JOHNSON CONTROLS

82

SECTION 29 – ELECTRICAL CONNECTIONS

FORM 155.17-N1

ISSUE DATE: 4/1/2013

FLOW SWITCHES

The ParaFlow

TM

chiller/heater must mon i tor the flow

of water through the various heat ex chang er bundles in

order to operate correctly. There fore, flow switches or

differential pressure control switch es are re quired on

the chilled water, tower water and hot water (if ap pli-

ca ble) flow circuits to determine if flow is established.

The chilled water flow switch is a safety control. It

must be connected to prevent operation of the unit

whenever chilled water flow is stopped. One Chilled

Wa ter flow switch for each unit is al ways sup plied by

YORK and in clud ed with the unit’s ship loose parts. A

dif fer en tial pressure control switch, tower wa ter flow

switch, or a hot water flow switch (if ap pli ca ble) can

be pur chased through YORK as an extra or der op tion.

Oth er wise, the tower wa ter and hot water flow switch-

es must be sup plied by oth ers.

For in stal la tion of these switch es, re fer to the Unit Wa-

ter Pip ing and Hook-up section of this doc u ment. For

wir ing, con nect the chilled water flow switch to termi-

nals 1 and 12 on TB2 of the Digital Input Board. This

board is lo cat ed in side the unit mi cro panel.

For the tower water flow switch, connect the wires

to terminals 1 and 20 on TB2 of the Digital Input

Board. The hot water flow switch (if applicable) would

be con nect ed to terminals 1 and 82 on TB4 of the

Relay Board. See Figure 43 on page 83.

All Flow devices contact ratings are to be

5 milliamperes at 115 volts A.C.

CONTROL OF CUSTOMER SYSTEM PUMPS

Since ab sorp tion chillers require a dilution cycle of an

unpredictable length of time, it is mandatory that the

ParaFlow

TM

micro panel control the operation of

the following system pumps:

• Condenser Water (Tower water)

• Chilled Water

• Hot Water (when applicable)

YORK’s prescribed method to employ this pump con-

trol is to hard wire the pump starter control circuit

through the appropriate contacts on the relay board.

See Figure 41 on page 82.

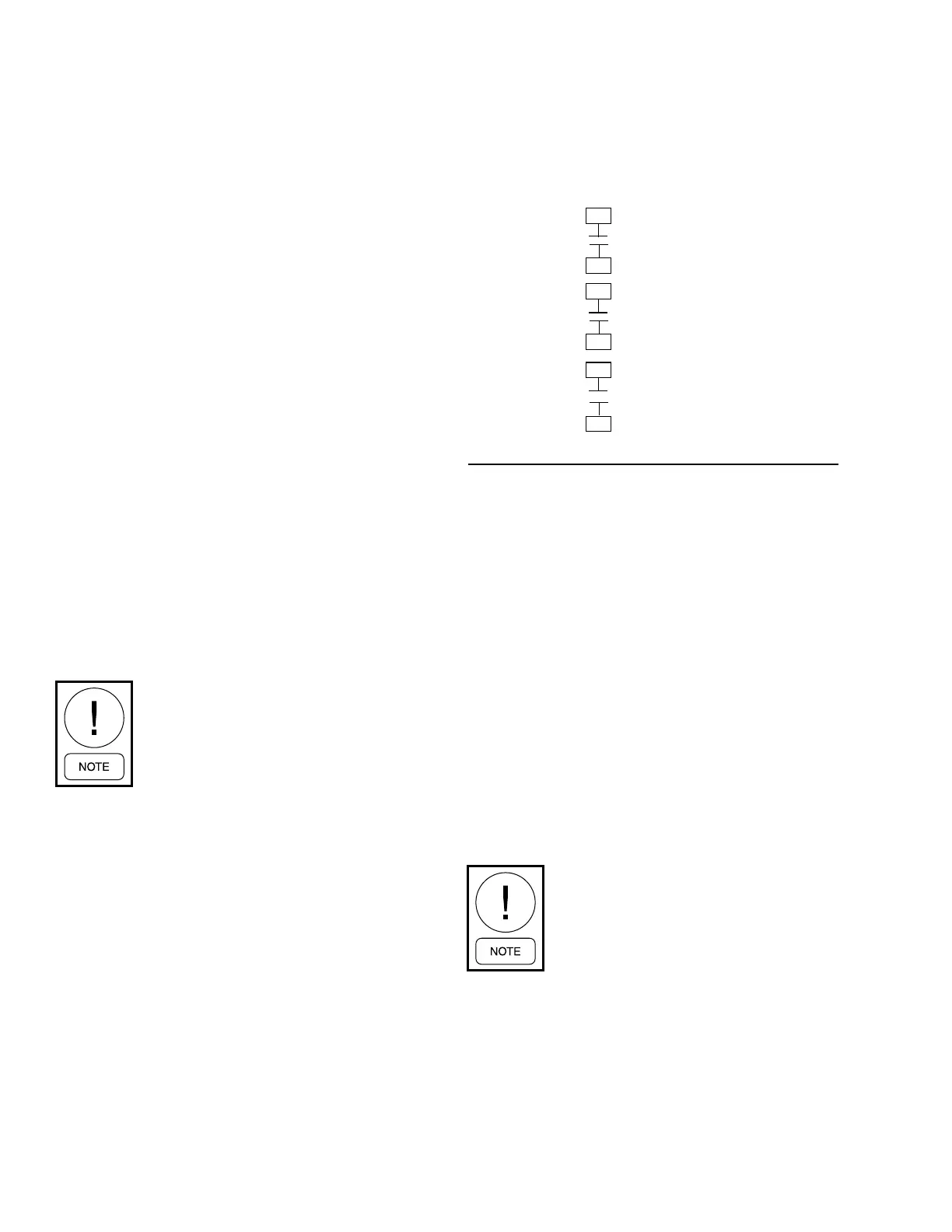

RELAY BOARD 031-01199-000

CONDENSER WATER

PUMP CONTACTS

HOT WATER

PUMP CONTACTS

CHILLED WATER

PUMP CONTACTS

55

56

87

88

44

45

FIGURE 41 - RELAY BOARD CONTACTS

LD05331

Should a customer insist on using another device,

such as an Energy Management System, to control the

pumps, that device must turn the pumps on and off as

a result of its direct interface with the contacts on the

relay board.

If there is a desire to interface the pumps with some de-

vice other than the ParaFlow

TM

micro panel, that device

must receive its instructions from the micro panel and

not from the Energy Management System.

Each con tact rat ing is 5 amps re sis tive at +/- 250 volts

A.C. and 30 volts D.C., 2 amp in duc tive (0.4 PF) +/-

250 volts A.C. and 30 volts D.C. Each 115 volt field-

con nect ed in duc tive load (i.e. relay coil, motor start er,

etc.) shall have a transient sup pres sor wired in parallel

with its coil, phys i cal ly lo cat ed at the coil. Spare tran-

sient sup pres sors and control cir cuit fuses are sup plied

in a bag in the control center.

Failure to adhere to the above

in struc tions could result in evaporator

tube freeze-up and unit crystalliza-

tion. Johnson Controls will not be re-

sponsible for damages to the unit, nor

cov er any charges under the unit war-

ran ty.

Loading...

Loading...