08.11 EN

62

3 Preparing the Truck for Operation

3.1 Checks and operations to be performed before starting daily

operation

WARNING!

Damage and other truck or attachment (special equipment) defects can result

in accidents.

If damage or other truck or attachment (special equipment) defects are discovered

during the following checks, the truck must be taken out of service until it has been

repaired.

XReport any defects immediately to your supervisor.

XTag out and decommission a faulty lift truck.

XOnly return the truck to service when you have identified and rectified the fault.

CAUTION!

Checking the accelerator pedal

XThe accelerator pedal should only be

checked when the parking brake is

applied and the engine is idle.

Checks after daily operation

Procedure

• Visually inspect the entire truck (in particular wheels, wheel bolts and load handler)

for damage.

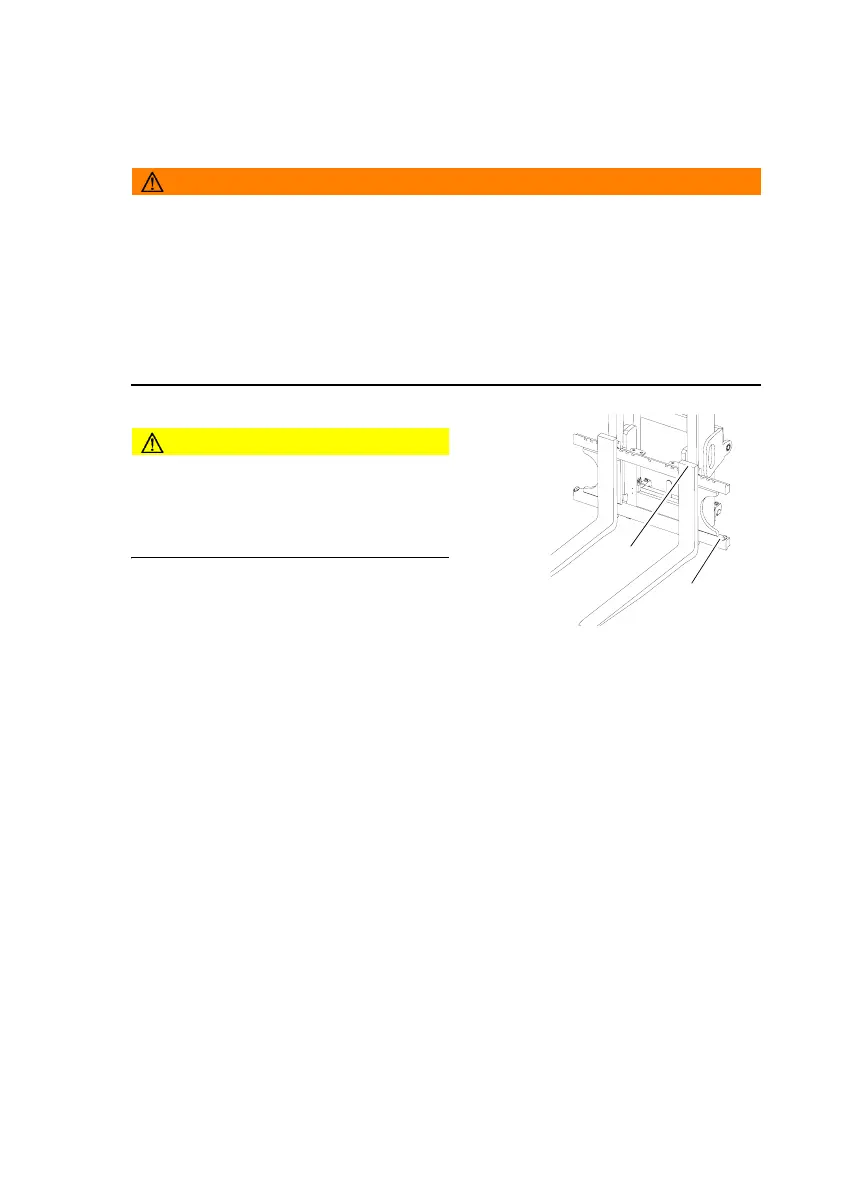

• Check the fork stop (95) and fork retainer (96).

• Visually inspect the hydraulic system in the visible area for damage and leaks.

• Check the driver’s seat has been adjusted to the correct position.

• Test the horn and reversing buzzer (o) where applicable.

• Check that the load chart and warning labels are legible.

• Test the controls and displays.

• Test the steering.

• Make sure the load chains are evenly tensioned.

• Test the seat belt. (The belt should block if extracted suddenly.)

• Test the seat switch. When the driver’s seat is vacated it should not be possible to

activate the working hydraulics.

• Test the restraint system (o),

• Test the lift/lower, tilt and if applicable the attachment hydraulic control functions.

• Check the accelerator pedal can move freely by pressing it several times.

• Test the service and parking brakes: Approach carefully and test the effectiveness

of the brake pedal.

• Check the fuel supply.

• Check the fluid level of the windscreen washing system (o), (see "Adding window

washer system fluid" on page 172).

• Check the gas system is working correctly, (see "LPG containers" on page 50)

96

95

Loading...

Loading...