MICRO S automatic Cutter motor

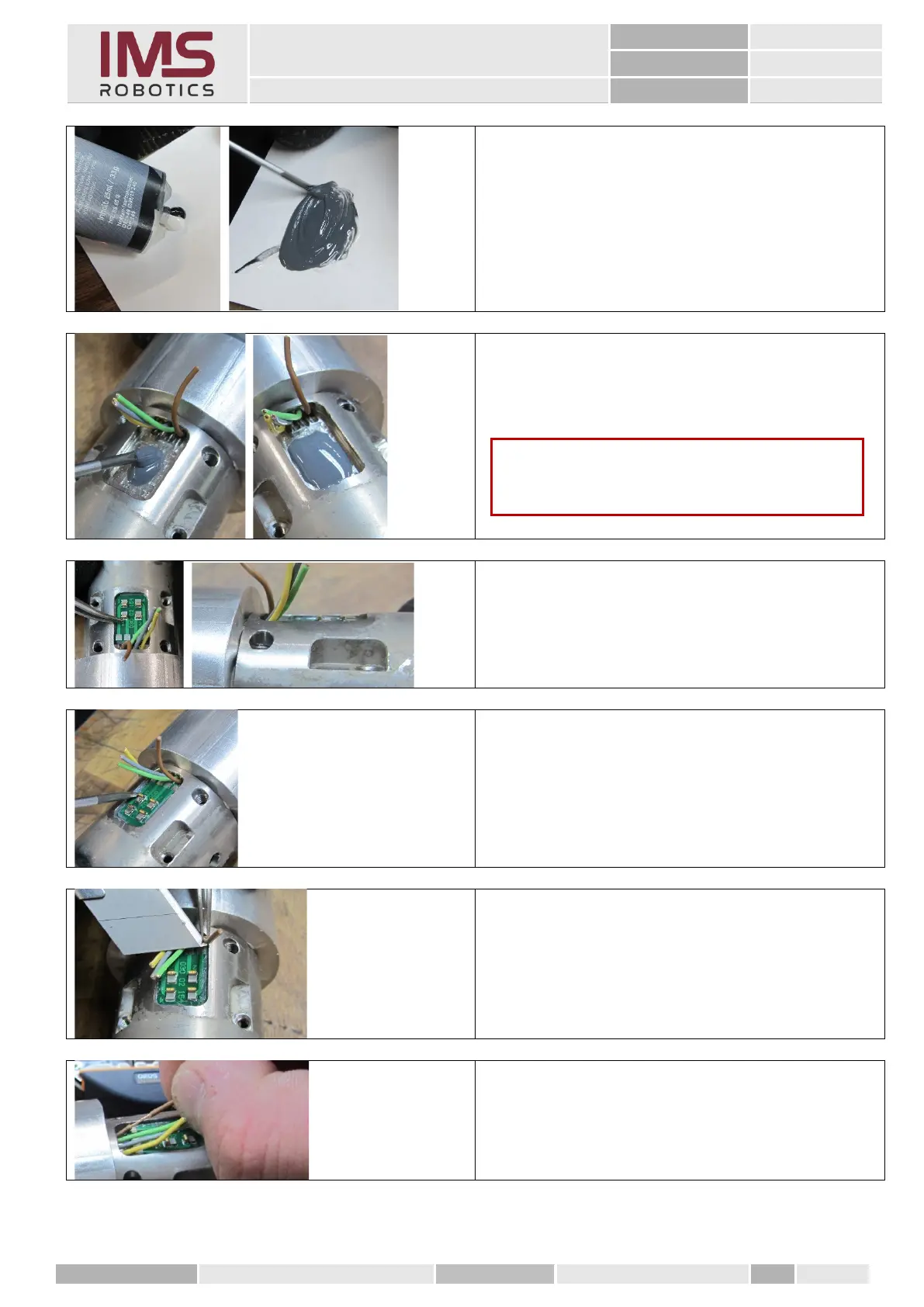

1. Apply a suitable two-component

adhesive (e.g. "Toolkraft Flüssigmetall"

made by Toolkraft)

of the size of a cherry seed onto a clean

surface and mix evenly.

Processing time about 5 min.

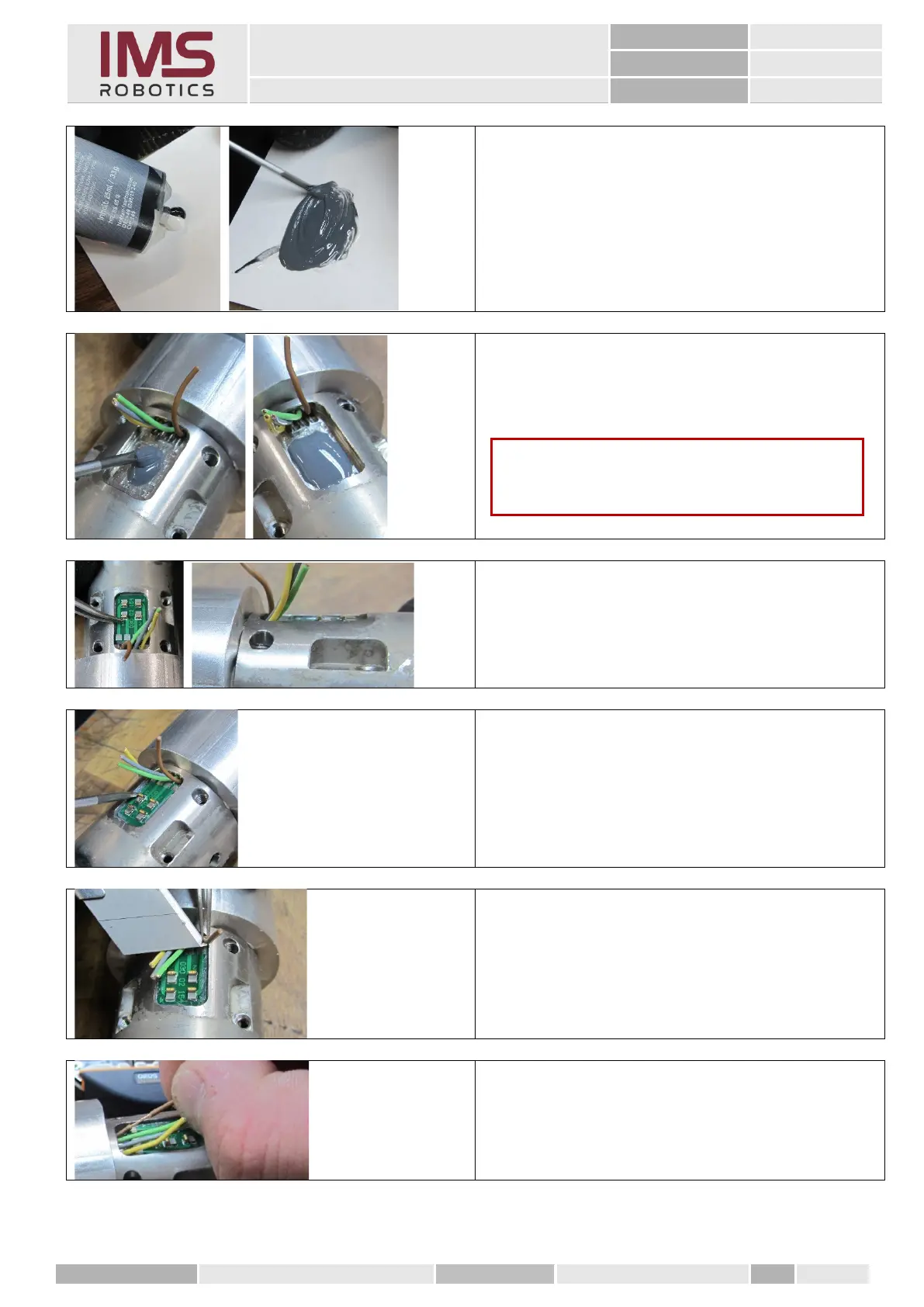

2. Now pour the well mixed adhesive into

the slot for the spring contact PCB.

3. The PCB has to be positioned right at the

front and the spring contacts have to

protrude a bit over the air motor

housing.

4. Remove excess material after about 5

minutes, depending on the adhesive

used.

The adhesive should not smear any more

but also should not be completely firm.

You can start soldering after about 15 - 20

minutes, when the adhesive has hardened

sufficiently.

1. Carefully cut the sheathing so that the

wires are not damaged.

2. Strip only a small section and twist it.

Caution

Use the right amount of glue because the board

will float in the glue and be fixed.

Loading...

Loading...