JOHNSON CONTROLS

67

22

FORM 155.17-N1

ISSUE DATE: 4/1/2013

SECTION 22 – SEQUENTIAL DRAFT CONTROL (Motorized Draft Control)

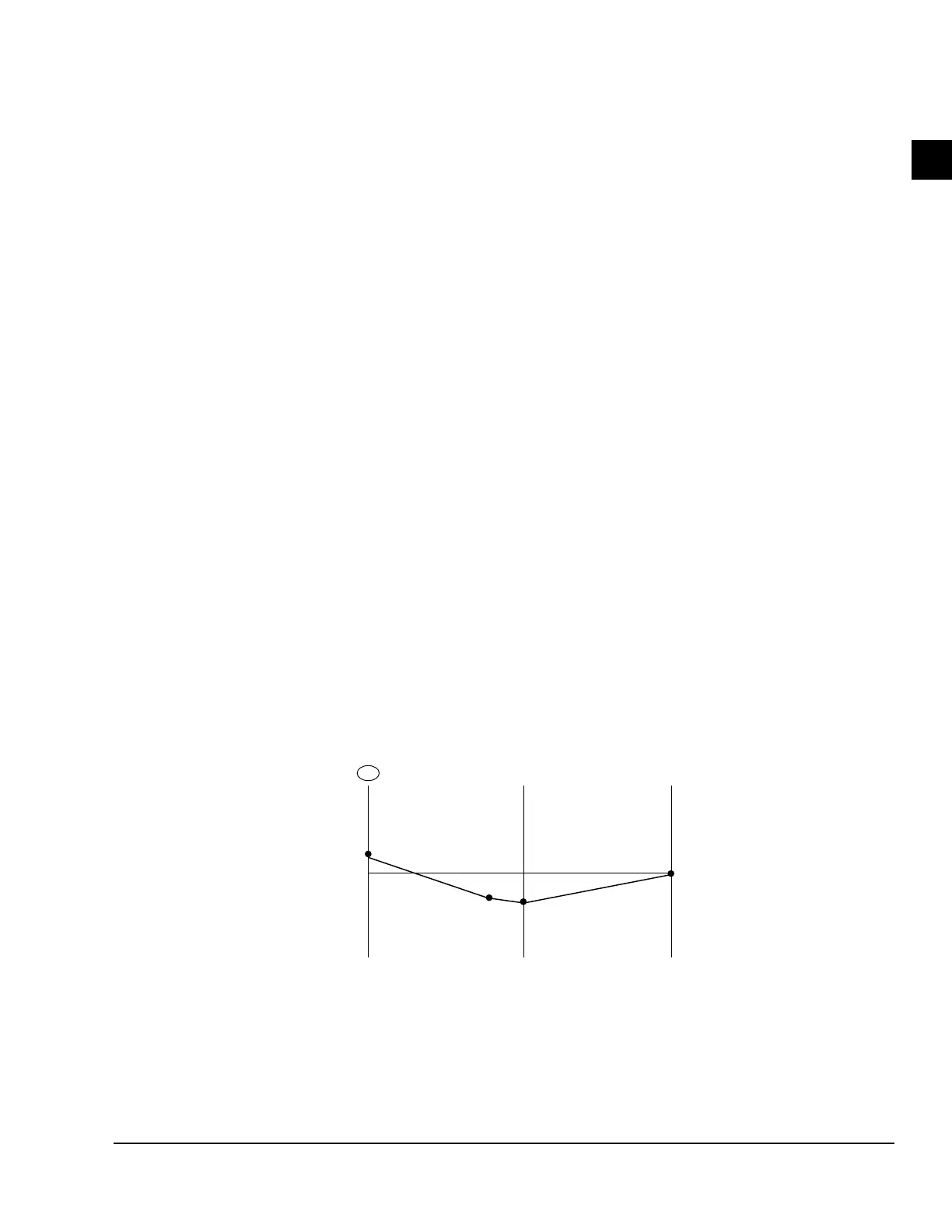

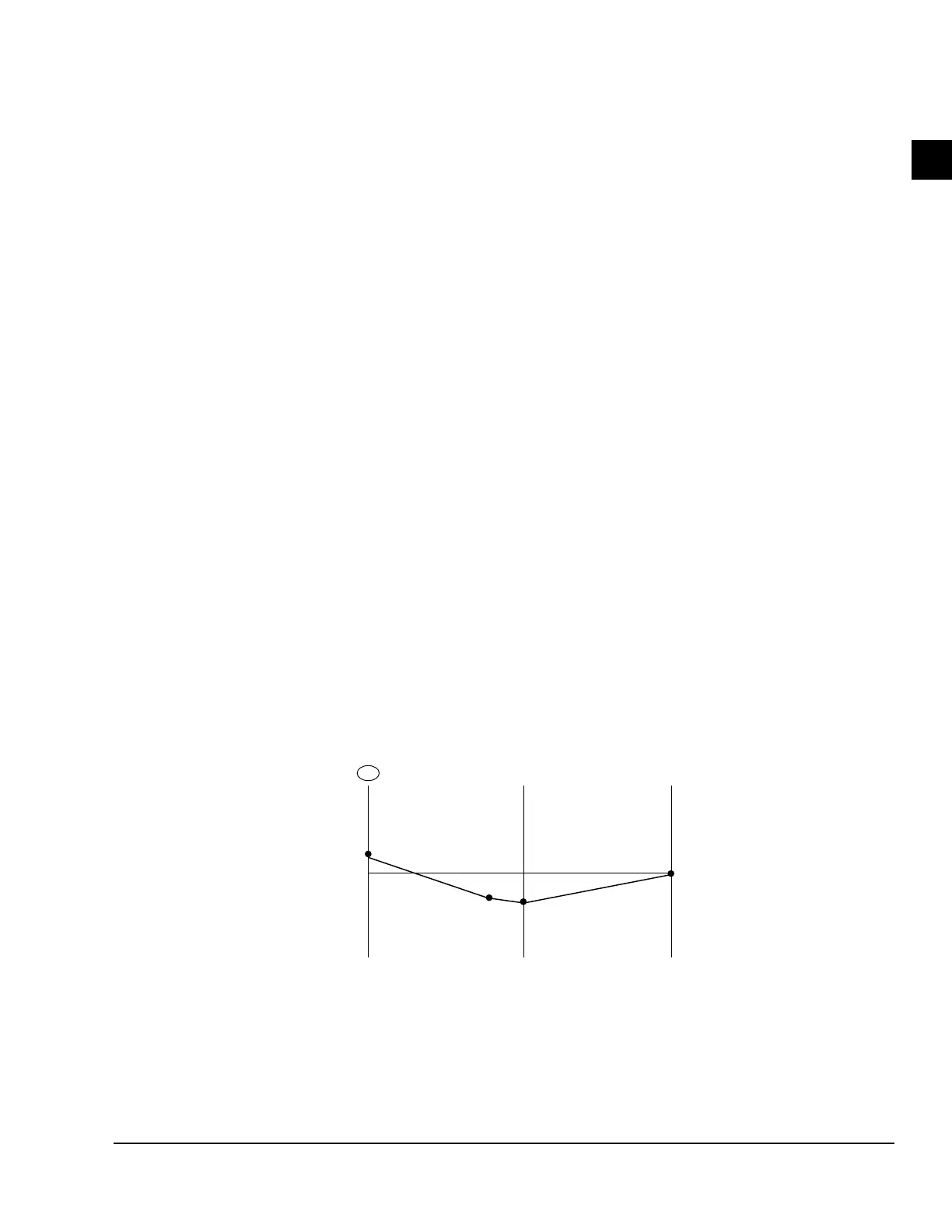

Figure 32 on page 67 and Figure 33 on page 68

depict a sequential draft control system. This type of

system incorporates an actuator motor mounted on top

of the damper assembly. The actuator arm is connected

to the damper blades through a linkage system to auto-

matically open or close the damper blades. The actua-

tor receives a signal from a separately mounted “Over-

fire Draft Control Panel” that constantly monitors the

present draft at the outlet of the first stage generator.

The signal to the actuator motor constantly adjusts the

damper blades to provide the available draft required

per burner loading.

Motorized draft control is suitable for ap pli ca tions

where multiple gas-fired appliances will be ducted into

one com mon chimney system. In this case, each unit

will require its own draft control system. (Motorized

draft control may be used for one unit/one chimney

ap pli ca tions, if desired, over the standard barometric

damper control).

When multiple ParaFlowTM Chiller-Heaters are to be

duct ed into a common breeching or chimney system, it

is recommended that separate draft control system be

pro vid ed for each unit.

BACKDRAFT DAMPER

The Johnson Controls supplied manual backdraft

damper can be modified (in the factory if ordered, or

in the field) to mount the motor driver. The motor is

controlled from a draft control panel which senses the

pressure at the out let of the high-temperature genera-

tor. The draft control panel is available from Johnson

Controls to ship with the chiller (see Figure 29 on

page 63 for drawing of the motorized damper). The

pan el is wired to the burn er panel and damp er motor

in the field, and the pres sure is sensed through a small

line field-con nect ed to the outlet of the chiller-heat er.

Not recommended to mount vertically

reasons:

1. Not best position for optium draft (See Figure 32

on page 67)

2. Creates more area for positive pressure. could

leak combustables into equipment room.

3. More difcult to control combution chamber

pressure.

A

B

C

D

TOP OF

CHIMNEY

SYSTEM

BASE OF

VERTICAL

CHILLER-HEATER

OUTLET

1

GAUGE

PRESSURE

(IN. WATER)

0

+

–

Point B is downstream

of motorized damper

FIGURE 32 - GAUGE PRESSURE PROFILE / CHIMNEY SYSTEM WITH SEQUENTIAL DRAFT CONTROL

LD05357

NOTES:

1. dP between A and B due to transition piece and motorized damper. Damper automatically controls to maintain of water at A. The actual

dP is variable and depends on the momentary gauge pressure C.

2. Maximum draft (minimum gauge pressure) occurs at base of vertical section of chimney (C). With sequential draft control, this valve is

allowed to drift with prevailing ambient conditions. Motorized damper controls to maintain steady gauge pressure at A.

Loading...

Loading...