JOHNSON CONTROLS

17

FORM 155.17-N1

ISSUE DATE: 4/1/2013

3

SECTION 3 – UNIT RIGGING

Only qualied rigging personnel should

handle the rigging operation. Failure

to observe this may result in equipment

damage, serious injury or death!

For unit weights and dimensions, see Table 3 on page

87 in Appendix A at the back of this document.

Rigging diagrams for specific ParaFlow™ unit mod els

are located in Appendix B (Figure 44 on page 95 )

The following guidelines must be followed when rig-

ging the unit:

1. When using single point lifting, do not place the

slings at more than a 60° angle. See diagrams in

Appendix B for illustration.(Figure 44 on page

95 )

2. If slings will be at more than a 60° angle, use

spreader bar.

3. Only rig the unit horizontally! Do not slant the

unit while moving it. If the unit is to be installed

in a sub lev el basement or where it can only be

rigged slanted, contact Johnson Controls for spe-

cial instructions prior to rigging. This should be

done prior to ordering, to check feasibility.

4. Lifting eyes are mounted at the top of the “S”-

type se ries units for rigging. Choose a chain ac-

cording to the min i mum length requirement in

column “C” under the “S” Unit Rig ging table.

Place the hooks in the eyes and lift unit to the ap-

pro pri ate lo ca tion.

5. Do not sling on or against any projecting brack-

ets, pumps, valves, pipes, ttings, etc.

6. Do not lift the unit using the holes at the corners

of the end sheets. These holes are manufacturing

lift ing holes and are not designed for lifting the

com bined weight of a completely as sem bled unit.

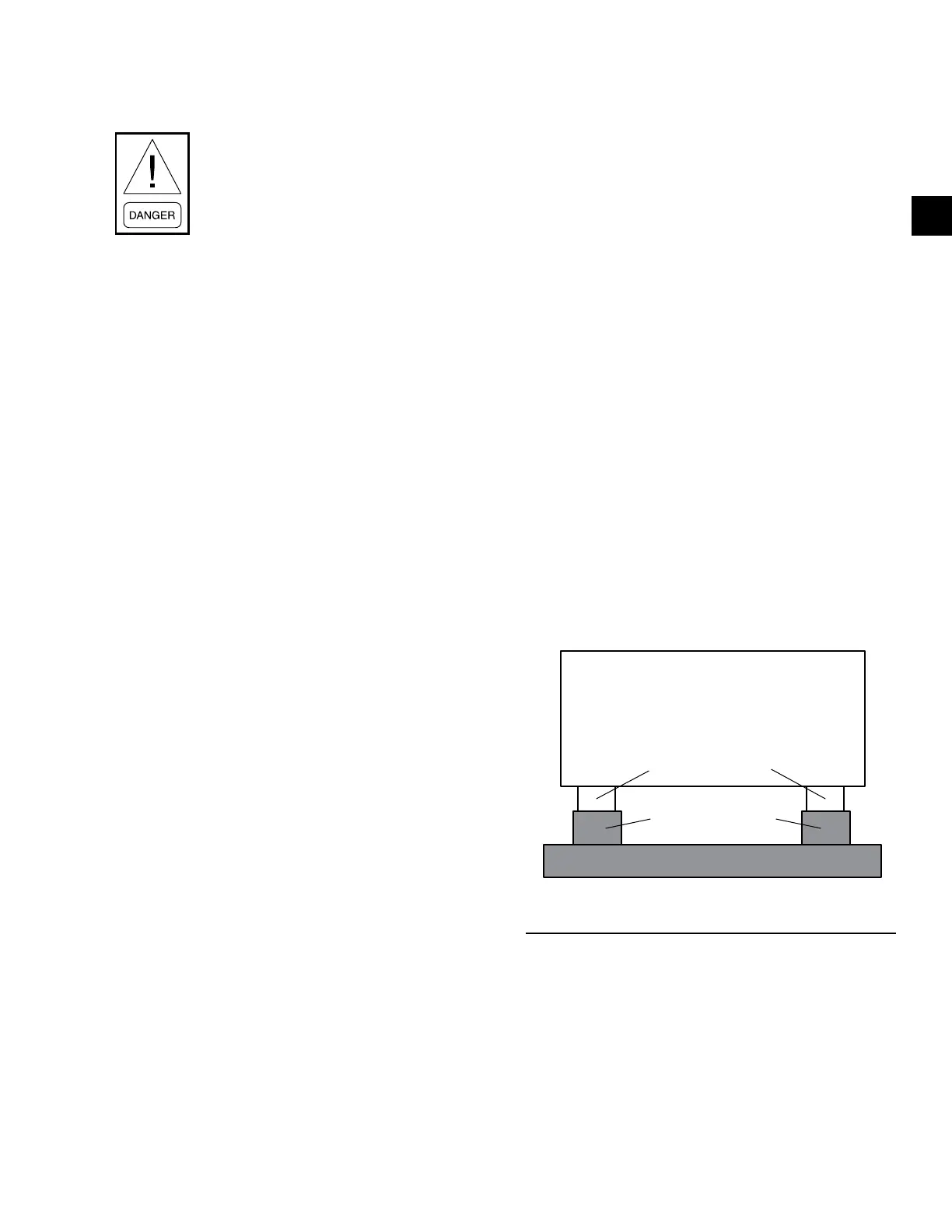

FOUNDATION

Unit foundations are usually made from concrete with

a compressive strength rating of not less than 4000 psi

and are able to support the full operating weight of

the unit (see Ap pen dix A Table 3 on page 87– Unit

Weights and Di men sions, for the par tic u lar unit mod-

el). When lay ing a con crete foun da tion, use steel to

reinforce the con crete and fin ish the sur face smooth ly.

The con crete foun da tion pad must be lev el with in 1/4

inch at all the mount ing lo ca tions of the unit.

If the ceiling height in the equipment room per mits,

it is advantageous to have a por tion of the foun da tion

el e vat ed just where the chill er legs will set upon the

con crete. This allows for greater clear ance be neath the

chiller for service work such as tak ing so lu tion sam-

ples, pulling pumps, etc. For de tails on where the chill-

er feet will rest (chill er foot print), see the ap pro pri ate

YORK “Di men sions and Phys i cal Data” forms as list-

ed in the Introduction Section of this doc u ment.

See the ap pro pri ate ta ble in Ap pen dix A Table 3 on

page 87 at the back of this doc u ment for unit di men-

sions, and weights.

YORK ParaFlow

Chiller/Heater

TM

CHILLER FEET

ELEVATED SECTIONS

(Risers)

FOUNDATION PAD

FIGURE 3 - FOUNDATION PAD

ld05297

Loading...

Loading...