03.09 EN

84

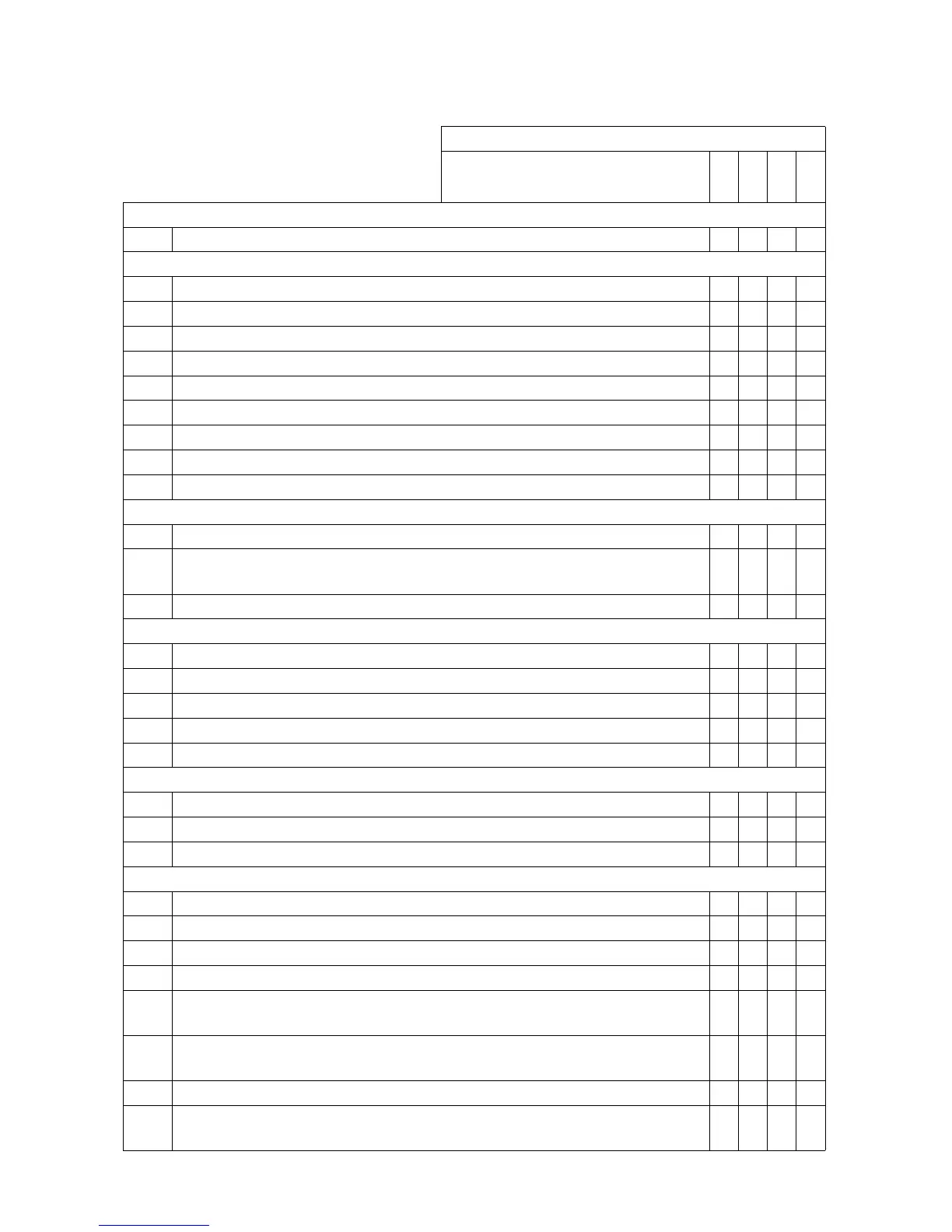

4 Maintenance checklist

Maintenance Intervals

Standard = t

Cold store = k

WAB C

Braking

1.1 Check magnetic brake air gap t

Electrical system

2.1 Test instruments, displays and control switches. t

2.2 Test warning and safety devices kt

2.3 Check fuse ratings. t

2.4 Make sure wire connections are secure and check for damage. t

2.5 Test micro switch settings t

2.6 Check contactors and relays t

2.7 Safety switch t

2.8 Test cable and motor attachments t

2.9 Check carbon brush wear, replace if necessary kt

Power supply

3.1 Visually inspect battery kt

3.2

Check battery cable connections are secure, grease terminals if nec-

essary

kt

3.3 Check acid density, acid level and battery voltage kt

Travel

4.1 Check the transmission for noise and leakage t

4.2 Replace gear oil if service life exceeded (10000 hours)

4.3 Check rail guide roller bedding and attachment t

4.4 Check wheels (load wheels / drive wheel) for wear and damage kt

4.5 Check wheel suspension and attachment. t

Chassis and superstructure

5.1 Test the operator platform and check for damage t

5.2 Check chassis and screw connections for damage t

5.3 Check labels t

Hydraulic operation

6.1 Visually inspect rollers, slide pieces and stops. t

6.2 Check operation, wear and setting. t

6.3 Test hydraulic system. kt

6.4 Check the hydraulic auxiliary unit (not on EKS 110 LG). t

6.5

Check that hose and pipe lines and their connections are secure,

check for leaks and damage.

kt

6.6

Check cylinders and piston rods for damage and leaks, and make

sure they are secure.

kt

6.7 Check hydraulic oil level. kt

6.8

Replace hydraulic oil. (This may have to be performed via a special-

ist environmental service truck)

kt

03.09 EN

84

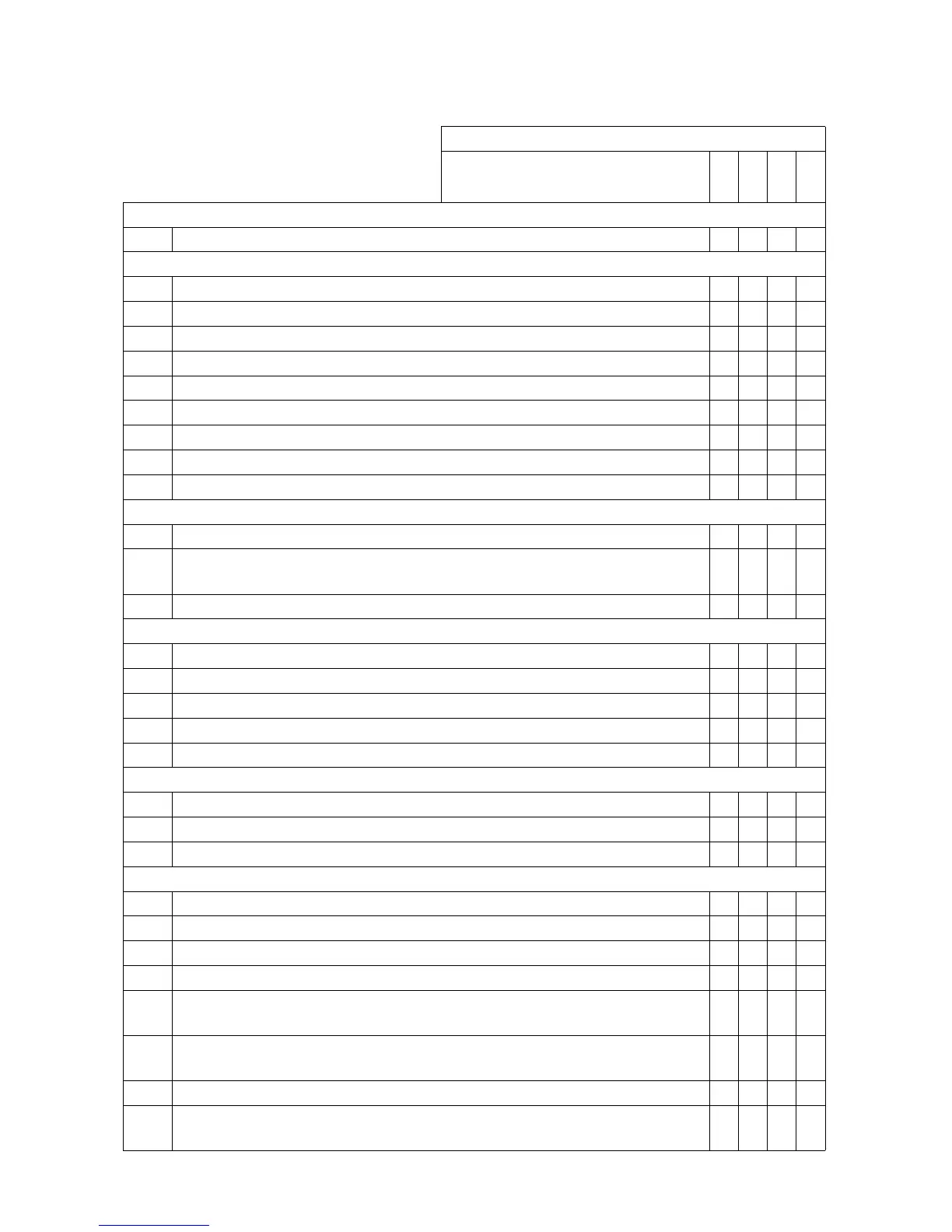

4 Maintenance checklist

Maintenance Intervals

Standard = t

Cold store = k

WAB C

Braking

1.1 Check magnetic brake air gap t

Electrical system

2.1 Test instruments, displays and control switches. t

2.2 Test warning and safety devices kt

2.3 Check fuse ratings. t

2.4 Make sure wire connections are secure and check for damage. t

2.5 Test micro switch settings t

2.6 Check contactors and relays t

2.7 Safety switch t

2.8 Test cable and motor attachments t

2.9 Check carbon brush wear, replace if necessary kt

Power supply

3.1 Visually inspect battery kt

3.2

Check battery cable connections are secure, grease terminals if nec-

essary

kt

3.3 Check acid density, acid level and battery voltage kt

Travel

4.1 Check the transmission for noise and leakage t

4.2 Replace gear oil if service life exceeded (10000 hours)

4.3 Check rail guide roller bedding and attachment t

4.4 Check wheels (load wheels / drive wheel) for wear and damage kt

4.5 Check wheel suspension and attachment. t

Chassis and superstructure

5.1 Test the operator platform and check for damage t

5.2 Check chassis and screw connections for damage t

5.3 Check labels t

Hydraulic operation

6.1 Visually inspect rollers, slide pieces and stops. t

6.2 Check operation, wear and setting. t

6.3 Test hydraulic system. kt

6.4 Check the hydraulic auxiliary unit (not on EKS 110 LG). t

6.5

Check that hose and pipe lines and their connections are secure,

check for leaks and damage.

kt

6.6

Check cylinders and piston rods for damage and leaks, and make

sure they are secure.

kt

6.7 Check hydraulic oil level. kt

6.8

Replace hydraulic oil. (This may have to be performed via a special-

ist environmental service truck)

kt

Loading...

Loading...