Part 1 Installation

3. Power-Source Capacity and Heat Output

The power consumption and heat output of the XSEL controller will vary depending on the number of connected

axes and I/O configuration. This section explains how to estimate the power-source capacity and heat output of

your XSEL controller.

The XSEL controller requires the following power supplies:

A. Control power

Power to the logic control part of the controller. Single-phase 200 VAC must be supplied.

B. Motor power

Power for driving the actuator. Three-phase (single-phase) 200 VAC must be supplied.

* A single-phase power source is required only for controllers of single-phase specification.

C. I/O power

If a DIO card is installed in an I/O slot, 24 VDC must be supplied.

D. Supplemental power input (Power source to release brake and drive actuator)

It is necessary to supply 24V DC when connecting an actuator equipped with a brake or that recommended by IAI.

Recommended actuator (as of January, 2014): CT4 Pick & Rotary Actuator

(1) Power-source capacity and heat output

Rated power-source capacity [VA] = Motor drive power [VA]

*1

+ Control power-source capacity [VA]

*2

Heat output [W] = Total sum of output losses [W]

*3

+ (Heat output from control power supply [VA]

*4

x 0.7

(Efficiency) x 0.6 (Power factor))

*1 Select an appropriate motor drive power [VA] from Table 1. Note that during acceleration/deceleration, the

motor drive power increases by up to three times (or by up to twice if the motor wattage is 600 W or 700 W).

*2 Calculate the control power-source capacity [VA] by selecting the installed parts and then adding up the

power x quantity products of all installed parts according to the “Control power supply (Internal consumption,

External consumption)” fields of Table 2.

*3 Calculate the total sum of output losses [W] by selecting from Table 1 the output losses for all actuators to

be connected.

*4 Calculate the heat output from control power supply [VA] by selecting the installed parts and then adding up

the power x quantity products of all installed parts according to the “Control power supply (Internal

consumption)” and “External power supply (Internal consumption)” fields of Table 2.

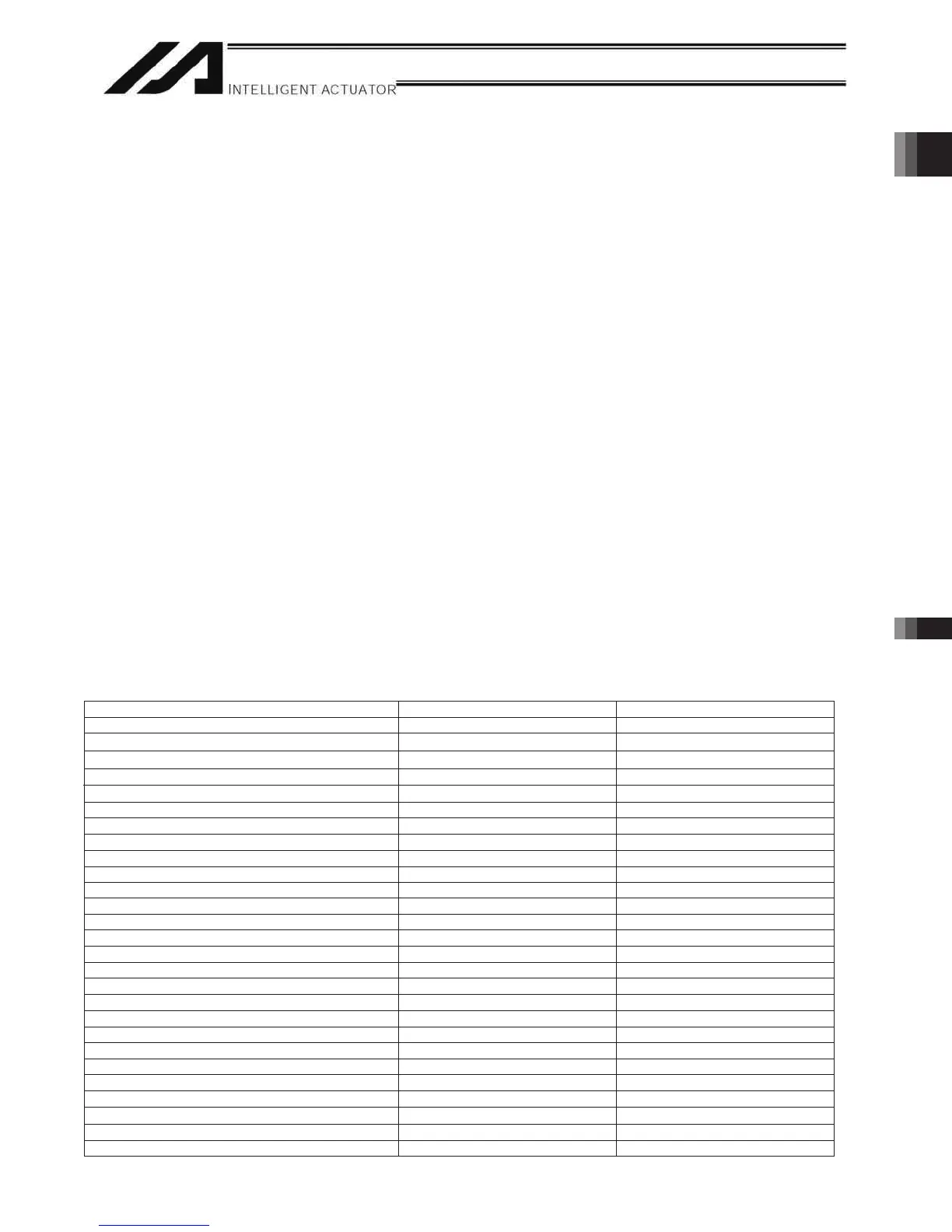

Table 1. Motor Drive Powers and Output Losses (P/Q/PCT/QCT Types)

Actuator motor capacity [W] Motor drive power [VA] Output loss [W]

85.16202

30D (other than RS)

70.264

30R (RS)

39.3831

39.383

197 3.6

7.5

10

60(RCS3-CTZ5C-□-60)

1230 18.0

400(RCS3-CT8C-□-400)

6

21.6432001

03.8823051

21.9124002

67.91697004

02.724611006

77.921251057

100 (LSA-S6S) 101 3.74

100 (LSA-S8S) 159 4.07

100 (LSA-S8H) 216 3.84

100S (LSA-N10S) 284 4.48

200 (LSA-S10S) 343 5.35

200 (LSA- H8S,L15S) 189 5.38

200 (LSA-H8H) 379 5.38

200S (LSA-S10H) 417 5.01

200S (LSA-N15S) 486 4.37

200S (LSA-N15H) 773 6.42

300S (LSA-N19S) 662 11.58

400 (LSA-W21S) 920 16.68

1000 (LSA-W21H) 1843 37.77

RS: Rotational axis / LSA: Linear actuator

DD Motor (LH18S, H18S)

DD Motor (LT18S, T18S)

1462

503

20.8

Loading...

Loading...