Chapter 3 Welder Operation Description 41

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

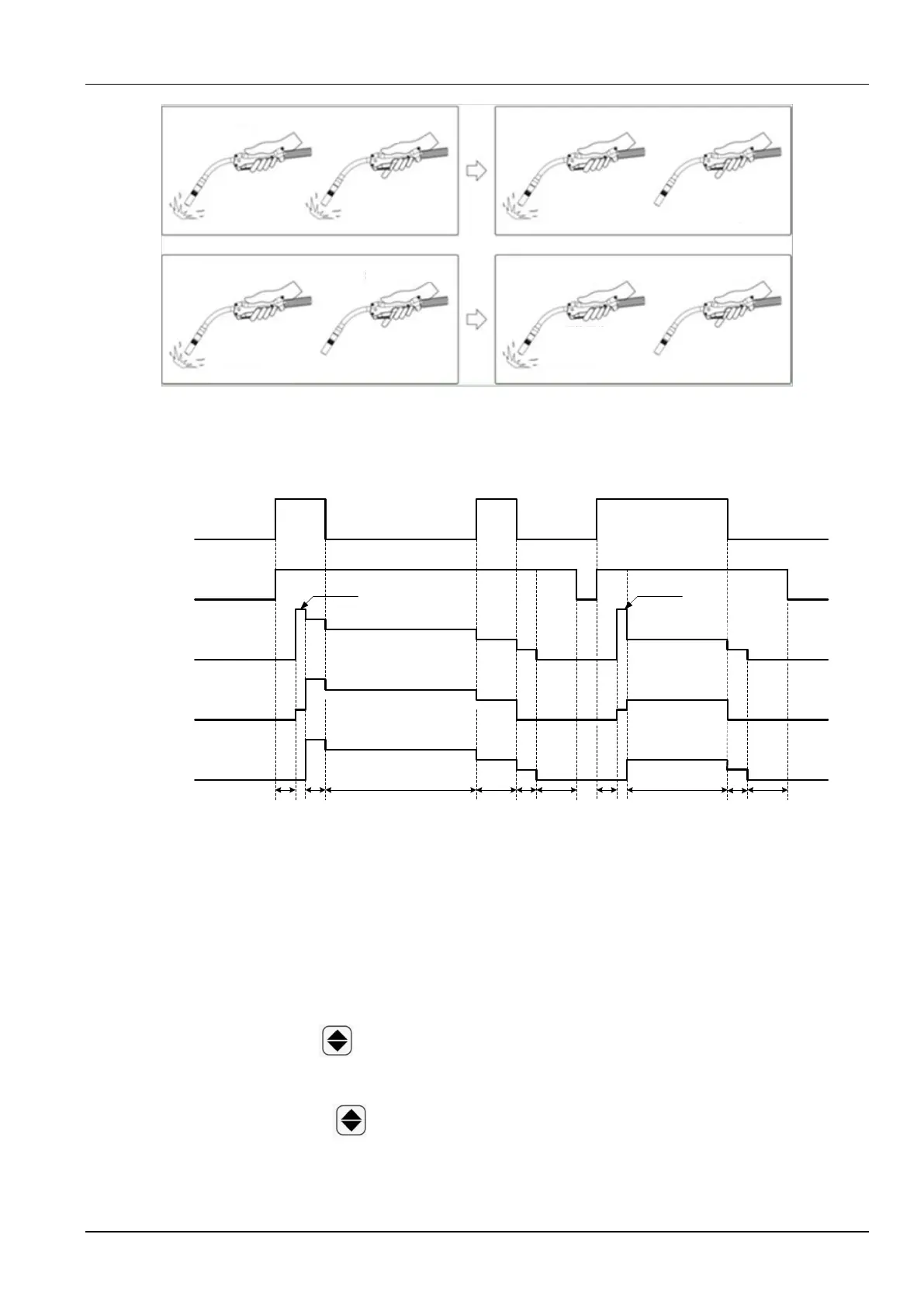

Welding arc is

generated.

Turn on the

power switch of

the welding

torch.

Turn off the

power switch of

the welding

torch.

Switch to the ending arc.

Turn on the

power switch

of the welding

torch again.

Turn off the

power switch of

the welding

torch again.

Welding stops.

Welding arc

generation is

locked.

Ending arc is

generated

again.

Turn on the power

switch of the

welding torch

within 2 seconds.

Turn off the

power switch of

the welding

torch again.

Welding stops.

Ending arc is

generated

again.

Turn on the power

switch of the

welding torch again.

Welding stops.

Turn off the

power switch of

the welding

torch again.

Repeated within 2 seconds

Figure 3-14 Schematic diagram of welding with repeated ending arc

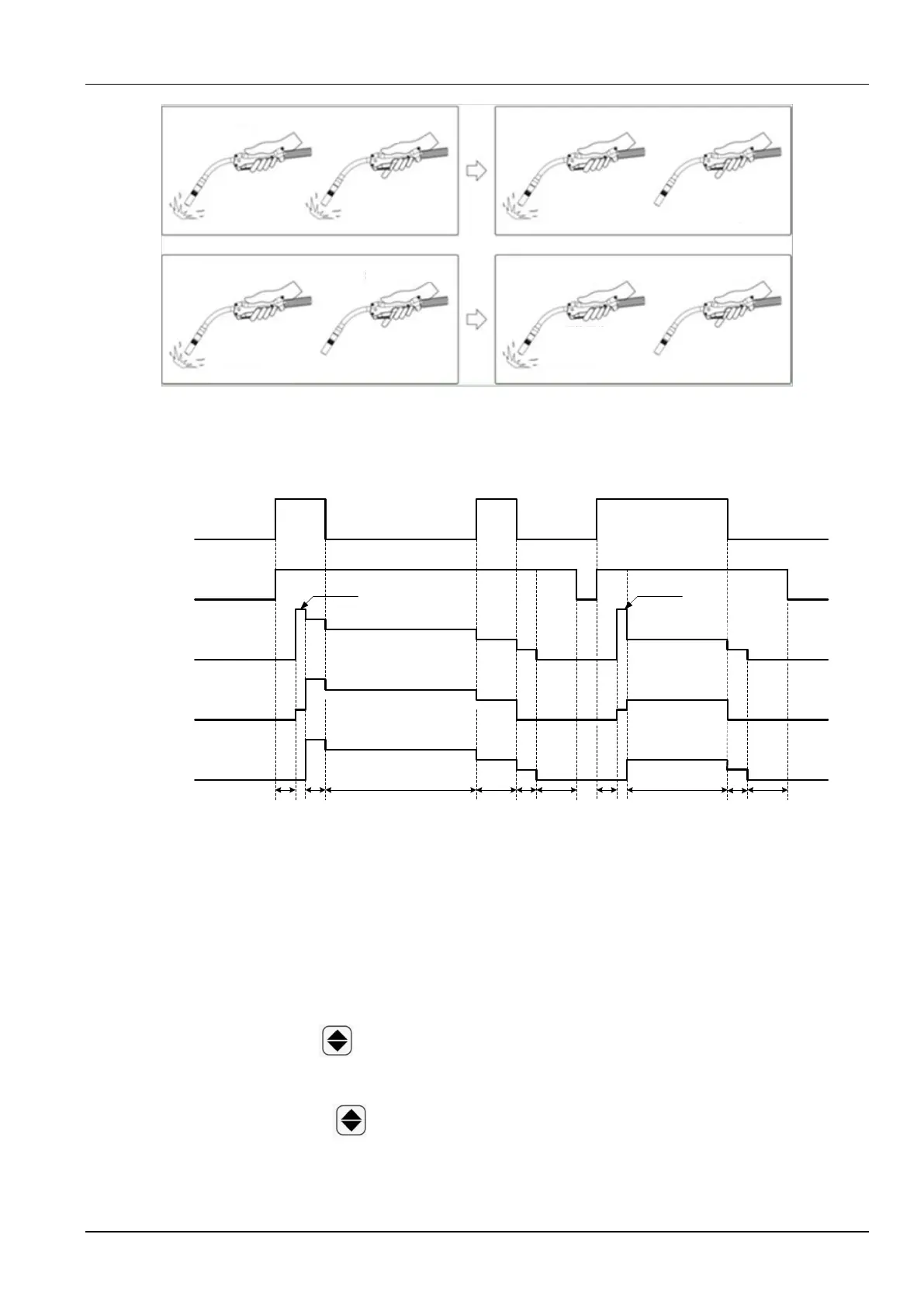

Figure 3-15 shows the welding logic.

Welding

torch

switch

Gas

sending

Welding

voltage

Wire

inching

speed

Welding

current

Send gas

before

welding

Open circuit voltage

Starting

arc

Weld

Wire sticking

prevention

OFF

ON

OFF

Delayed gas

sending

ON

OFF

Ending

arc

ON

OFF

Delayed gas

sending

Wire sticking

prevention

Ending

arc

Open circuit voltage

Send gas

before welding

Figure 3-15 Logic for welding with repeated ending arc

3.4.6 Synergic/Manual

Synergic

The welding voltage varies with the welding current. The procedure is as follows:

1. Press the Manual button on the control panel and rotate the voltage adjusting knob on

the wire feeder to set the standard voltage to 30 V.

2. Press the Synergic button on the control panel and perform welding in synergic

mode.

Loading...

Loading...