30 Chapter 2 Installation and Cabling

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

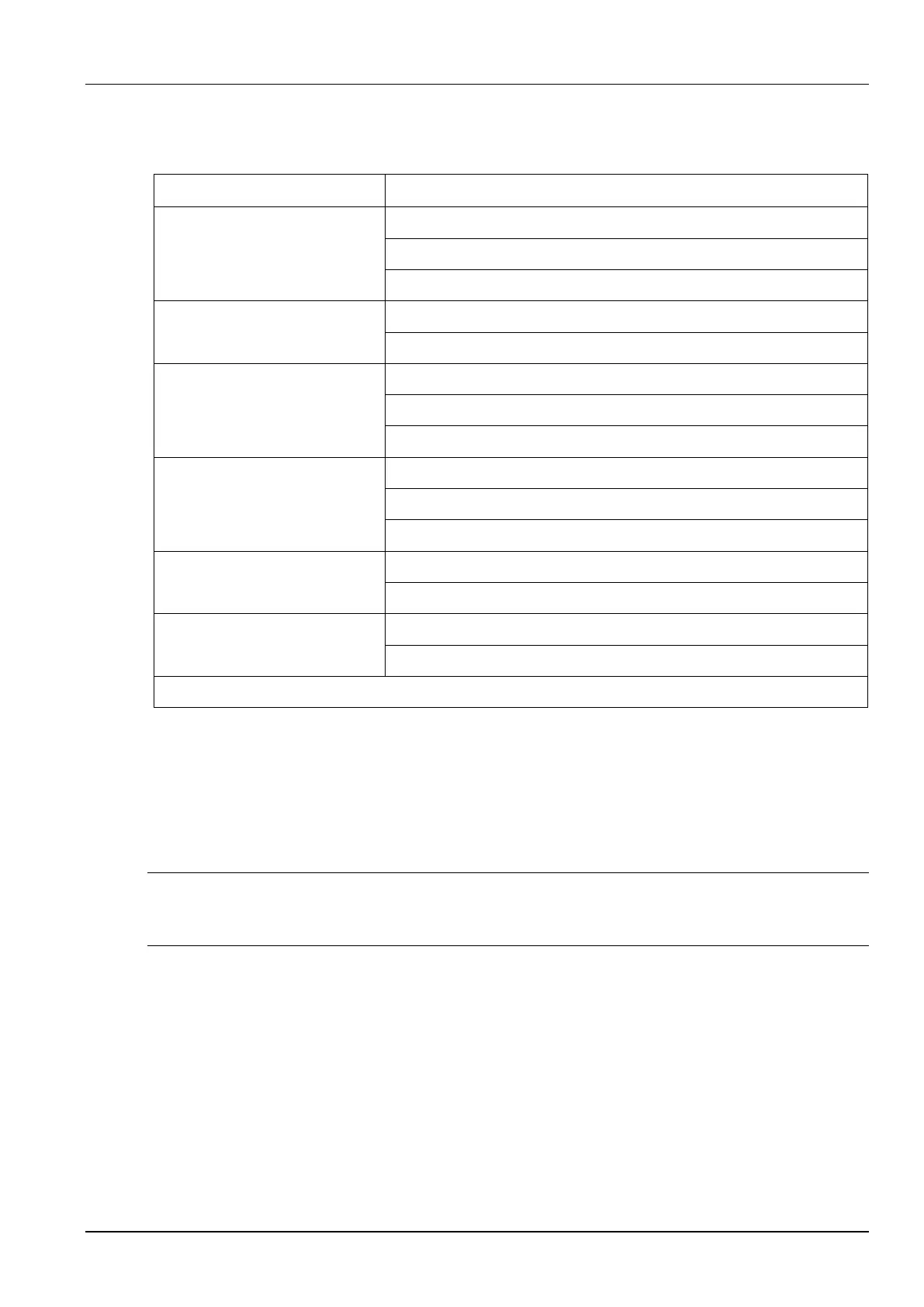

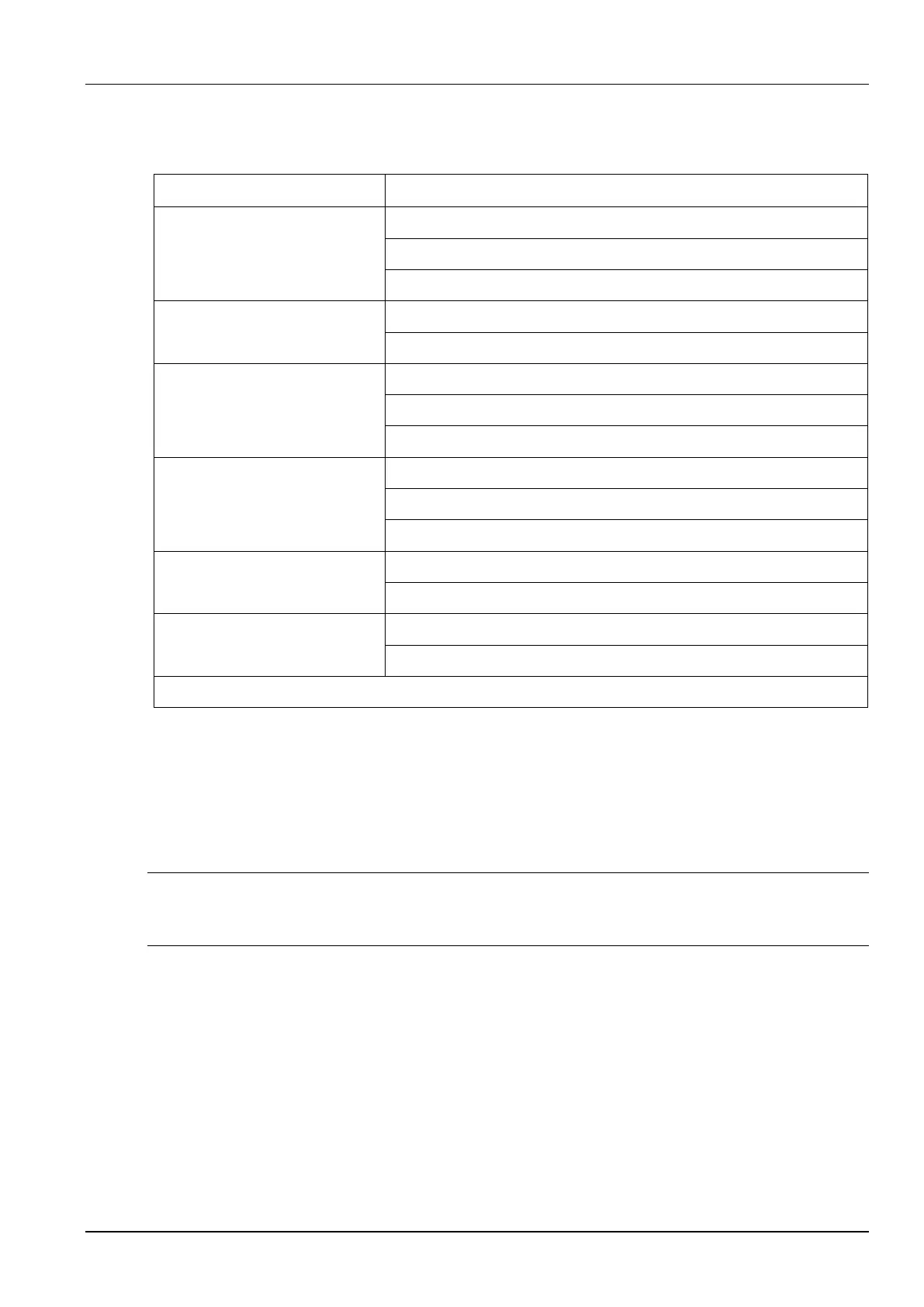

Table 2-6 describes the issues that occur when the welding conditions are abnormal.

Table 2-6 Abnormal welding conditions

Abnormal Welding Condition

Wire stick-out is excessive.

The protection performance of the gas decreases.

Wire stick-out is inadequate.

The arc voltage is excessively

high.

The fusion depth and reinforcement are reduced.

The arc voltage is excessively low.

Wire sticking and spatters occur.

The fusion depth and reinforcement are reduced.

The welding current is excessively

high.

The fusion depth and reinforcement are increased.

The welding speed is excessively

high.

The fusion depth and reinforcement are reduced.

Wire stick-out: distance between the tip and the workpiece to be welded

2.8 Post-welding Tasks

Turn off the main switch of the gas cylinder and then turn off the power switch.

Turn off the power supply of the welder and then the power supply of the distribution box.

Note

Do not turn off the power supply of the welder until 3 to 5 minutes after welding is complete. This

facilitates internal cooling of the welder.

Loading...

Loading...