JOHNSON CONTROLS

47

FORM 155.17-N1

ISSUE DATE: 4/1/2013

14

Prior to designing/installing oil pip ing

systems, all national, local and other

applicable codes, restrictions, and reg-

u la tions should re viewed to ensure to tal

compliance.

ParaFlow

TM

Units are designed for use with #2 fuel oil.

A two-pipe system (separate suction and return line)

must always be used. The oil pumps are preset at the

Power Flame factory with a two pipe system. The

pump war ran ty will be voided if a one pipe system

is installed.

Do not install manual valves in the return line between

the pump and the oil tank unless required by a specific

code. If a manual valve is required, an automatic relief

valve must be installed across the manual valve to en-

sure that oil will bypass directly back to the tank in

the event the manual valve is inadvertently left in the

closed position. It is always best to keep the oil return

SECTION 14 – OIL PIPING DESIGN

line at the same level or lower than the oil pump. Ex-

cess back pressure may damage the oil pump.

Do not use Teflon tape on any oil piping connec-

tions. Rigid pipe connected to the pump may cause ex-

cessive vibration. It is recommended that the connec-

tion to the pump be of copper tubing, complete with

a vibration damp en ing loop, on both the suction and

return lines. Copper tubing with flare fittings or iron

pipe is to be used on all installations. All units must

utilize the proper size and type of suction line oil fil-

ters. See Table 10 on page 90 in Appendix A at the

back of this document for prop er oil filter usage.

Some burners, even though they are strictly oil burn-

ers, re quire a gas flame ignitor pilot be used instead

of elec trode flame ignition. Usually any Power Flame

burner larger than a CR4-(G)O-25, or a burner that has

an oil us age ca pac i ty of greater than 60 gpm, requires

that a gas pilot be used.

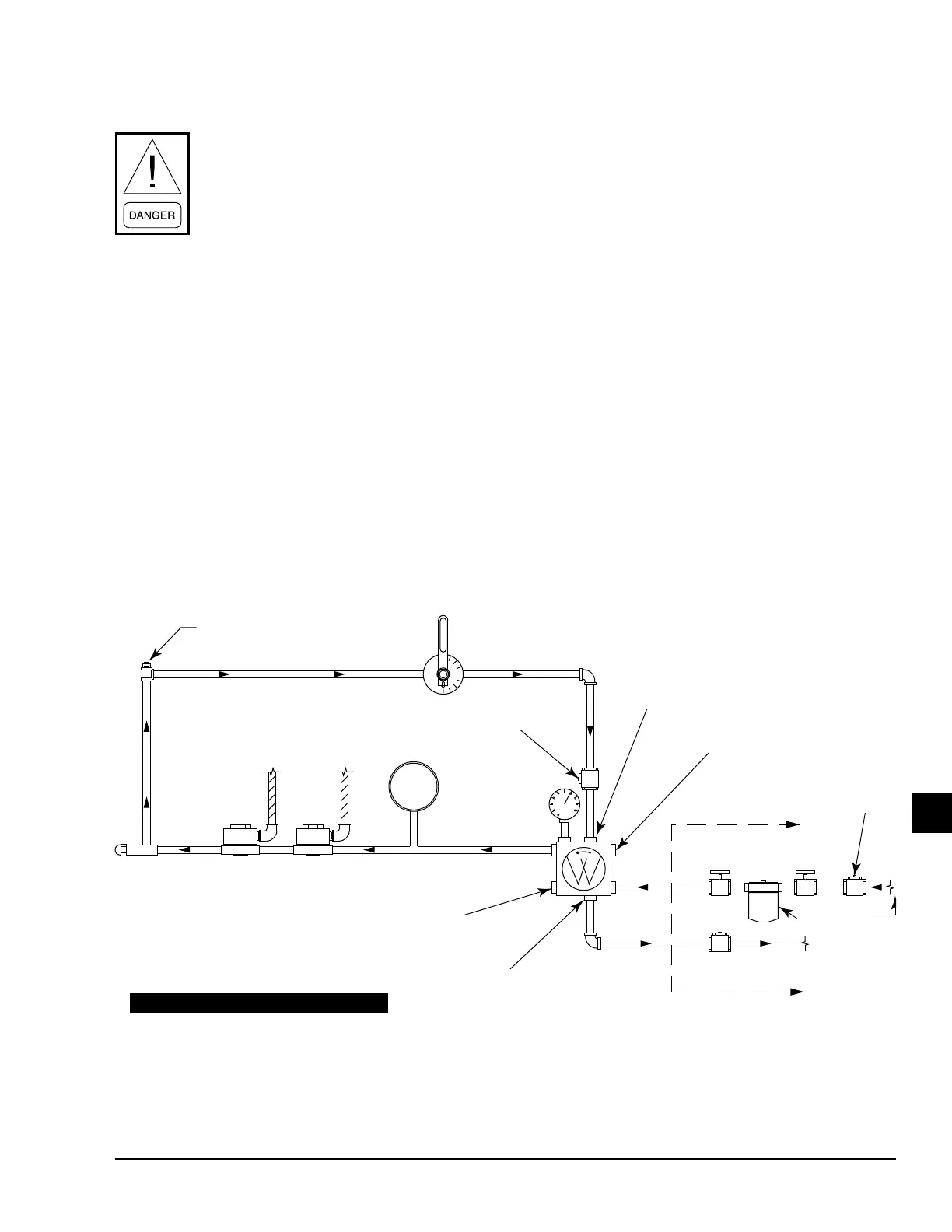

FIGURE 22 - TYPICAL SCHEMATIC OIL PIPING

LD05311

RETURN PRESSURE TRAP

NOZZLE

OIL SOLENOID VALVES

OIL PUMP

VACUUM GAUGE

INLET PORT

RETURN PORT

FIELD PIPED COMPONENTS

TO BE SUPPLIED BY CUSTOMER

CHECK VALVE

FILTER

CHECK VALVE

AT TANK

FUSIBLE LINK

VALVE

SHUTOFF

VALVE

INLET PORT

METERING VALVE

GAUGE

PRESSURE

TEST PORT

LOW OIL

PRESSURE SWITCH

CHECK VALVE

OPTIONAL RETURN PORT

1/8" ALLEN SCREW UNDER CAP

SCREW FOR NOZZLE OIL

PRESSURE ADJUSTMENT

DO NOT USE TEFLON TAPE ON OIL LINES

CAUTION: ALL FIELD COMPONENTS MUST BE MOUNTED IN

THE PROPER LOCATION AND DIRECTION OF OIL FLOW.

CAUTION: OIL SUPPLY MUST NOT EXCEED 3 PSI PER NFPA CODE

OIL

SUPPLY

OIL

RETURN LINE

Loading...

Loading...