TroubleshooTing and sysTem TesTs

5-44 powermax

65/85

Service Manual

For operational fault codes 0-40-0 and 0-40-1 or power board faults 3-11-0 and 3-11-1 (CSA only)

1. Remove PFC temperature sensor connector (J16) from power board.

2. Check the resistance between pins 1 and 2 on the plug. Resistance should be about 5.5kΩ.

3. If the resistance is incorrect, replace the PFC IGBT, gate drive wires, and PFC temperature sensor wire.

4. If the value is correct, measure resistance between pins 1 and 2 on the power board with the temperature sensor

disconnected. The resistance should be about 4.7kΩ.

5. If the value is correct, replace DSP board.

6. If the value is incorrect, replace power board.

BLK

BLK

J13

J16J17J18J19

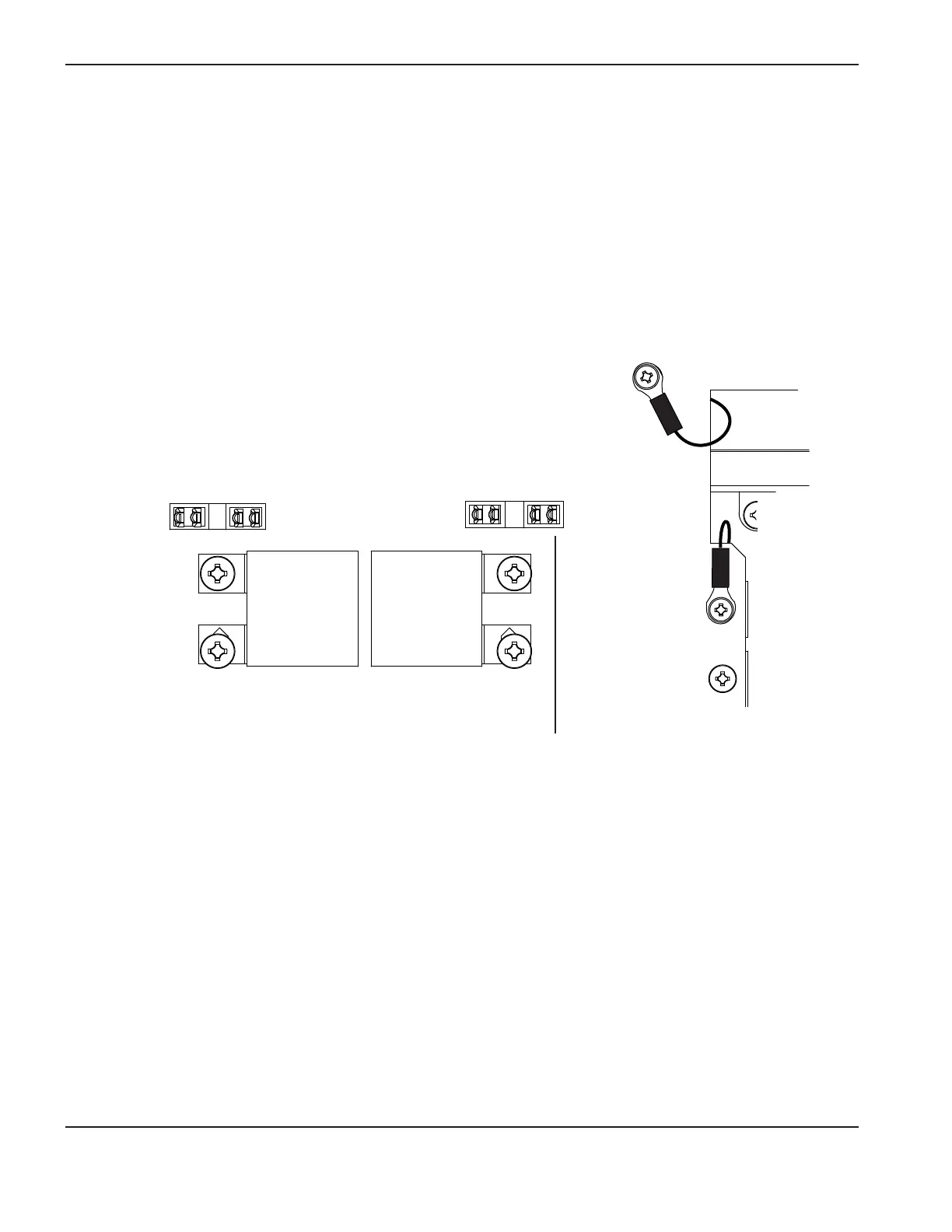

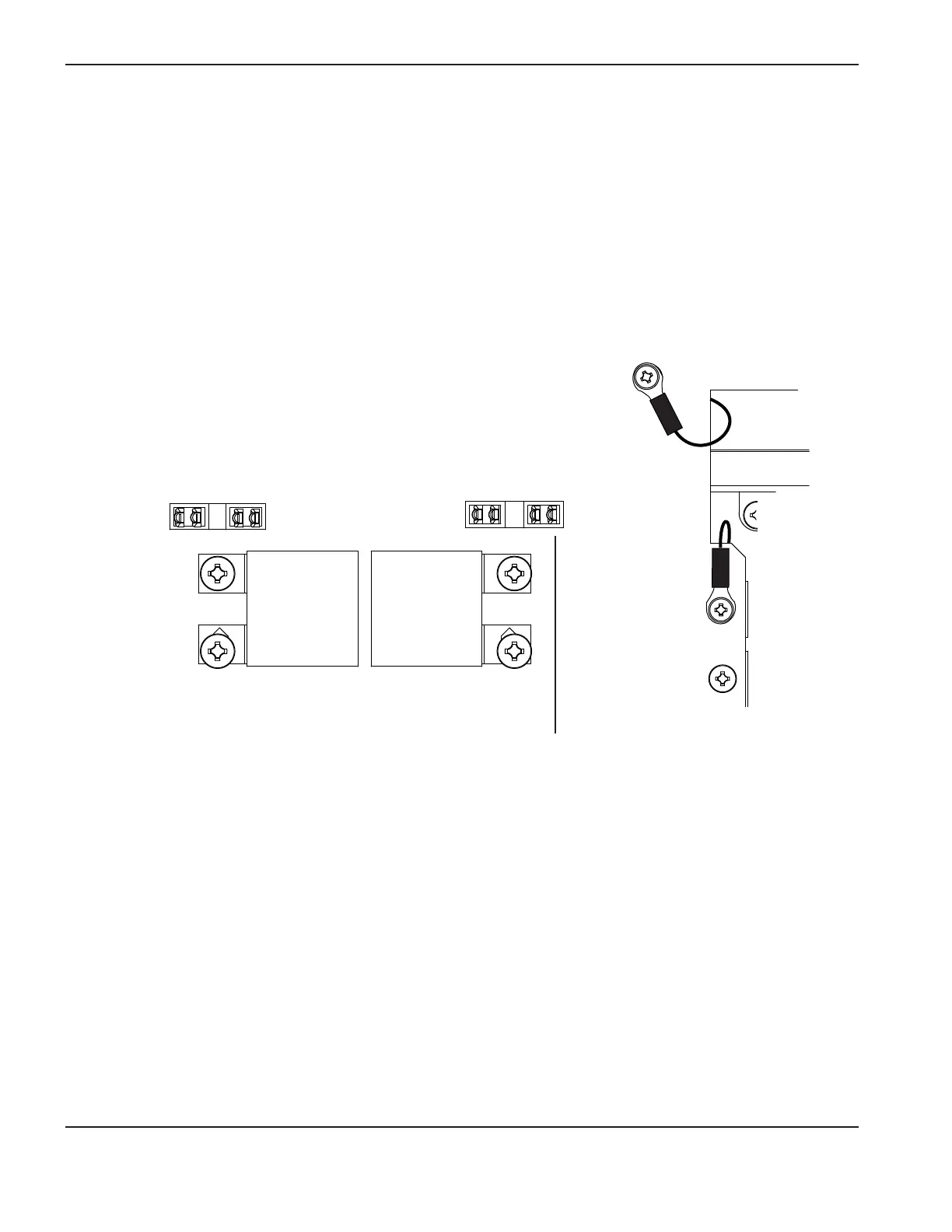

PFC temperature sensor connection

Loading...

Loading...