JOHNSON CONTROLS

71

24

FORM 155.17-N1

ISSUE DATE: 4/1/2013

Operation – The “R” indicates a modulating burner.

The burner will “modulate” infinite amounts between

its low-fire position and its high-fire position. YORK

always uses a modulating burner for the ParaFlowTM

chiller/heat ers.

Fuel Types – “G” indicates a gas burner – natural gas,

propane, or manufactured gas. The “L” indicates a #2

fuel oil burner. YORK ParaFlowTM chiller/heaters

that use oil, use only #2 fuel oil.

Burner Size – YORK ParaFlowTM chiller/heaters

use the following sizes:

3 = 300 - 2150 MBH

5 = 600 - 3200 MBH

7 = 1025 - 6000 MBH

8 = 1350 - 7650 MBH

9 = 1700 - 12000 MBH

10 = 3400 - 13500 MBH

11 = 4200 - 17400 MBH

30 = 1000 - 7300 MBH

40 = 1500 - 8700 MBH

50 = 2000 - 12600 MBH

60 = 2700 - 20000 MBH

70 = 2900-29000 MBH

Capacity Range - There are one or more for each

burner size. The number will be 0, 1, or 2 in increas-

ing size. The letter will be A, D, or E and indicates the

mixing case size. This will, of course, affect the firing

range of the burner.

SECTION 24 – BURNER INSTALLATION (WEISHAUPT BURNERS)

For all European direct-fired unit shipments re quir-

ing 50 Hz CE code wiring, Johnson Controls sup plies

a Weishaupt burn er in lieu of a Power Flame burner.

Johnson Controls can also supply a Weishaupt burner

as a special order for any USA unit shipment.

Weishaupt burners are easily distinguished by their

bright red color. Basically, the Weishaupt burners op-

erate in the same manner as the Power Flame burners.

Some of the main differences are:

1. A backdraft damper is not required for operation

and is not part of the absorption unit’s ship loose

parts. Weishaupt burners are able to operate in a

back-pressure be tween -1.0 inch of water column

through 6 inches of wa ter column and even high-

er pressures with some burner mod els.

2. The modulating gas buttery valve (normally

found on the gas train for Power Flame burn-

ers) is an in te gral part of the Weishaupt burn-

er, mounted directly on the burner hous ing. The

buttery valve is spring loaded to fully close the

valve, if the drive linkage is disconnected.

3. Capacity regulation is controlled by a single ser-

vo mo tor, equipped with individual adjustable

micro switch es. This servomotor is integrally

linked to the gas buttery valve and combustion

air control louvers via a single cam arrangement.

Therefore, the Varicam, jackshafts, and linkage

sets normally found on the Pow er Flame burners

are not present on the Weishaupt burners.

4. All Weishaupt burners have a cast aluminum

burner housing that is hinged for ease of service.

Because of this design, no pedestal support is

needed for the Weishaupt burner.

5. Weishaupt includes a burner-mounted oil pump

for burn ers siz es 30, 40, and 50 that use #2 fuel

oil. There fore, there is no oil pump or mo tor in

the unit’s ship loose parts.

As with the Power Flame burners, the Weishaupt burn-

ers are mounted at the Johnson Controls factory and

the burner is pre-wired into a unit mounted burner pan-

el - if the unit is not a knockdown shipment. The gas

train components will be shipped sep a rate ly and will

re quire field mount ing.

MODEL IDENTIFICATION

The following is an example of a Weishaupt burner

designation:

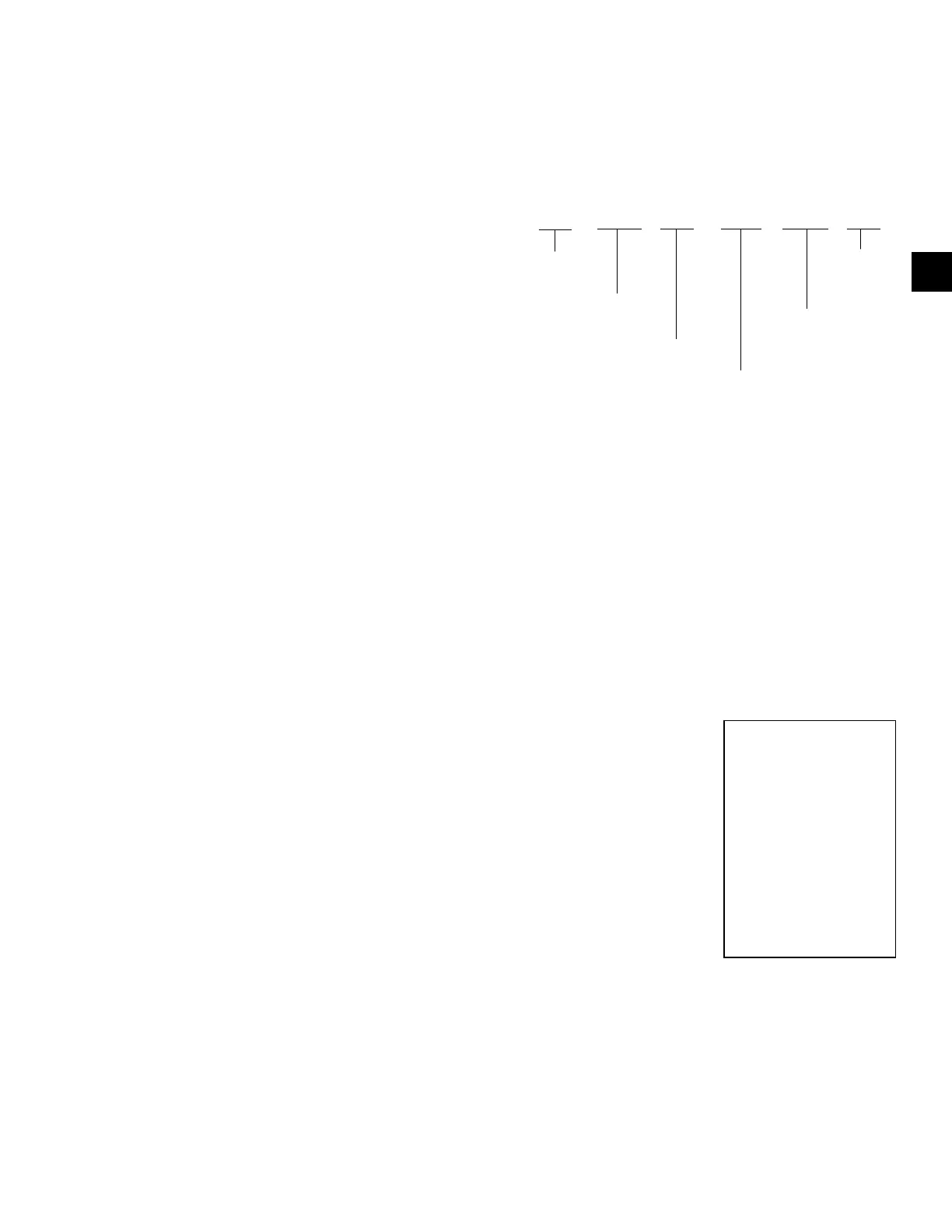

R GL 40 / 1-D ZM D

,

Operation

Fuel Types

Burner Size

Regulation

Type

Electrical

Power

Supply

Capacity

Range

MBH values are

ap prox i mate. If burner

system has Flue Gas

Recirculation (FGR),

reduce MBH by 10%.

If sys tem has Ox y gen

trim, de duct 15%. If

sys tem has FGR and

Ox y gen trim, de duct

25% from the rated

burner capacity.

Loading...

Loading...