Chapter 3 Welder Operation Description 47

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

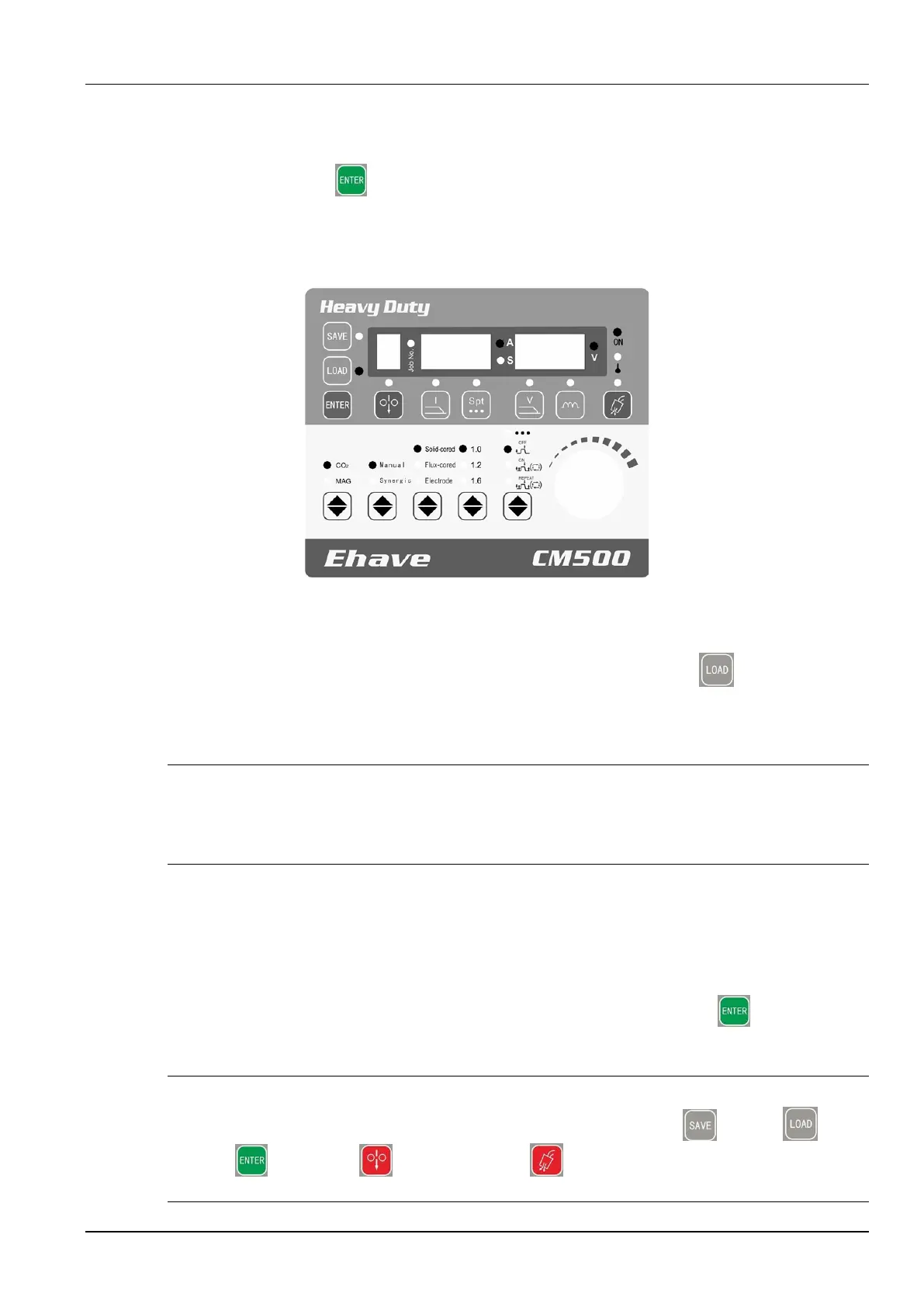

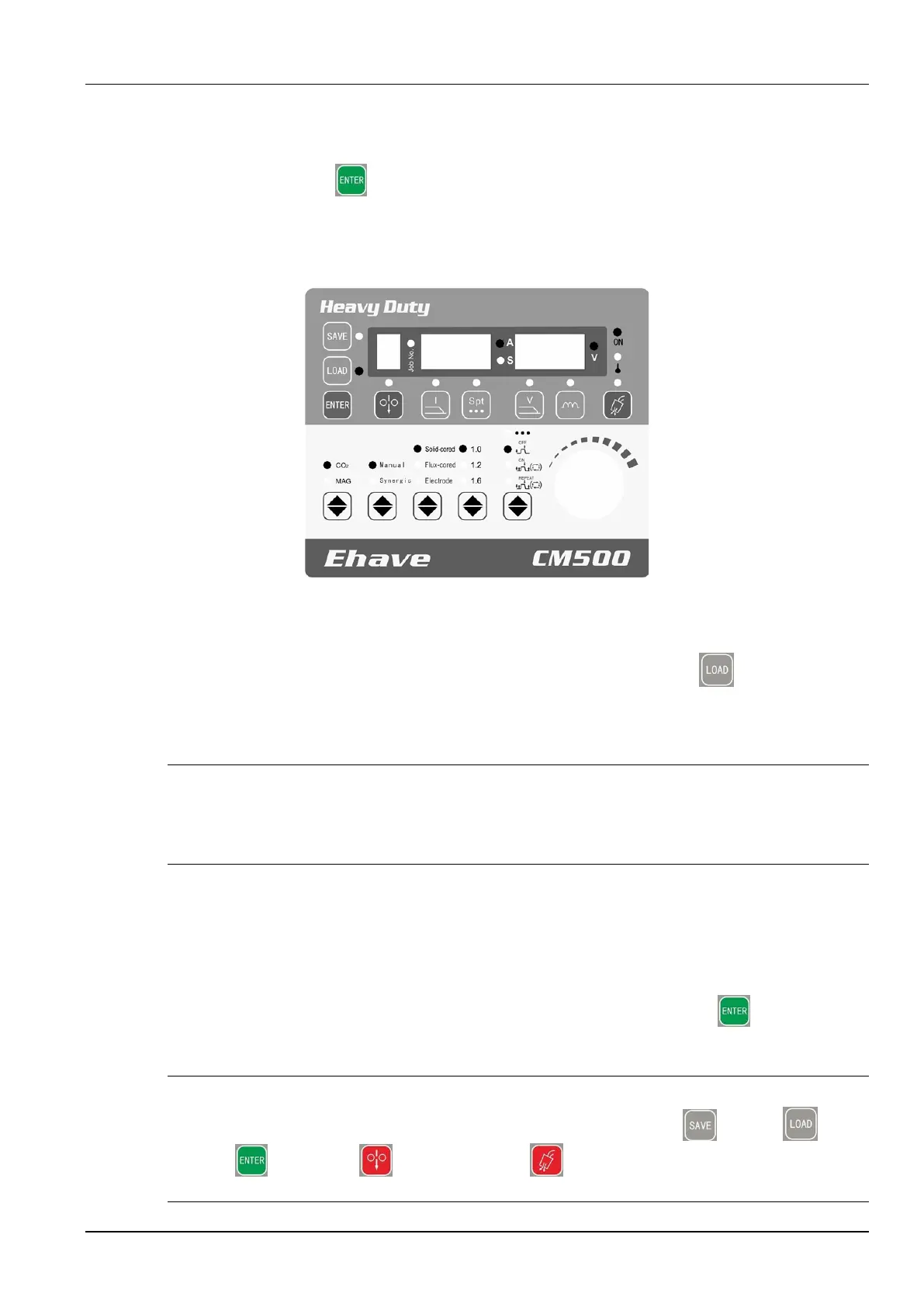

2. Use the knob to select a channel number (0 - 9) and the parameter settings saved to the

channel appear.

3. Press the ENTER button to load the parameter settings. To view parameter settings,

directly press the corresponding function buttons.

4. Figure 3-22 shows the control panel where the parameter settings are loaded.

SAVE

Feed

wire

Job No.

ON

Over-

temperature

Manual

MAG

LOAD

ENTER

Ending

arc

current

Spot

welding

time

Ending

arc

voltage

Arc

dynamic

Detect

gas

Synergic

CO2

Solid wire

Flux-cored

wire

Electrode

Spot welding

Welding without

ending arc

Welding with

ending arc

Repeated

welding with

ending arc

Gas type

Output

control

Wire

type

Wire

diameter

Welding

control

Figure 3-22 Loading parameter settings

Note:

To abort the loading operation during the procedure, press the LOAD button.

3.4.11 Lock

Safety Warning

1. If you set a lock password, it is not deleted when the factory settings of the welder are restored.

2. Keep your password properly. If you forget your lock password, the welder cannot be unlocked. In

this case, contact the manufacturer or supplier.

Parameter locking can be implemented with the common lock or password lock.

Purposes of the locking function:

1. The common lock only prevents the parameter settings completed on the control panel of

the welder from being changed. You can press and hold the ENTER button to

unlock.

Note

In common lock mode, all the buttons and knobs (expect the SAVE , LOAD ,

ENTER , Inch wire , and Detect gas buttons) on the control panel of the

welder cannot be used.

Loading...

Loading...