58 Chapter 3 Welder Operation Description

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

3.6.2 Safety Protection Function for the Welding Torch

After startup, if the welding torch is turned on but is not used within 10 seconds, the main power

output is disabled. This ensures safe usage.

3.6.3 Slow Wire Inching

In the period between startup of slow wire inching and starting arc generation, the wire inching

speed is slower than that in the welding period. Slow wire inching aims to increase the starting

arc generation success rate and reduce fusion problems in the arc welding startup section of a

weld.

Note

Slow wire inching can be customized based on user requirements.

3.6.4 Connecting a Robot

Note

The standard configuration of the Ehave series does not allow connection to robots. If you need to

connect the welder to a robot, you must purchase Ehave CM350AR/500AR or other series dedicated to

automatic welding.

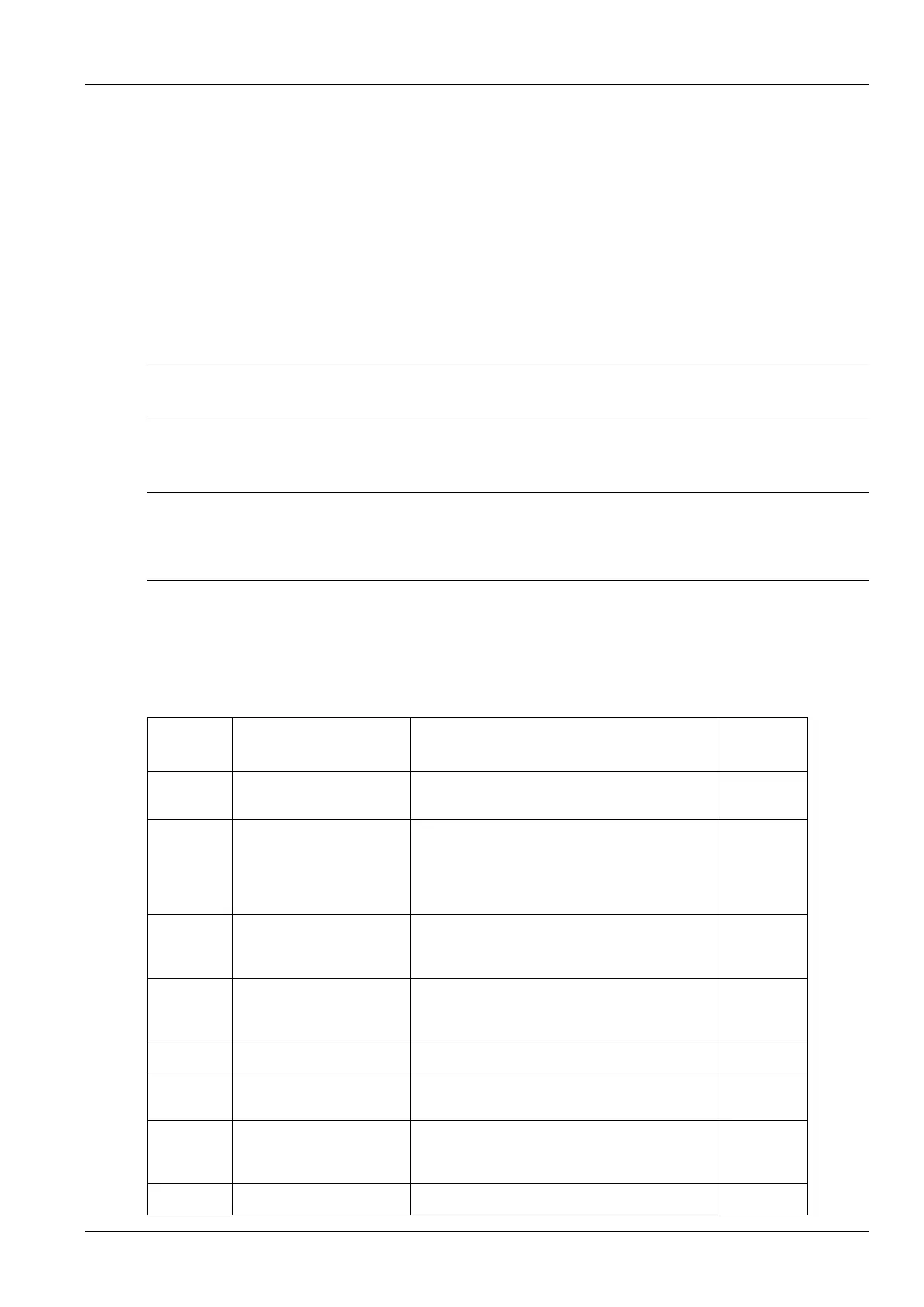

Ehave CM350AR/500AR can be connected through the DB15 communication terminal on the

rear panel to the analog interface of a welding robot. Figure 3-48 show the pins of the DB15

connector. Table 3-3 describes the pins.

Table 3-3 Definition of the pins of the DB15 connector

Power signal provided by a welding robot to the

welder.

Starting arc generation

signal

I/O signal provided by a welding robot to the

welder to control the welder power output.

When it is set to OFF, it is effective in case of a

low level. When it is set to ON, it is effective in

case of a high level.

Reverse wire inching

signal

I/O signal provided by a welding robot to the

welder to reverse the wire inching motor. It is

effective in case of a low level.

Starting arc generation

success signal

I/O signal provided by the welder to a welding

robot to indicate starting arc generation

success. It is effective in case of a low level.

Common grounding

signal of analog signals

Common grounding for the analog signals of

pins 7, 13, 14, and 15.

Analog signal provided by the welder to the

robot to indicate the actual welding current

value.

Common grounding for the I/O signals of pins

Loading...

Loading...