JOHNSON CONTROLS

21

FORM 155.17-N1

ISSUE DATE: 4/1/2013

5

SECTION 5 – LEVELING THE UNIT

The YORK ParaFlow

TM

Chiller/Heater will operate

prop er ly and produce maximum output only if it is

installed level. Therefore, it is important that the unit

be leveled when installed in place, and checked again

(and adjusted if necessary) after the piping, solution,

refrigerant and system water have been installed.

G-style units are provided with punch-marked lev el-

ing lines and an indicating sticker at each level line on

the tube sheets. See photo in Figure 4 on page 21.

Use these lines as ref er ence points when lev el ing the

unit. Do not use the bot tom of the tube sheet or any

part of the indicating sticker.

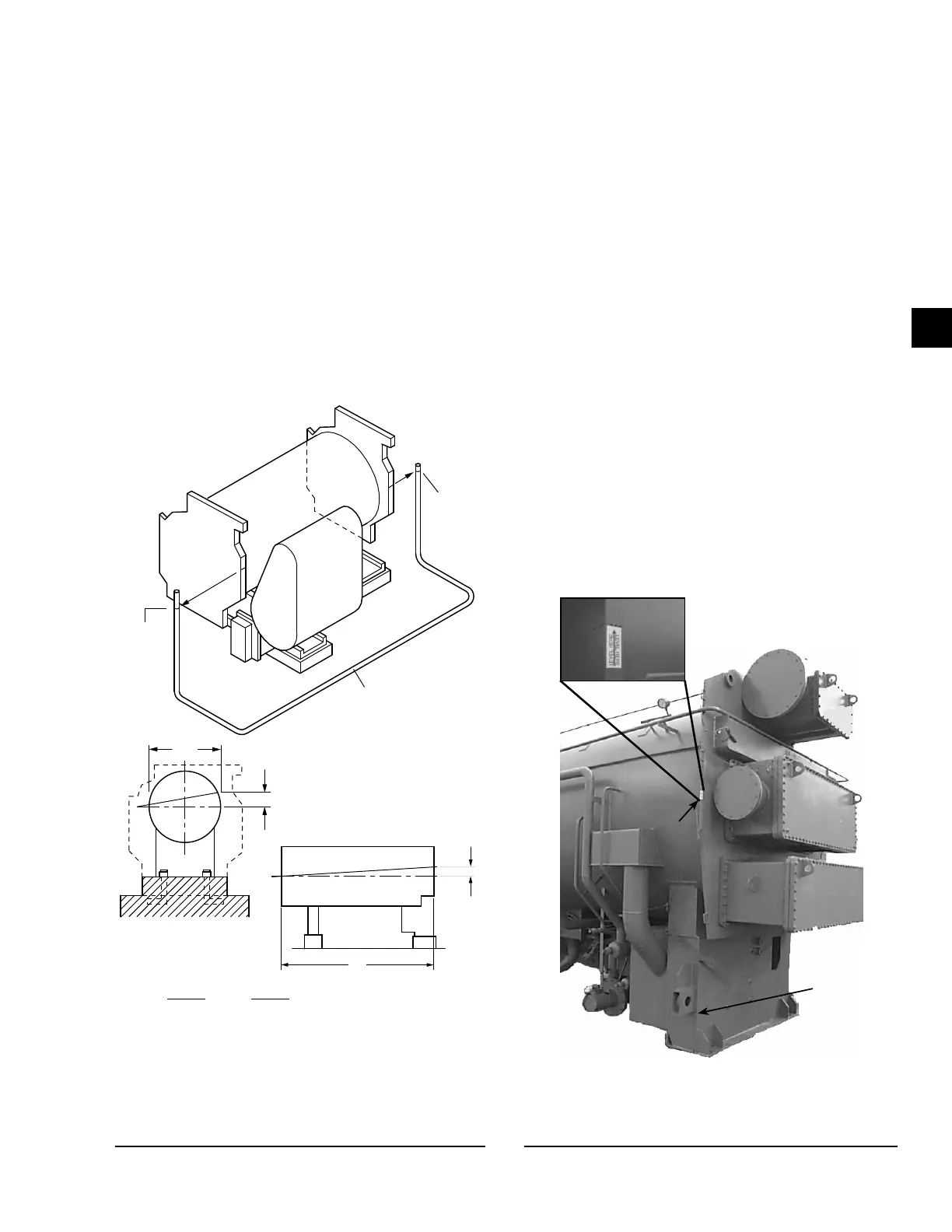

FIGURE 4 - LEVELING AND ANCHORING THE

UNIT

LD05299

A

B

C

D

b

a

B

A

a

=

A

= B = b

1000 1000

MAXIMUM ALLOWABLE OUT-OF-LEVEL

TOLERANCE BETWEEN ANY TWO CORNERS

WATER

LEVEL

SEMI-TRANSPARENT

VINYL HOSE

TUBE

SHEET

WATER

LEVEL

S-style units are built on a skid and require that the

unit be level within 1 inch in 1000. S-style units also

have punch-marked and scribed level lines on the tube

sheet, which are identified by a lev el ing sticker at each

line on the chill er tube sheets.

LEVELNESS CHECK

Use a transparent or semitransparent flexible hose.

As shown in Figure 4 on page 21, check the lev-

els of points A-B, A-C, and A-D. Secure one end of

the hose to corner A with tape. Move the other end

of the hose to the opposite corner and fasten with

tape. Fill the hose with water until the wa ter lev el in

the hose cor re sponds to the unit level mark on the

tubesheet at corner A. The distance between the unit

level mark on the unit tubesheet and the water level

in the hose at the opposite end of the unit is how far

the unit is out-of-level. The unit should be lev eled

to with in 1 inch in 1000, both length wise and side-

wise (see Figure 5 on page 21). Use jacks at jack-

ing points on unit legs to raise and low er unit during

lev el ing.

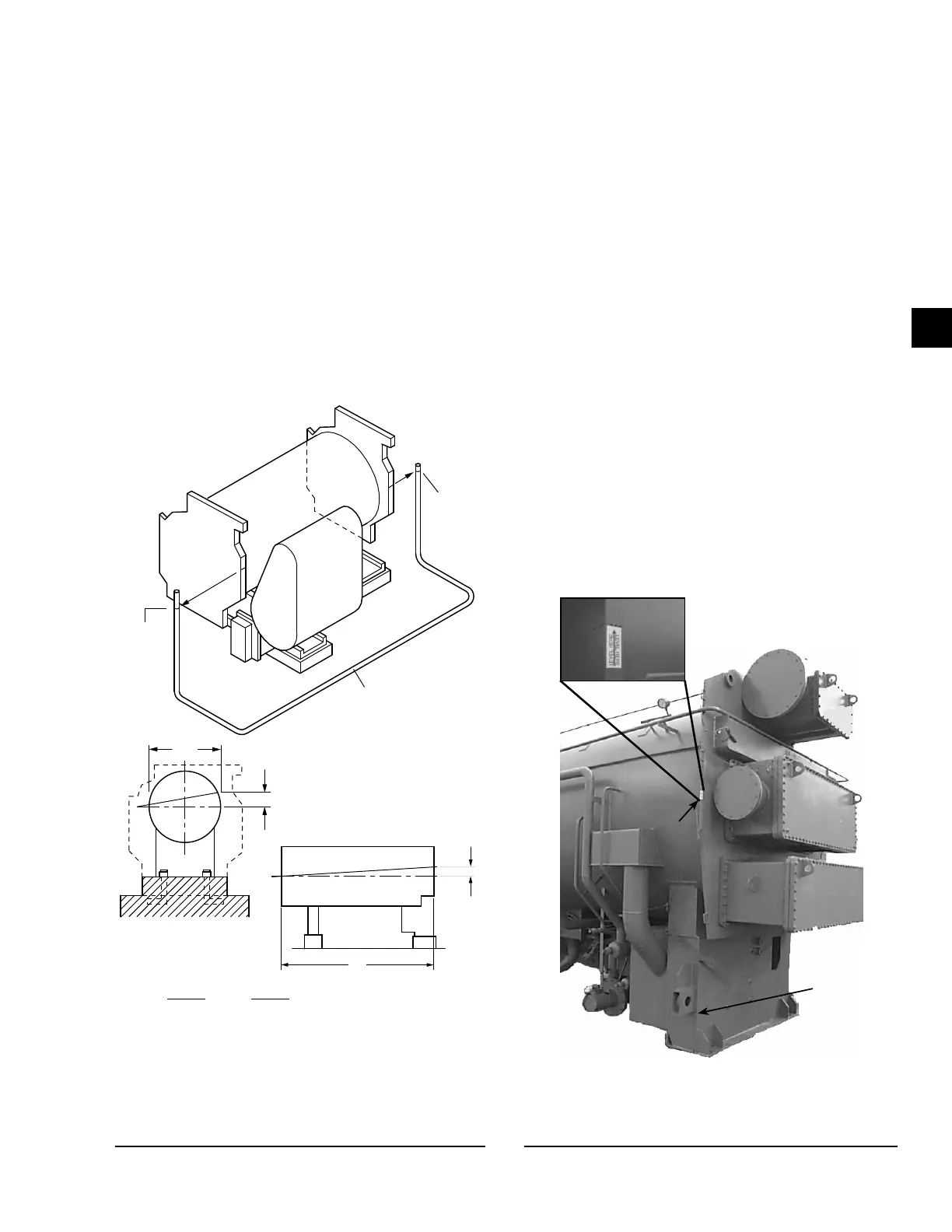

00296VIP

Level Marker

Jacking

Point

FIGURE 5 - JACKING POINT

00294VIP

Loading...

Loading...