JOHNSON CONTROLS

26

SECTION 6 – UNIT WATER PIPING AND HOOK-UP

FORM 155.17-N1

ISSUE DATE: 4/1/2013

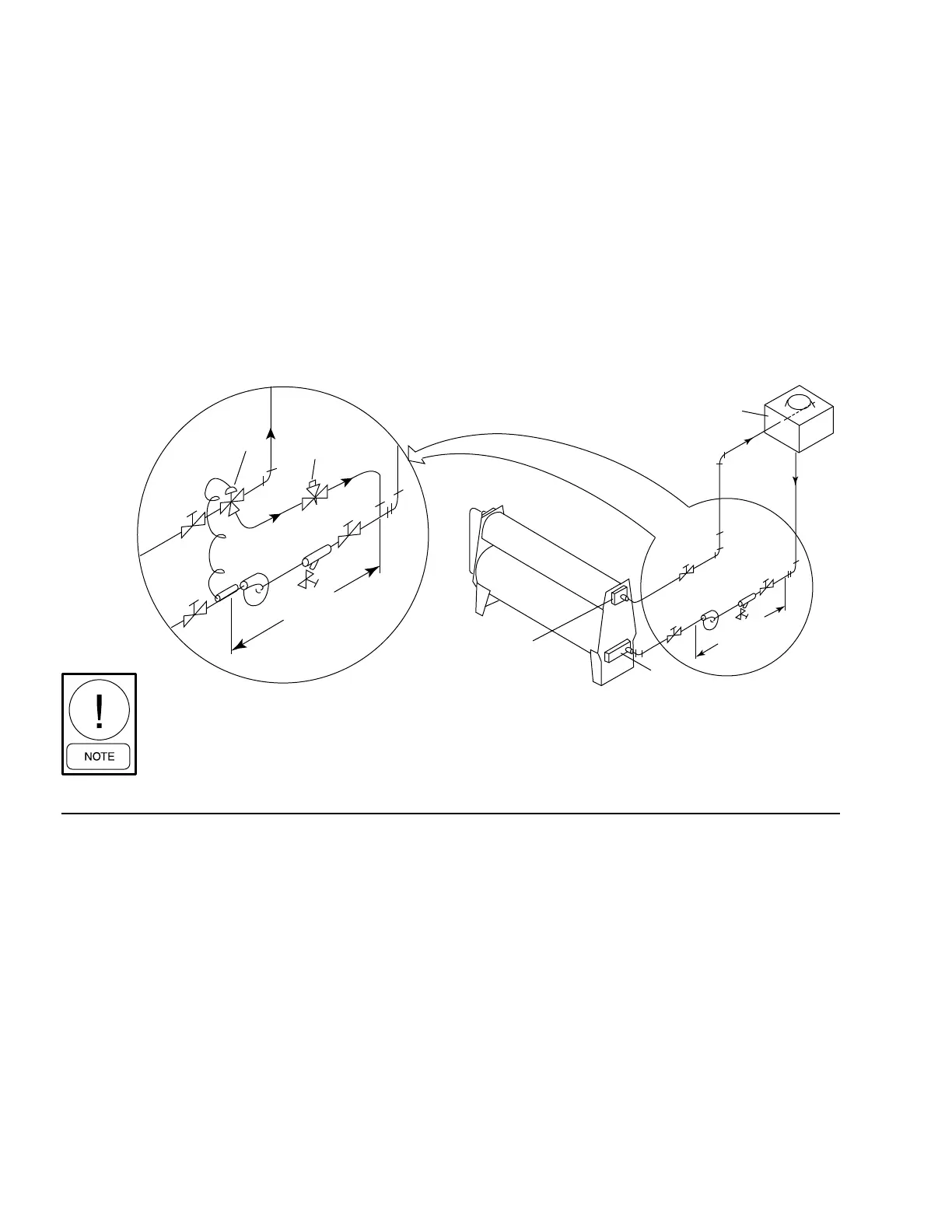

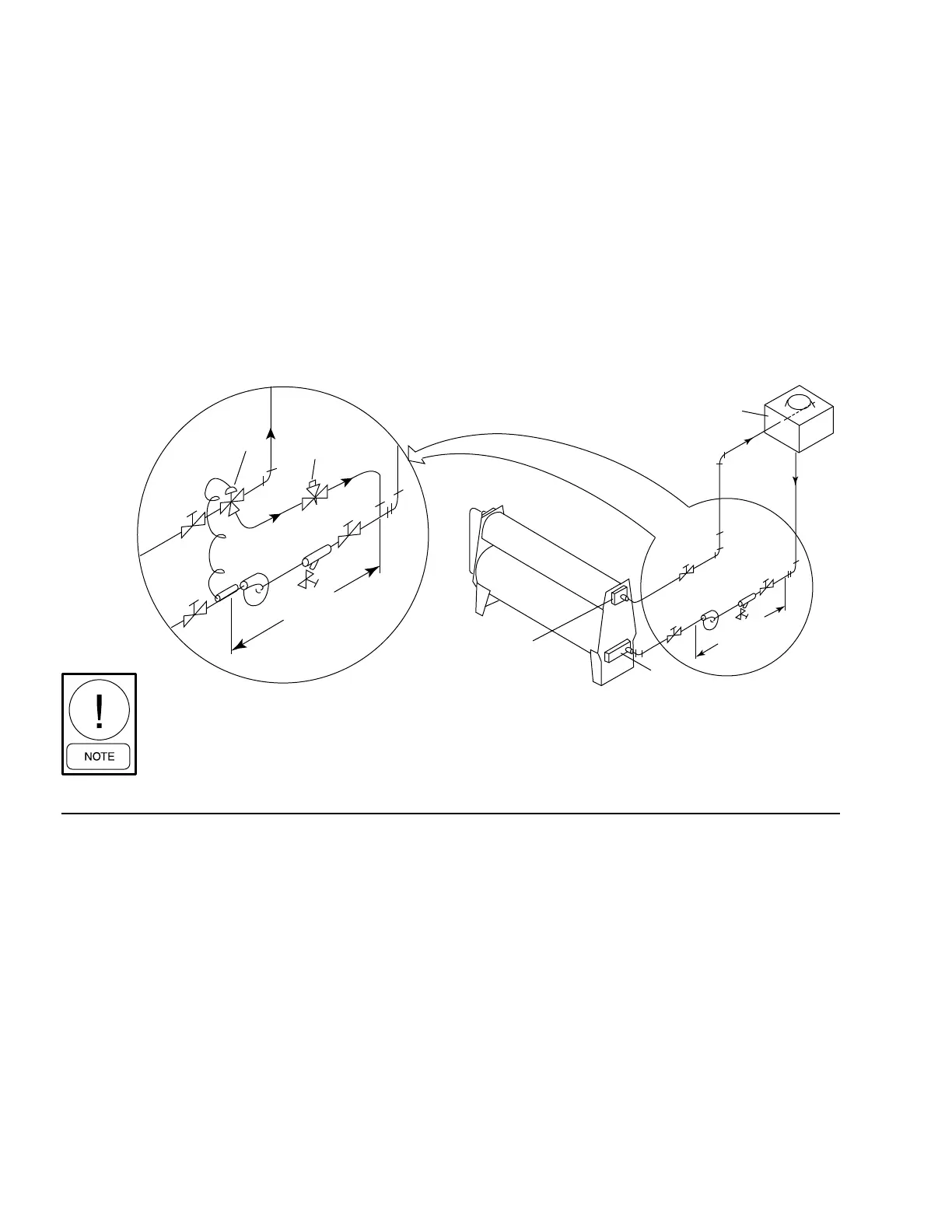

THREE-WAY MIXING VALVE

The temperature of the tow er water to the absorber

shell of the unit must be main tained at all times be-

tween 68°F, (20°C) and the design tem per a ture of the

unit [typically 85°F, (29.4°C)]. How ev er, at unit start-

up, the tower water may be as low as 59°F, (15°C)

providing the water temperature reaches 68°F, (20°C)

in a 30 minute period. The tower water must not

change in temperature more than 0.5°F (0.28°C)

per minute.

A three-way mixing valve (or tower bypass valve)

with ac com pa ny ing temperature controller, as in di cat-

ed in the Unit Water Piping and Hook-Up section of

this doc u ment, is recommended to con trol tow er wa ter

tem per a ture. This valve could be installed at either the

inlet side (di vert ing flow) or outlet side (mixing flow)

of the cool ing tower. The sizing of this valve is crit i cal

and should be left up to the build ing pip ing en gi neer to

prop er ly size the valve so that de sign chill er flow can

be maintained under all op er at ing con di tions. Detail of

a 3-way mixing valve is shown in Figure 10 on page

26.

DETAIL A

CONDENSER

ABSORBER

D

10' MAX.

COOLING TOWER

B

C

D

10' MAX.

Before

commissioning the ParaFlowTM Chiller/Heater,

all unit system water piping must be leak checked and flushed.

All water strainers must be cleaned after flushing and trapped air vented.

PIPING USING

A TOWER

BYPASS

VALVE

SQUARE HEAD

PLUG COCK

3-WAY

CONTROL

VALVE

FIGURE 10 - PIPING FOR TOWER WATER - THREE-WAY MIXING VALVE

ld05846

Loading...

Loading...