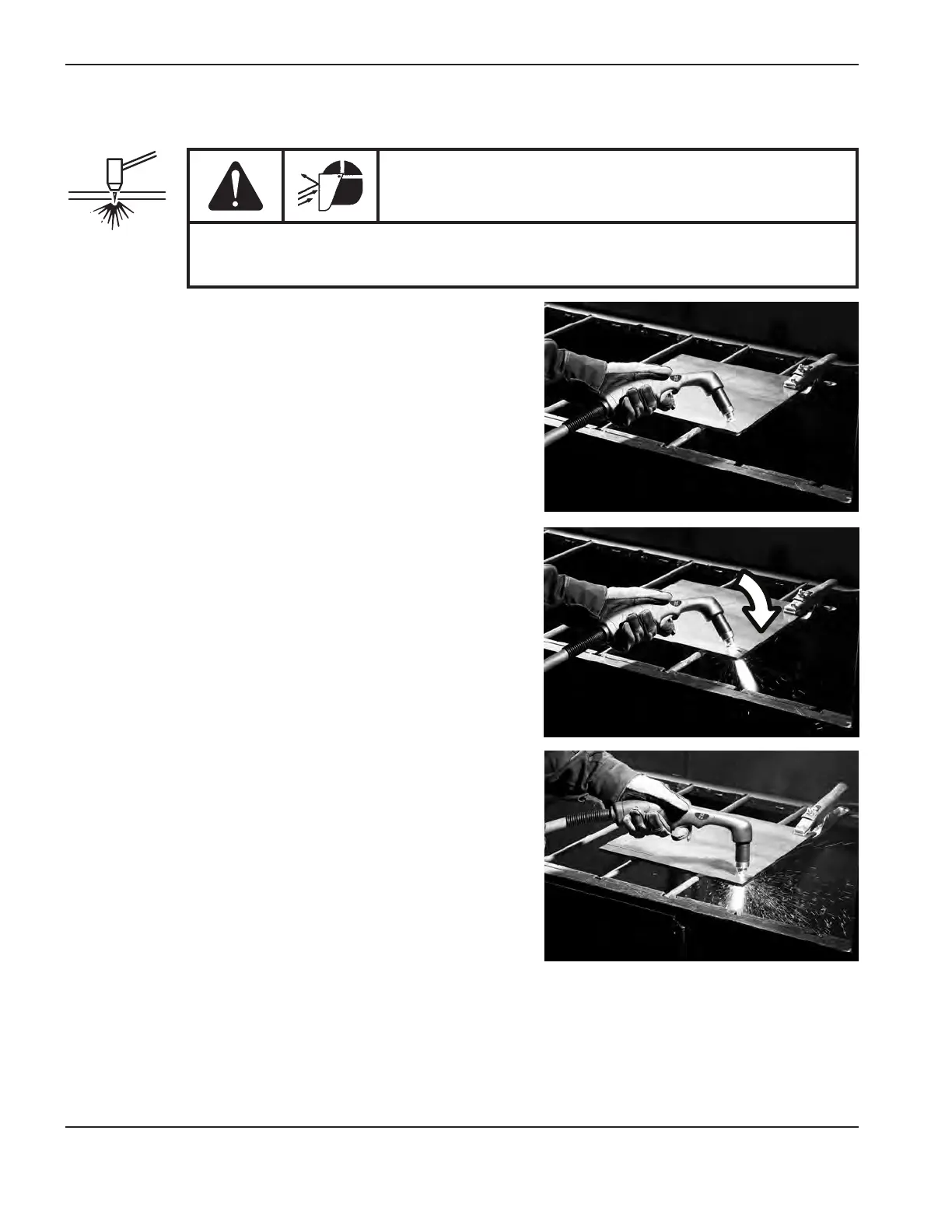

2. Fire the torch while still at an angle to the workpiece. Slowly

rotate the torch to a perpendicular (90°) position.

3. Hold the torch in place while continuing to press the trigger.

When sparks exit below the workpiece, the arc has pierced the

material.

4. When the pierce is complete, dragthe nozzle lightly along the

workpiece to proceed with the cut.

WARNING

SPARKSANDHOTMETALCANINJUREEYESANDBURNSKIN.When firing the

torch at an angle, sparks and hot metal will spray out from the nozzle. Point the

torch away from yourself and others.

Loading...

Loading...