16 Chapter 2 Installation and Cabling

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

3. Remove 20 mm of the insulation layer from both ends of the power cable, insert the cable

into the rearend sleeves of the bare crimp terminals, use the crimping pliers to tighten the

sleeves, and use heat shrink tubing to insulate the bare crimp terminals.

4. Use a screw driver to remove the protective cover of the aviation plug, remove 5 mm of the

insulation layer of the 7 cores, use a soldering iron to connect the 7 cores of the control

cable to the 7 pins of the aviation plug, use heat shrink tubing to insulate the bare parts,

install the protective sleeves of the 7-core control cable, and restore the protective cover of

the aviation plug.

5. Insert the gas tube through the two hose clamps and use a screw driver to fix each of them

at100 mm away from each end of the tube.

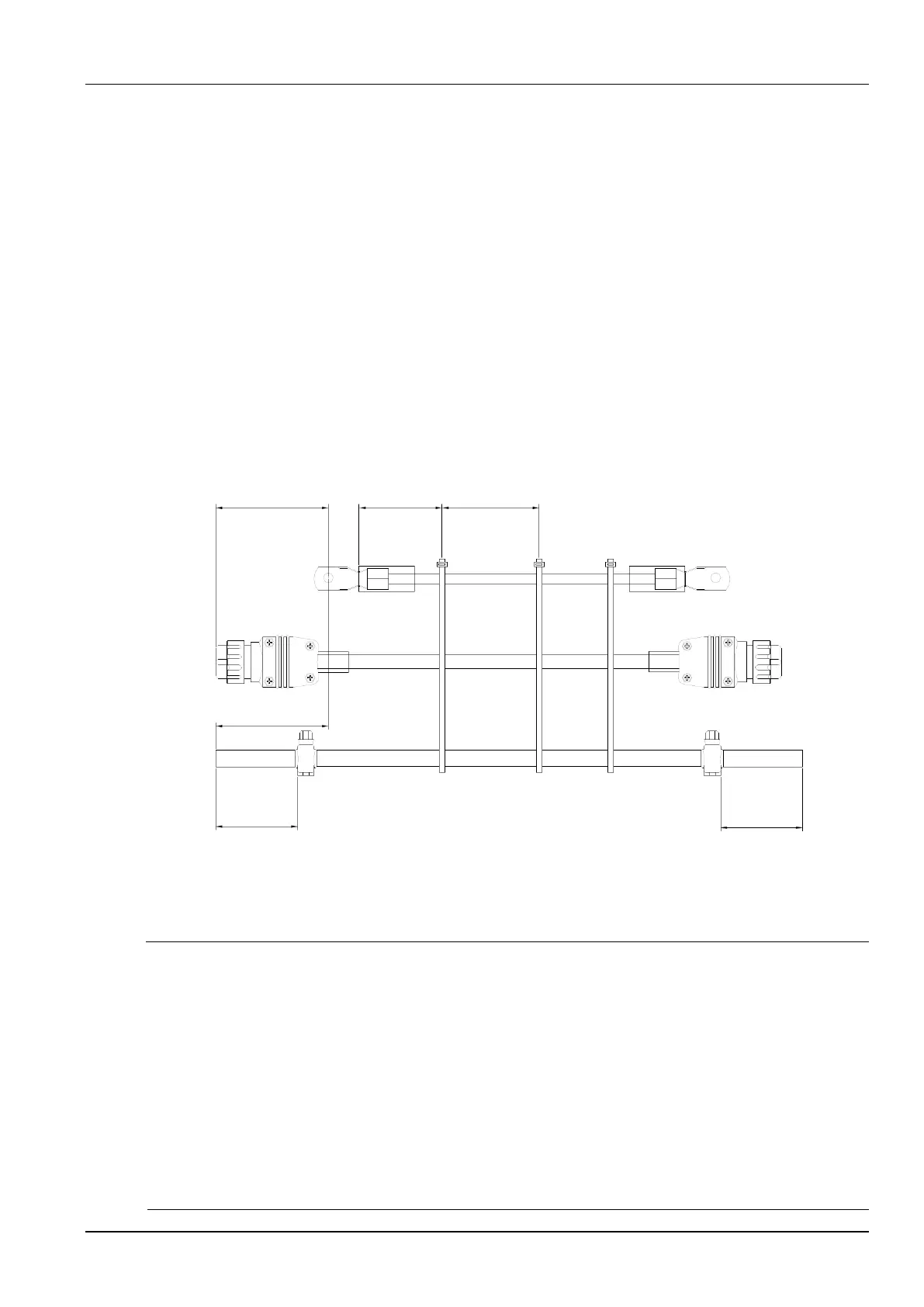

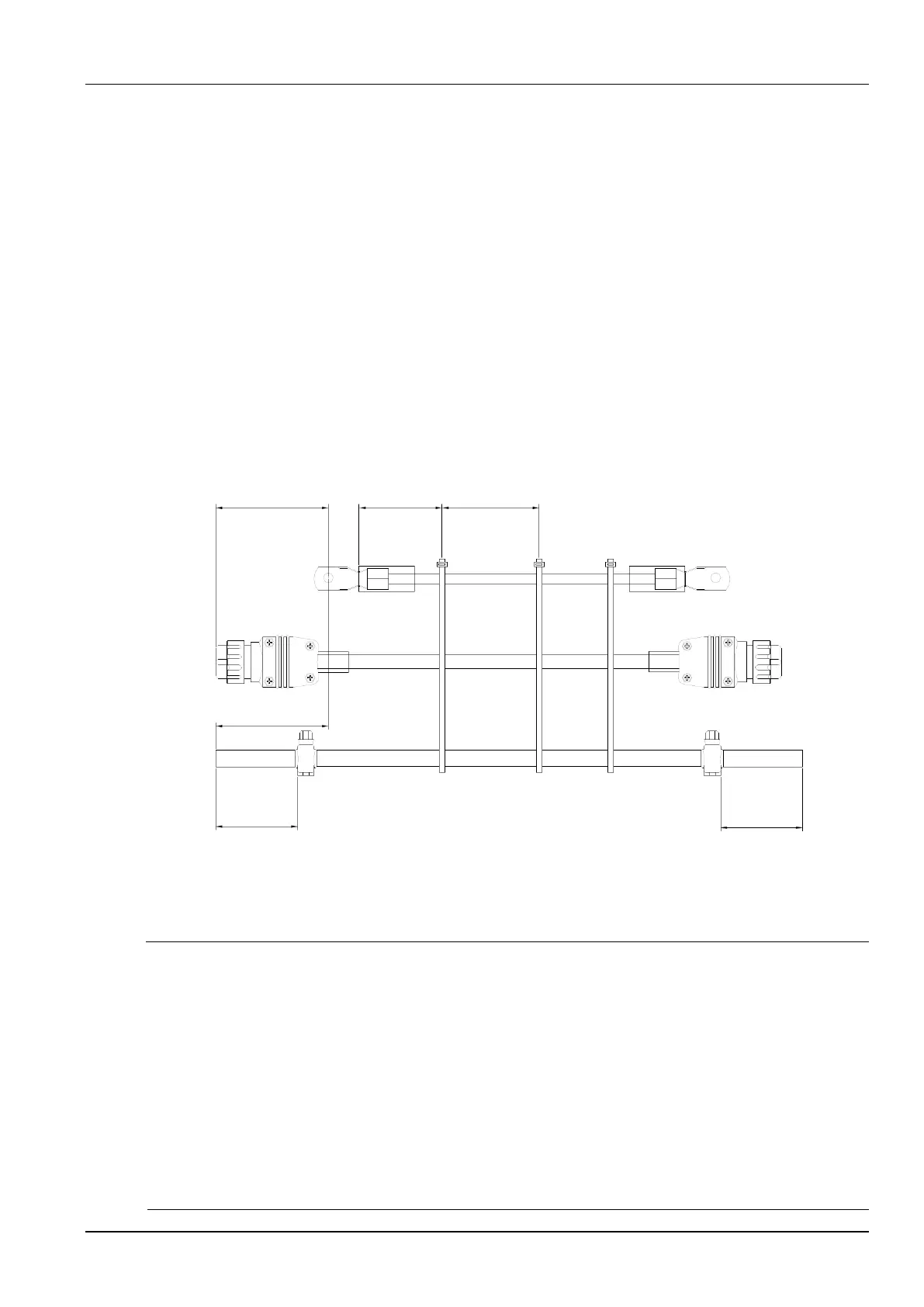

6. Use cable ties to tie the cables and tube together at every 600 mm. At the end connected to

the wire feeder, the 7-core control cable must be 110 mm longer than the power cable and

the gas tube must be 110 mm longer than the power cable. At the end connected to the

welder, the excessive lengths of the control cable and gas tube are not handled. Figure 2-2

shows the way to tie the cables and tube.

600 mm 600 mm110 mm

110 mm

100 mm

100 mm

Power cable

Protective

sleeve

Cable tie

Gas tube

End connected to the wire feeder

Clamp

7-core aviation plug

Bare crimp terminal

Connected to the welder power supply

7-core control

cable

Figure 2-2 Schematic diagram of tying cables and tube

2.6 Electric Connections

Safety Warning

1. Connections must be set up by certified professional electric device operators.

2. Electric connections can be set up only after the distribution box is switched off and necessary safety

measures are taken.

3. Use specified cables.

4. Do not touch electric connections with wet hands.

5. Do not place heavy objects on the power cables.

6. Running water pipes and reinforcing bars of houses may not be adequately grounded. Do not

connect grounding cables to them.

7. Each welder is equipped with one air circuit breaker or fused switch.

Loading...

Loading...