Chapter 2 Installation and Cabling 25

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

Voltage

(

V

)

Standard

Manual/Synergic

tuning

Inch wire

Wire inching

button

Current

(A

)

Adjust current

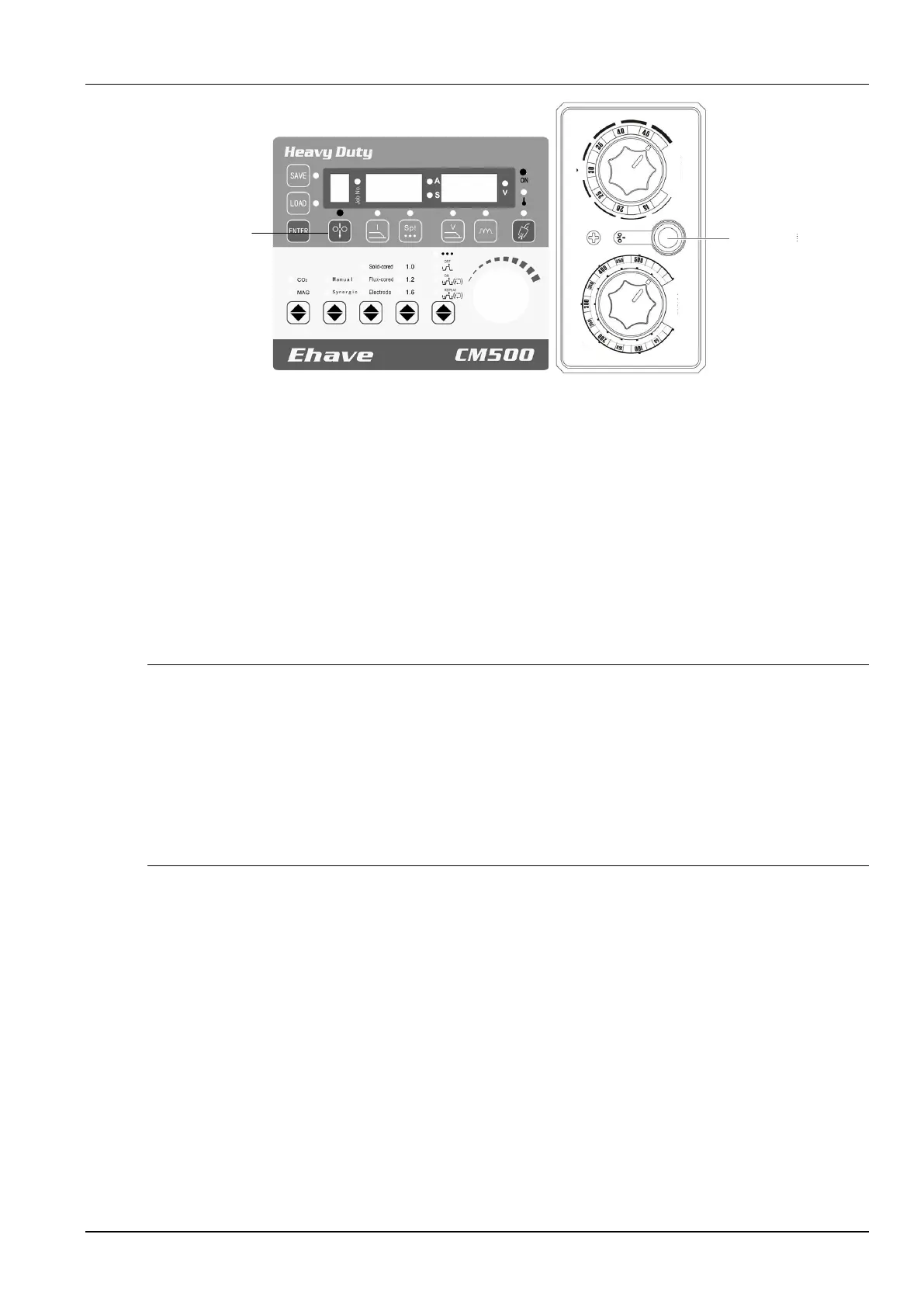

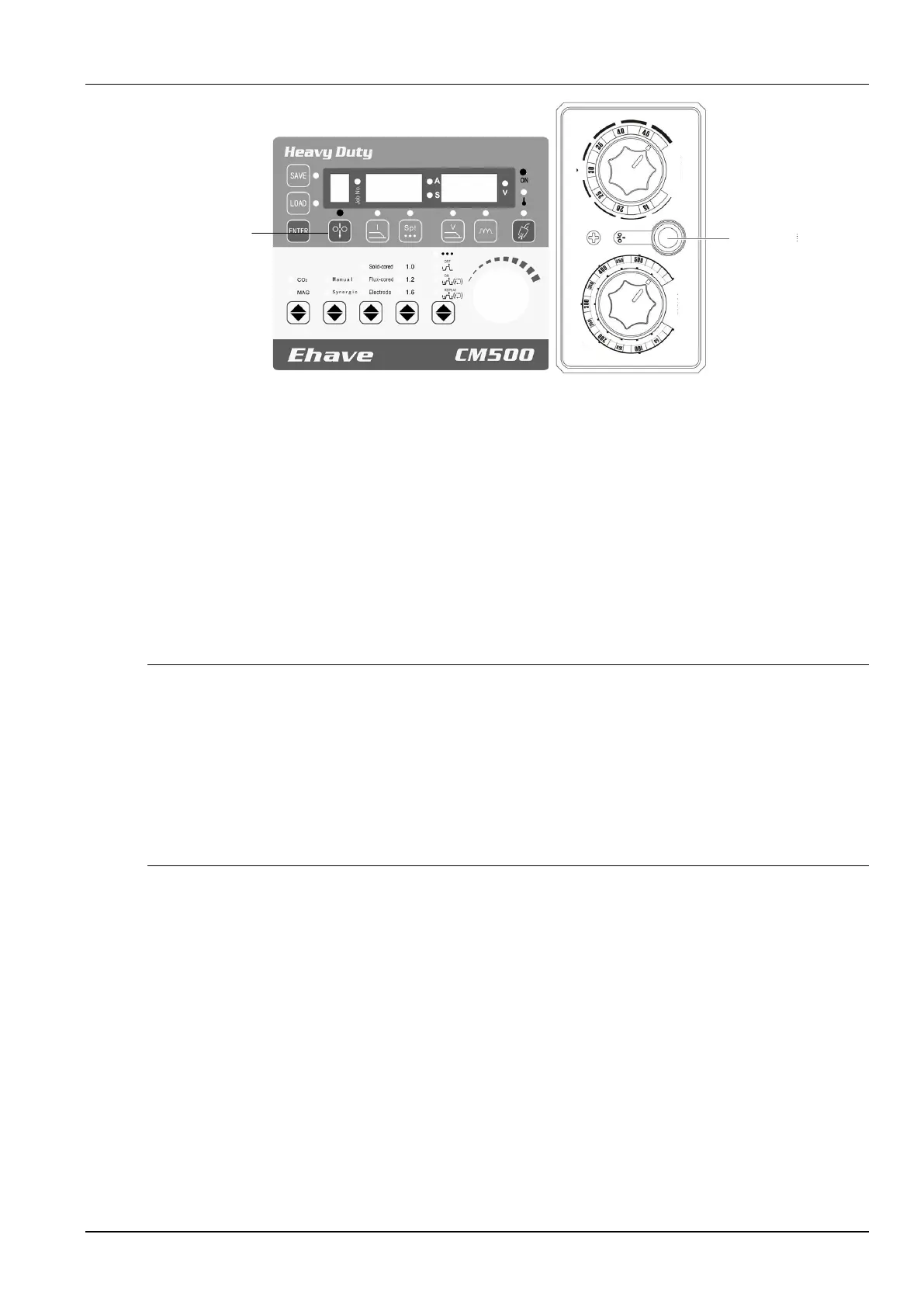

Figure 2-12 Position of the wire inching button

Usage Notes

1. The wire inching roll must match the wire diameter and selection of the wire inching roll does

not depend on the welding wire type.

2. Use the wire inching pressure lever to adjust the pressure of the wire inching roll according

to the wire diameter. For details, see the wire feeder user manual.

3. If you use a flux-cored wire, use the lever to reduce the pressure to slightly lower than that

for a solid wire.

Safety Warning

1. Do not check at a short distance whether the wire has been extended through the tip; otherwise, the

wire may injure your eyes or skin.

2. When you use a welding torch with a resin wire inching tube to manually inch wire, stretch the power

cable of the welding torch and set the wire inching speed (current) to less than half of the rated value,

so as to prevent the wire from piercing the wire inching tube and welding torch power cable in case

that the welding torch power cable is excessively bent.

3. Upon finding a crack in the welding torch power cable or wire inching tube, replace the damaged

cable or tube.

2.7.6 Welding Conditions

Under the standard welding conditions, the welding parameters in the following tables are

applicable, including the common parameters for CO

2

welding (solid wire), MAG welding (solid

wire; Ar 80% + CO

2

20%), and flux-cored wire. In actual welding projects, modify the

parameters according to the workpiece materials, workpiece shapes, and welding positions. If

high welding quality is required, you are recommended to determine the optimal welding

process parameters through tests. The wire diameter adopted for the actual welder shall

prevail.

Loading...

Loading...