JOHNSON CONTROLS

40

SECTION 12 – BURNER INSTALLATION (POWER FLAME BURNERS)

FORM 155.17-N1

ISSUE DATE: 4/1/2013

unit in spec tion. If it has, disregard this step and contin-

ue. Components that were not mount ed on the burn er

(ship loose) are des ig nat ed with an “L” on the sheets.

Claims of dam age to the burn er or shortage must be

im me di ate ly filed with the carrier. Support the burn er

with the Power Flame sup plied pedestal. Cut the ship-

ping tie-wraps from the U-bolt af ter the burn er is well

supported by the pedestal.

The following pages show the typical arrangements

and components of the burner and gas trains. Gas units

will have similar components, however, all oil compo-

nents shown will not be present. For specifics on your

system, refer to the technical information supplied with

the burner.

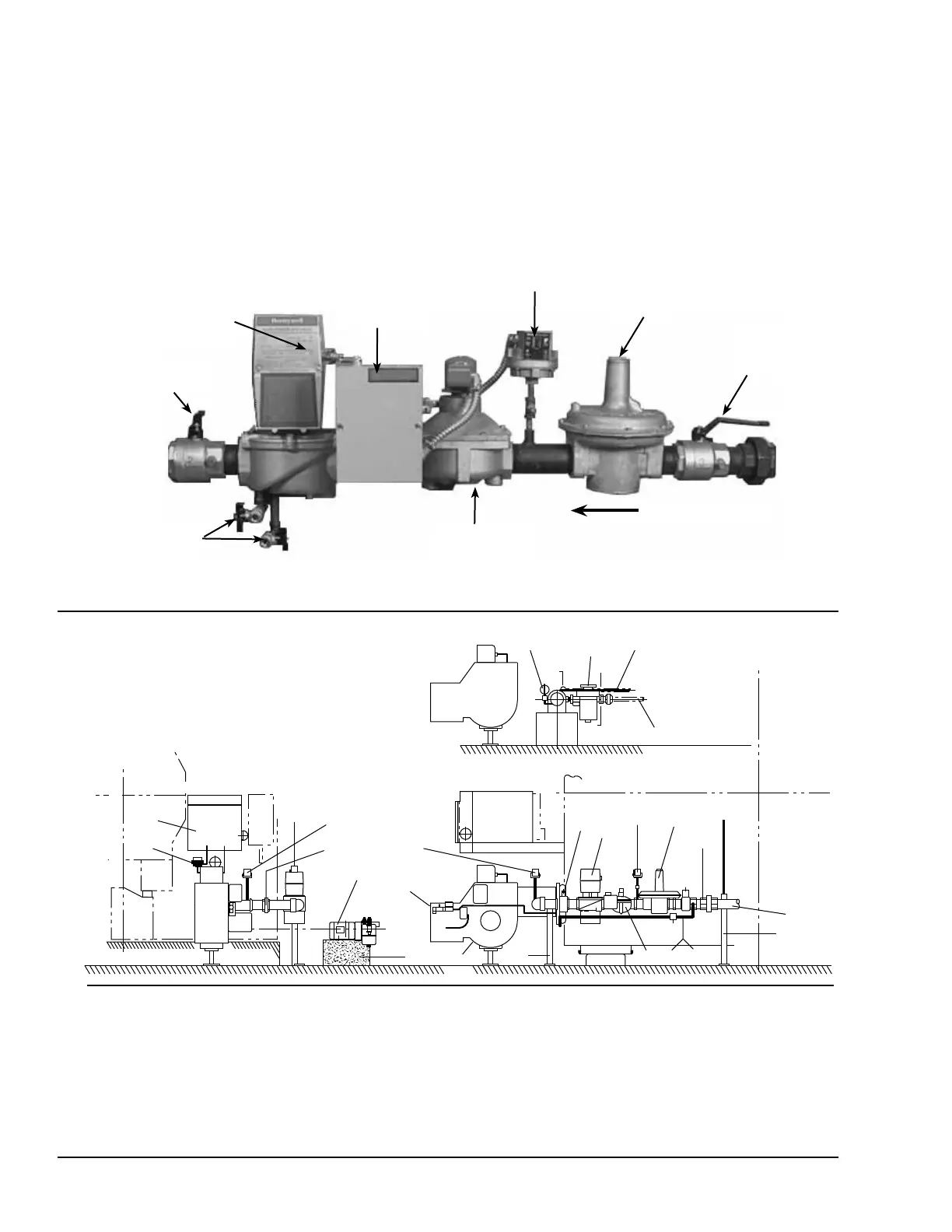

FIGURE 13 - TYPICAL GAS TRAIN COMPONENTS

00268VIP

Main Manual

Gas Shut-off

Cock

Main Gas

Pressure

Regulator

Low Gas Pressure

Switch

Redundant Main

Gas Solenoid

Valve

Gas Train Junc-

tion Box

Main Gas Valve

w/ Proof of Clo-

sure Switch

Manual Gas Check-

ing Cock

Gas Valve Leak

Test Valves

Flow Direction

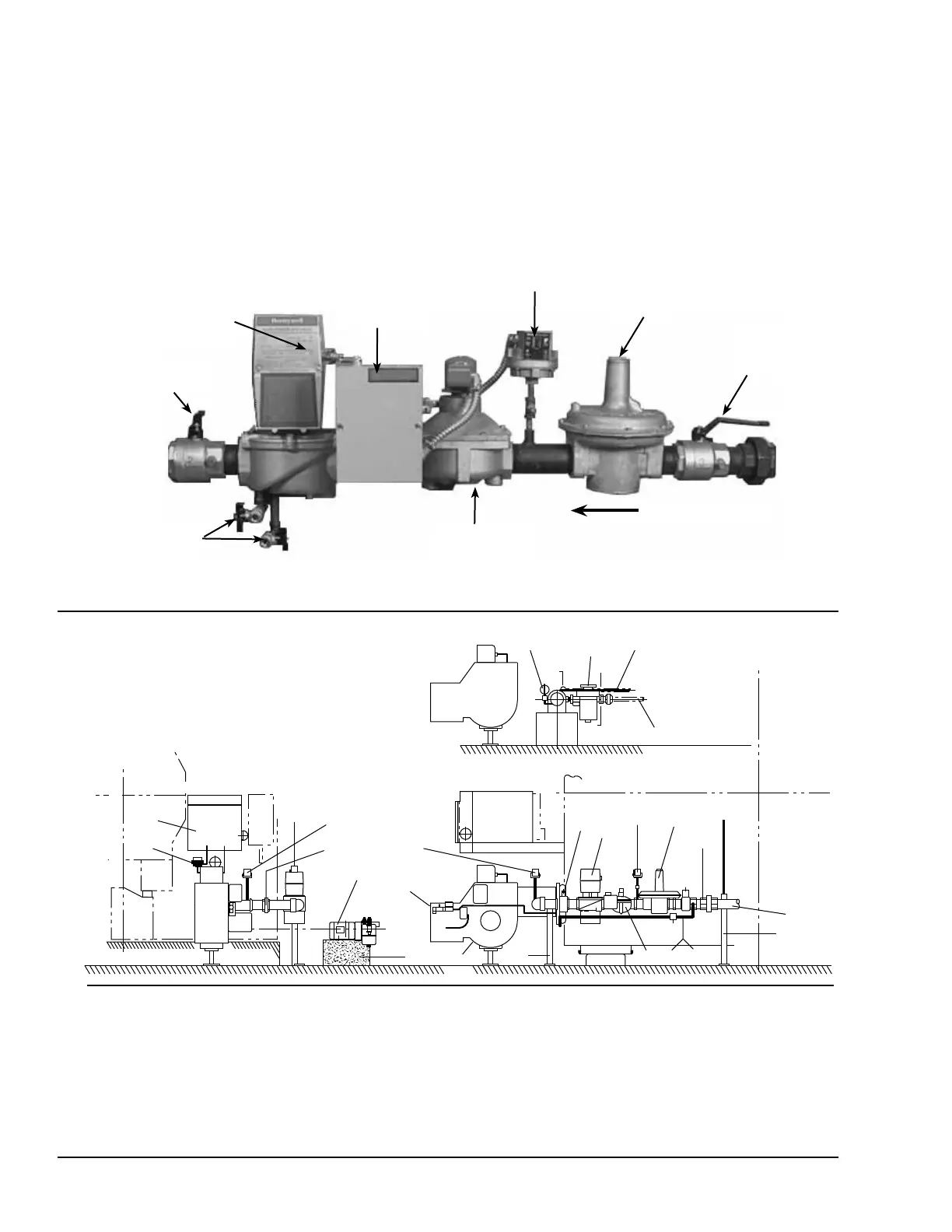

FIGURE 14 - TYPICAL BURNER ASSEMBLY FOR DIRECT-FIRED, S-MODEL UNITS

LD05307

ITEM NAME

01 Base (For Oil Pump Unit)

02 Support (For Oil Pump)

03 Gas Supply Piping

04 Oil Supply Piping

05 Oil Return Piping

06 Union

07 Main Gas Shut-O Cock

ITEM NAME

08 Main Gas Pressure Regulator

09 Low Gas Pressure Switch

10 Auxiliary Gas Valve

11 Pilot Regulator

12 Main Gas Shut-O Valve

13 Manual Leak Test Shut-O Valve

14 Gas Pressure Gauge

ITEM NAME

15 High Gas Pressure Switch

16 Manual Gas Shut-O Valve

17 Oil Pump Unit

18 Oil Filter

19 Oil Compound Gauge

20 Burner Unit

21 Burner Control Panel

SHELL CENTER LINE

SHELL CENTER LINE

SHELL CENTER LINE

SHELL CENTER LINE

NOTE: SOME OF THE EQUIPMENT LISTED

MAY NOT BE APPLICABLE TO ALL INSTALLATIONS

OIL RETURN

OIL SUPPLY

16 6

10

YORK

YORK

YORK

19

18

5

4

21

11

15

17

6

1

15

14

20

2

13

12

9

8

6

Loading...

Loading...