Chapter 4 Maintenance 69

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

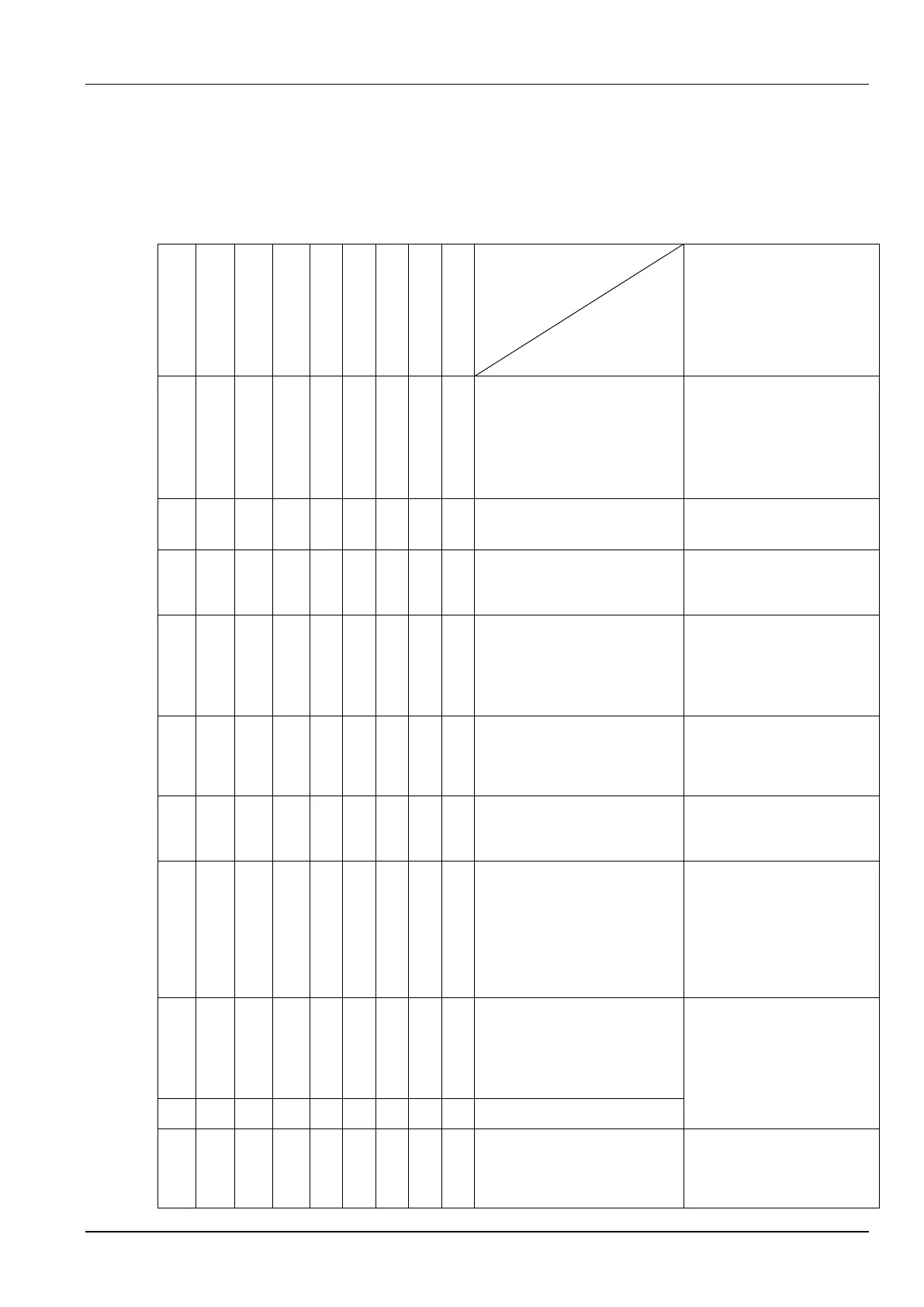

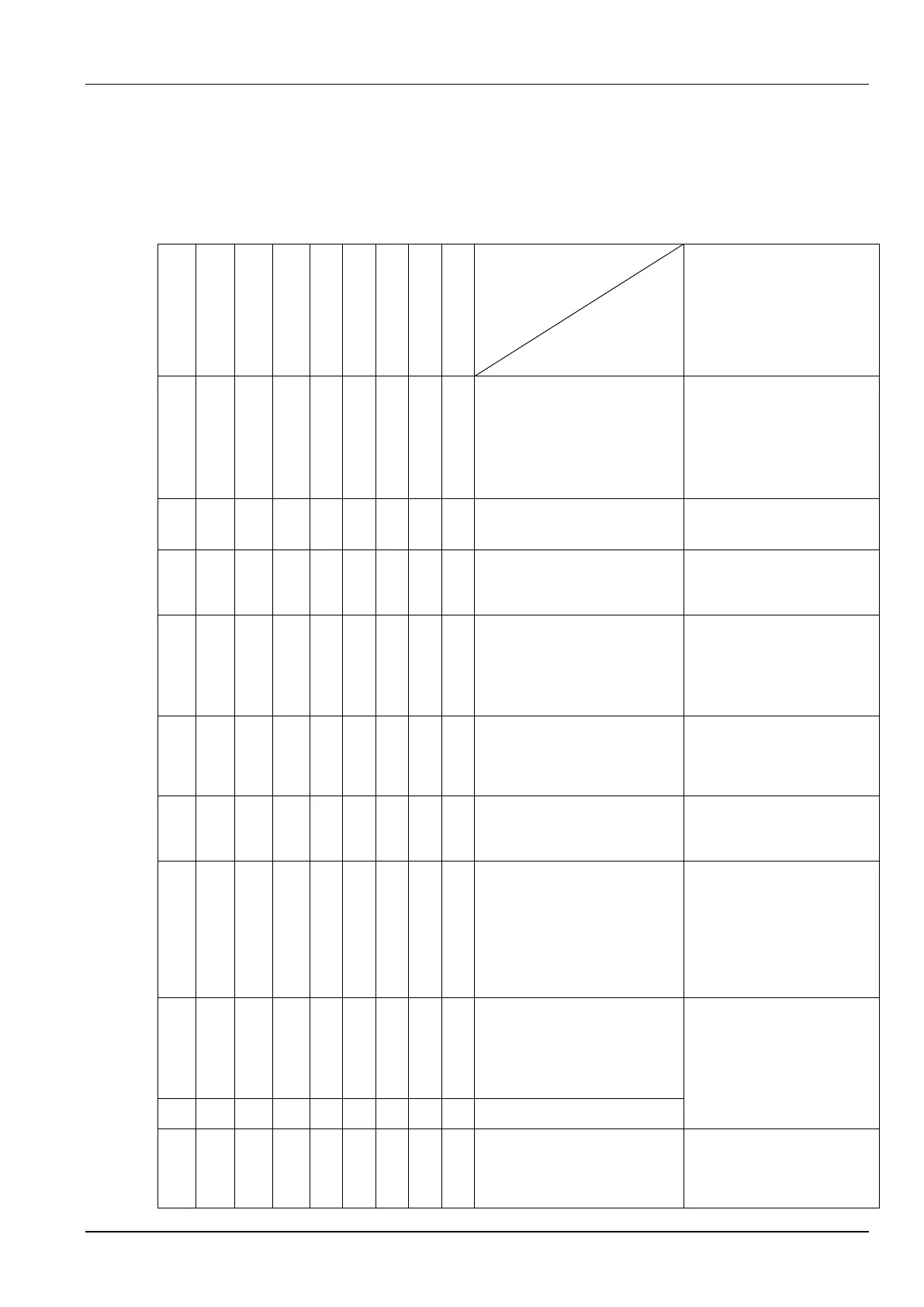

4.3.3 Rectifying Welder Faults and Welding Process Issues

When the welder is faulty or fails to perform self-identification, perform the checks specified in

Table 4-6.

Table 4-6 Welder fault symptoms

Starting arc

generation failure

Sticking between

wire and workpiece

Sticking between

wire and tip

Fault Symptom

Check Content

Related Component or

Environment

The switch is not turned on or is

tripped.

The fuse is blown.

Phase loss occurs on the

three-phase power supply.

The connection is loose.

The cable is disconnected.

The connection is loose.

The switch is not turned on or is

tripped.

The fuse is blown.

The main valve of the gas cylinder is

not opened.

The gas volume is insufficient.

The gas purity does not meet the

requirement.

The gas flow control by the regulator

is inappropriate.

The connection to the gas tube or

gas cylinder is loose.

Electrically-heated CO

2

regulator

The gas tube is broken.

The connection to the regulator or

wire feeder is loose.

The wire inching roll and wire liner

do not match the wire diameter.

The wire inching roll is broken or the

groove is blocked.

The force imposed by the strut bar

of the wire inching roll is insufficient.

The inlet of the wire liner is blocked.

The welder power cable or welding

torch power cable is broken.

The connection to the wire feeder is

loose.

The cables are damaged.

Welder power cable and welding

torch power cable

Excessive roll-up or bending occurs.

The tip and wire liner do not match

the welding wire.

The tip or wire liner is worn out,

blocked, or deformed.

Loading...

Loading...