42

Part 1 Installation

(2) Calculation example

Obtain the power-source capacities and heat outputs when a controller of the following specifications is

used.

Actuator for axis 1: 200 W Actuator for axis 2: 200 W Actuator for axis 3: 100 W with brake

Actuator for axis 4: 60 W Standard controller with standard DIO

Options: DeviceNet, teaching pendant (IAI’s standard type)

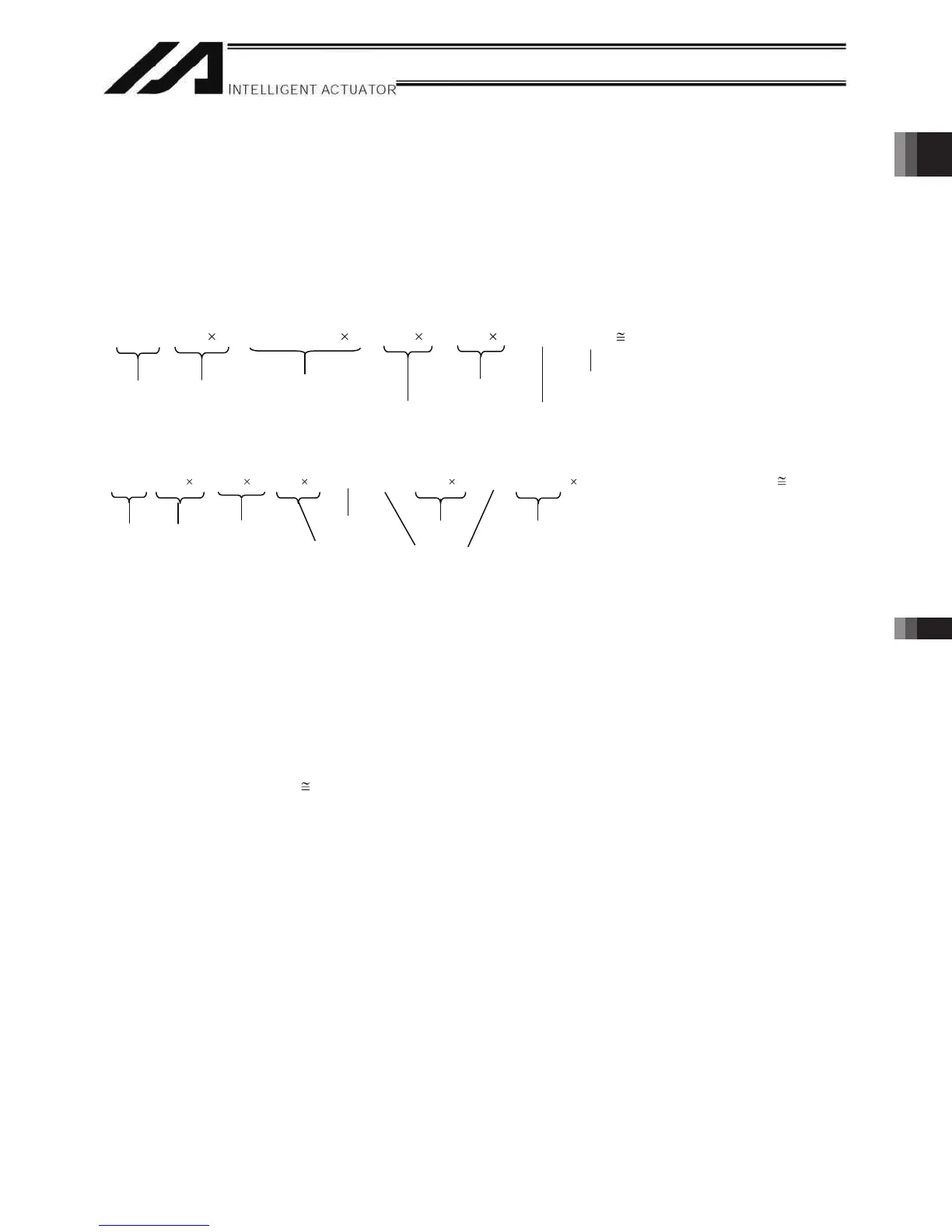

[1] Control power-supply capacity

{31.14 + 6.26 2 + (2.38 + 3.57) 4 + 4.57 4 + 5.95 1 + 2.38 + 3.57} 97.9 [VA]

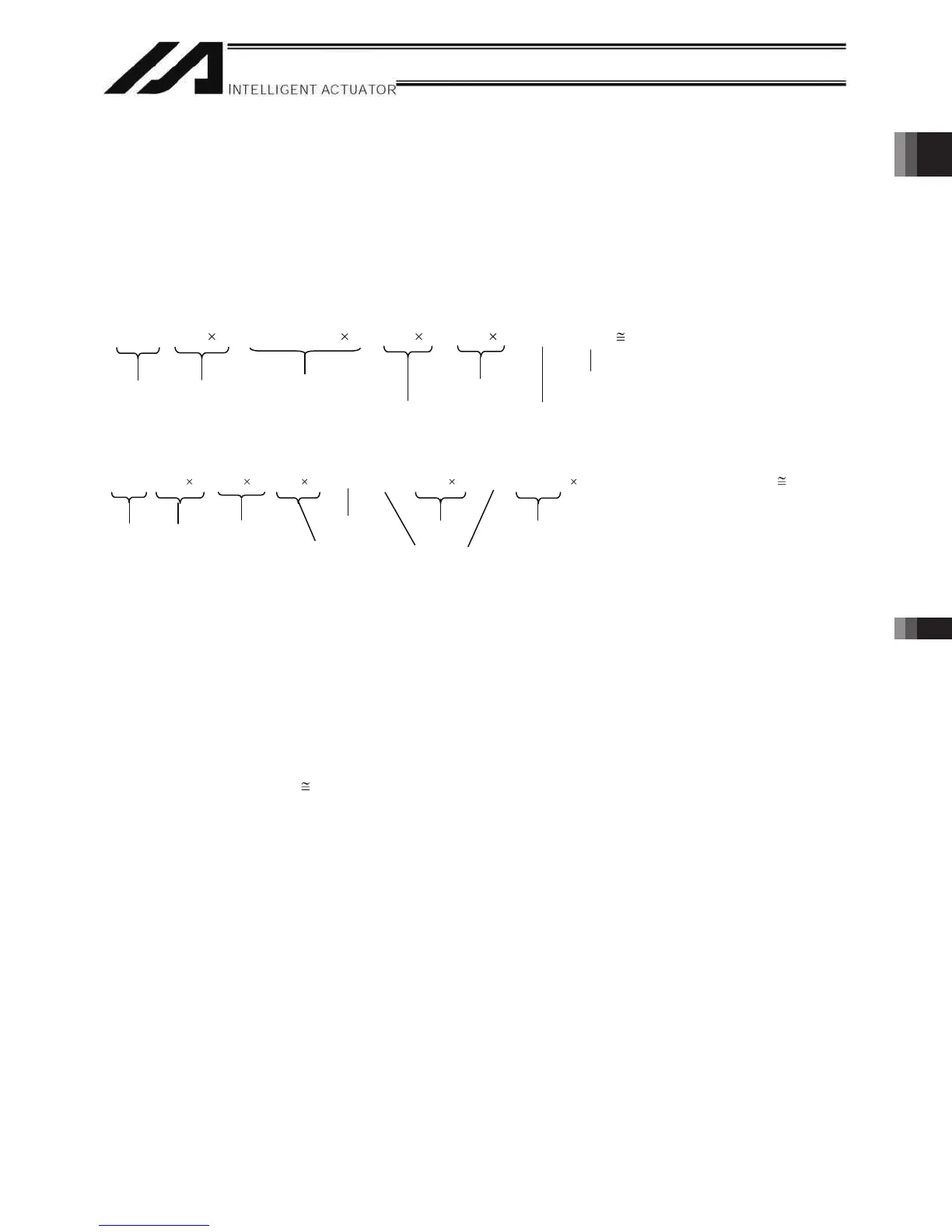

[2] Heat output from control system

{(31.14 + 6.26 2 + 2.38 4 + 4.57 4 + 5.95 + 2.38) + (14.52 1 + 1.71 + 5.95 x 1)} 0.7 (Efficiency) x 0.6 (Power factor) 43 [W]

[3] I/O power-source capacity (24 VDC)

14.52 x 1 = 14.52 [VA]

[4] Brake power-source capacity (24 VDC)

(5.95 + 13.81) x 1 = 19.76 [VA]

[5] Motor power-source capacity

421 + 421 + 234 + 138 = 1214 [VA]

[6] Heat output from motor power supply

9.12 + 9.12 + 6.12 + 3.39 27.8 [W]

[7] Power-source capacity = [1] Control power-source capacity + [5] Motor power-source capacity

= 97.9 + 1214 = 1311.9 [VA]

[8] Heat output = [2] Heat output from control system + [6] Heat output from motor power supply

= 43 + 27.8 = 70.8 [W]

DIO

DeviceNet

DIO

DIO

DeviceNet

Encoders

Drivers

Base part

Fan units

Teaching pendant

Encoders

Drivers

Base part

Fan units

Brake

Loading...

Loading...