Chapter 4 Maintenance 67

Ehave Series Full Digital IGBT CO

2

/MAG/MMA Multifunctional Inverter Welder User Manual

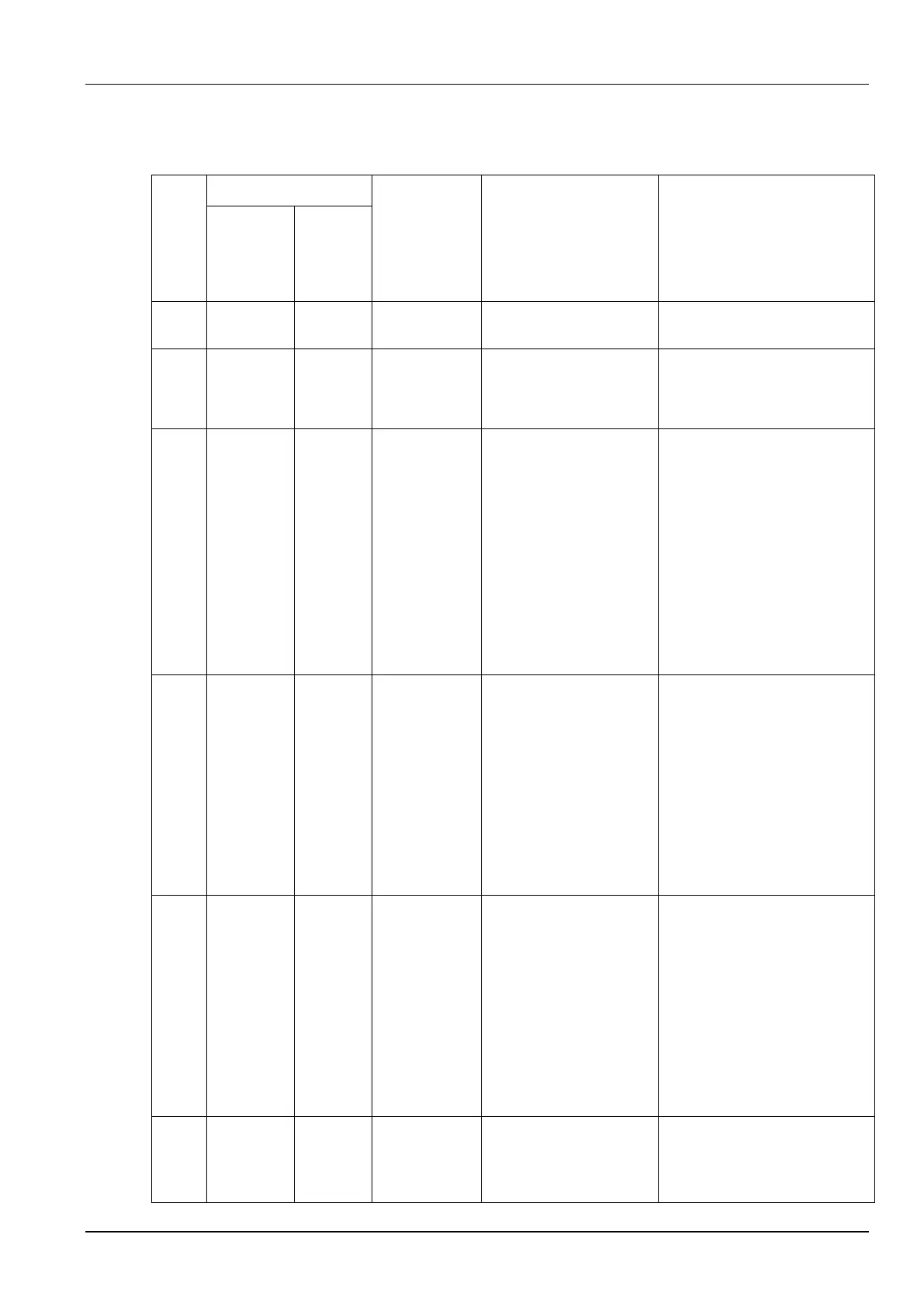

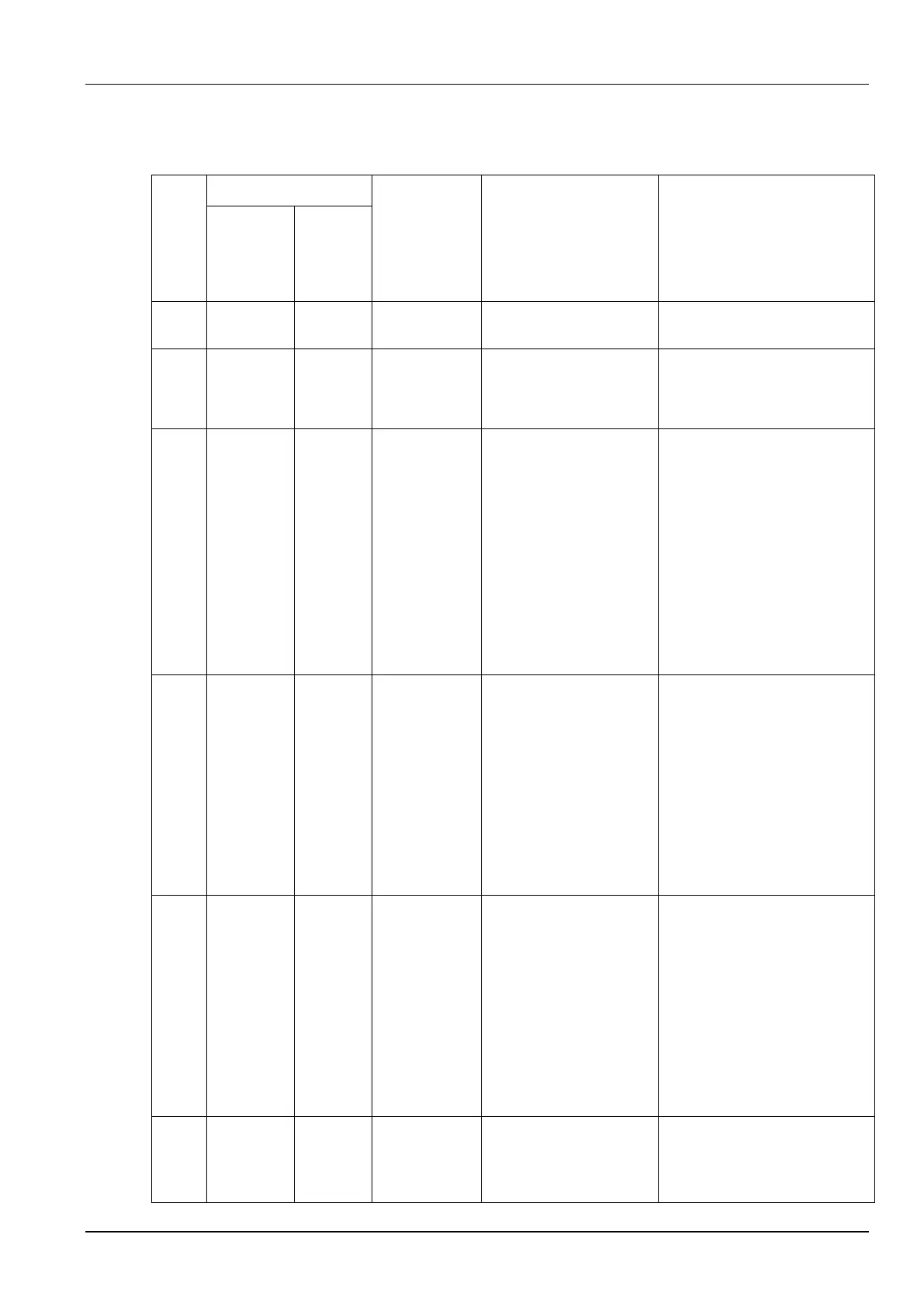

Table 4-5 describes the welder error codes as well as causes and solutions.

Table 4-5 Welder faults, causes, and solutions

Three

Nixie

Tubes in

the Middle

Screen

Three

Nixie

Tubes in

the Right

Screen

When the welder is

turned on, the welding

torch power switch is on.

The switch is broken.

Turn off the switch.

Replace the welding torch.

Output

terminal

over-temperat

ure

The output terminal and

power cable are

disconnected or the

screw is not fastened.

The copper

cross-sectional area of

the output power cable is

too small.

The output cable terminal

fails to meet the

specification requirement.

The fan does not work or

slows down.

Reliably fasten the output

terminal.

Use cables with greater

cross-sectional areas.

Select suitable cable terminals.

Verify that the fan works

properly.

The input power cable is

not connected properly.

Input power overvoltage

occurs.

Input power undervoltage

occurs.

Input power phase

imbalance occurs.

The input power

frequency exceeds the

range.

Verify that the input cables are

connected properly.

Verify that the input power is

normal.

IGBT or diode

over-temperat

ure

The rated duty cycle is

exceeded.

The air vent of the

housing is blocked.

The radiator is covered

with heavy dust.

The fan does not work or

slows down.

The IGBT or diode

current is excessively

high.

Ensure that the welder works

within the rated duty cycle

range.

Verify that the air vent of the

welder is not blocked.

Remove dust from the radiator.

Verify that the fan works

properly.

Verify that the main power board

and output diode module are

normal.

A button is jacked up.

A button does not

rebound after being

pressed.

Check the buttons

corresponding to the numbers

(displayed on the right screen)

shown in Figure 3-1.

Loading...

Loading...