Chapter 4 Maintenance 63

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

Chapter 4 Maintenance

4.1 Daily Inspection

Safety Warning

Daily inspection (except for appearance inspection that does not require contact of electrical conductors)

can be performed only after the distribution box power supply and welder power supply are turned off.

This aims to prevent injuries such as electric shocks and burns.

Usage Notes

1. Daily inspection is key to ensuring high performance and operation safety of the welder.

2. Perform daily inspection based on the items specified in the following table. Perform

cleaning and component replacement when needed.

3. To ensure high performance of the welder, use only the components provided or

recommended by Megmeet when replacing components.

Welder

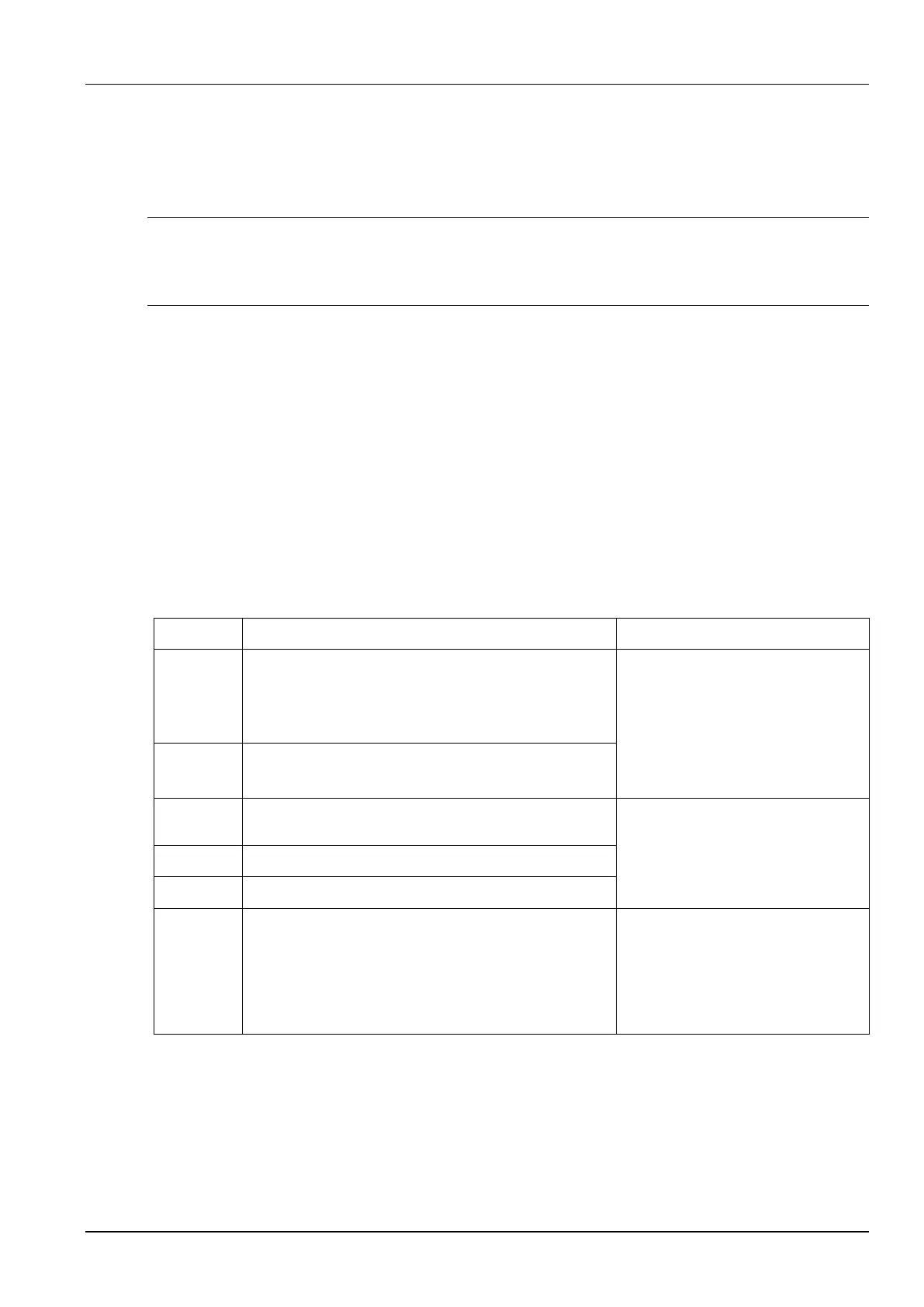

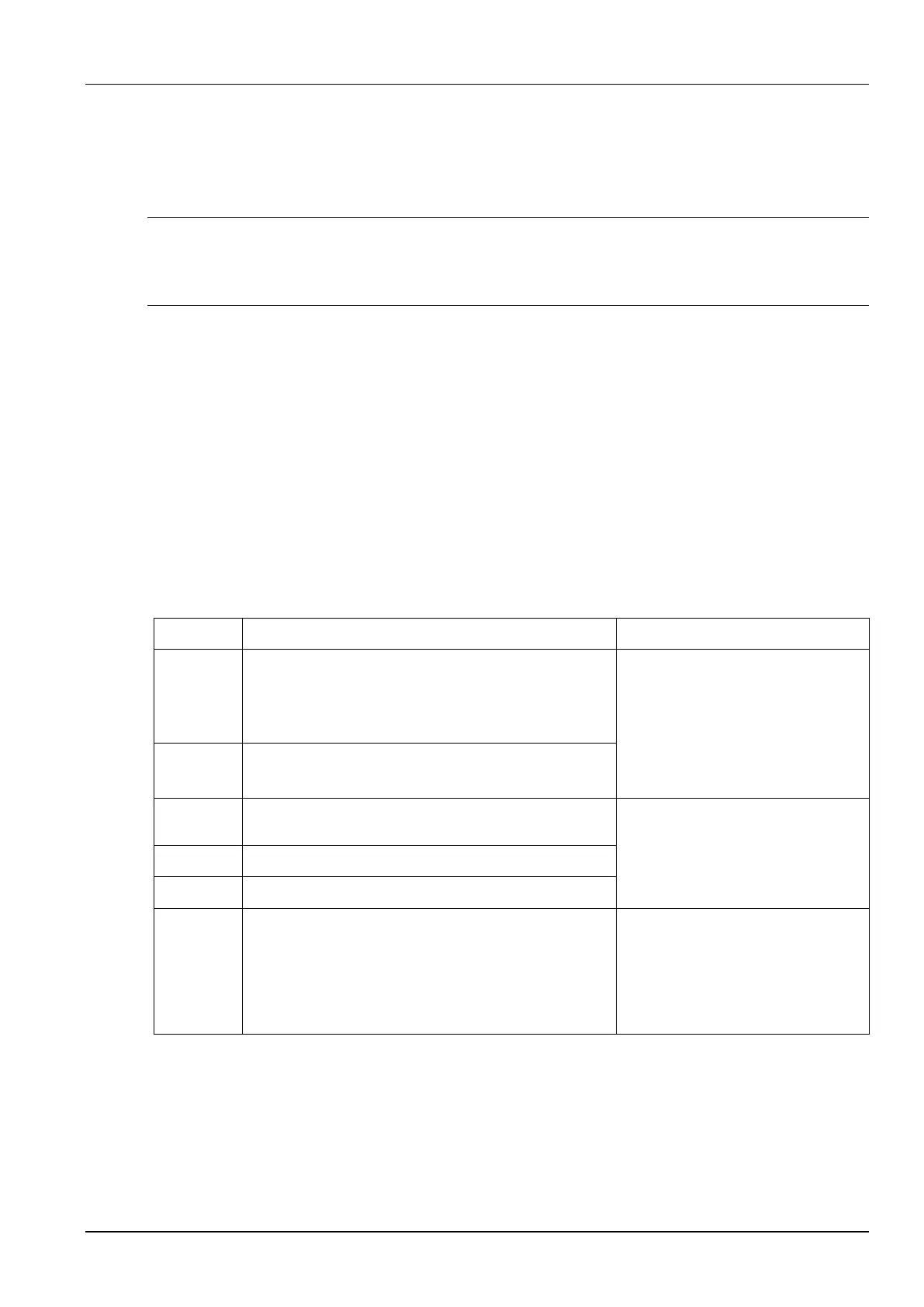

Table 4-1 Daily inspection on the welder

Check whether the mechanical components are damaged

or loose.

Check whether the cables at the lower part are fastened.

Check whether the fault indicators flash.

Regularly check the components

under the terminal cover at the lower

part. If an issue is detected, perform

internal inspection on the welder, and

fasten or replace components.

Check whether the power supply terminal cover is intact.

Check whether the air vent is blocked.

Check whether the hoist ring bolts and the other bolts are

loose.

If an issue is detected, fasten or

replace components.

Check whether the casters are damaged or loose.

Check whether the side panels are loose.

Check whether the appearance shows decolorization or is

overheated.

Check whether the sound emitted by the fan when the

welder is operational is normal.

Check whether a peculiar smell or unexpected vibration or

noises are detected when the welder is operational.

If an exception is detected, perform

internal inspection on the welder.

Loading...

Loading...