57

Part 1 Installation Chapter 6 Safety Circuit

Part 1 Installation

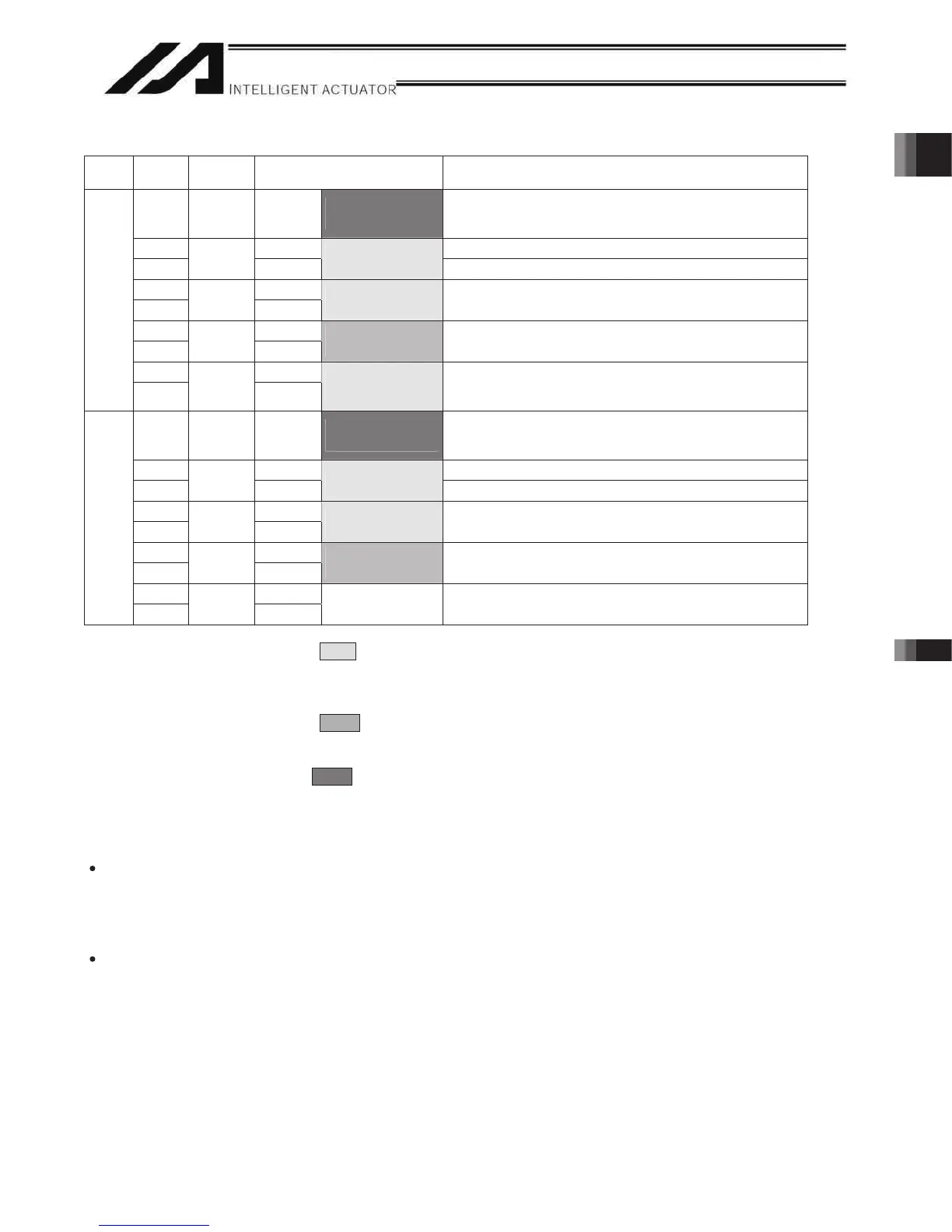

Terminal Assignments

Pin No.

Signal

name

sliateDweivrevO

9DET IN

To fused-contact

detection circuit

External contact error input (paired with No. 18)

Connected to the fused-contact detection contacts of the

safety circuit.

8 IN Emergency-stop detection input

7

EMGin

+24V

To EMG status of

safety circuit

24-V power output for emergency-stop detection input

6 line+

5

EMG1

line-

To EMG switch

circuit 1

Emergency-stop switch 1

Wire circuit 1 connected to EMG of the TP

4 line+

3

EMG2

line-

To EMG switch

circuit 2

Emergency-stop switch 2

Wire circuit 2 connected to EMG of the TP

2 Out+

Left

1

SDN

Out-

To interlock of

safety circuit

External relay drive source cutoff contact output

Signal for requesting the controller to cutoff the drive

source

18 DET +24V

To fused-contact

detection circuit

24-V power output for external contact error input

Connected to the fused-contact detection contacts of the

safety circuit.

17 IN Enable detection input

16

ENBin

+24V

To EMB status of

safety circuit

24-V power output for enable detection input

15 line+

14

ENB1

line-

To enable circuit

1

Enable switch 1 (safety gate, etc.)

Wire circuit 1 connected to ENB of the TP

13 line+

12

ENB2

line-

To enable circuit

2

Enable switch 2

Wire circuit 2 connected to ENB of the TP

11 Out+

Right

10

RDY

Out-

May be used if

necessary

Ready signal contact outputs (dry contacts) (for inductive

load of up to 200 mA)

In the table, the signals shown in fields (EMGin, EMG1, SDN, ENBin, ENB1) must always be connected

regardless of the required safety category. If these signals are connected wrongly or not connected, the safety

functions will be compromised.

In the table, the signals shown in fields (EMG2, ENB2) must be connected to meet safety category 3 or

above. They are designed to provide redundant safety circuits.

In the table, the signal shown in fields (DET) provides an input for detecting malfunction of the safety

circuit (mainly fused relay contacts). Be sure to use this signal if you want the XSEL controller to detect fused

contacts. If the safety circuit is configured as a closed system to manage fused contacts and other problems

independently, safety category 4 can be met without connecting this signal to the controller.

DET

DET (IN) and DET (+24V) are dry contact input terminals consisting of a photocoupler. By inputting fused-

contact detection signals from the drive-source cutoff safety circuit, the controller will be able to detect

problems in the external safety circuit.

SDN

SDN (OUT+) and SDN (OUT-) are output contacts that remain open while the controller is prohibiting the

motor power supply from the external power source. This condition will occur immediately after the controller

power is turned on, when an error occurs in the equipment, or when a drive-source cutoff cancellation

command is not received by the EMG or ENB line. Configure the circuit in such a way that the drive source

will never be turned on when these contacts are open.

When turning on the power, turn on the control power first, confirm that these contacts are closed, and then

turn on the drive power. (If the control power and drive power are turned on simultaneously, an “E6D, Drive-

source cutoff relay error” may generate.)

Loading...

Loading...