4.1.2 Machine function

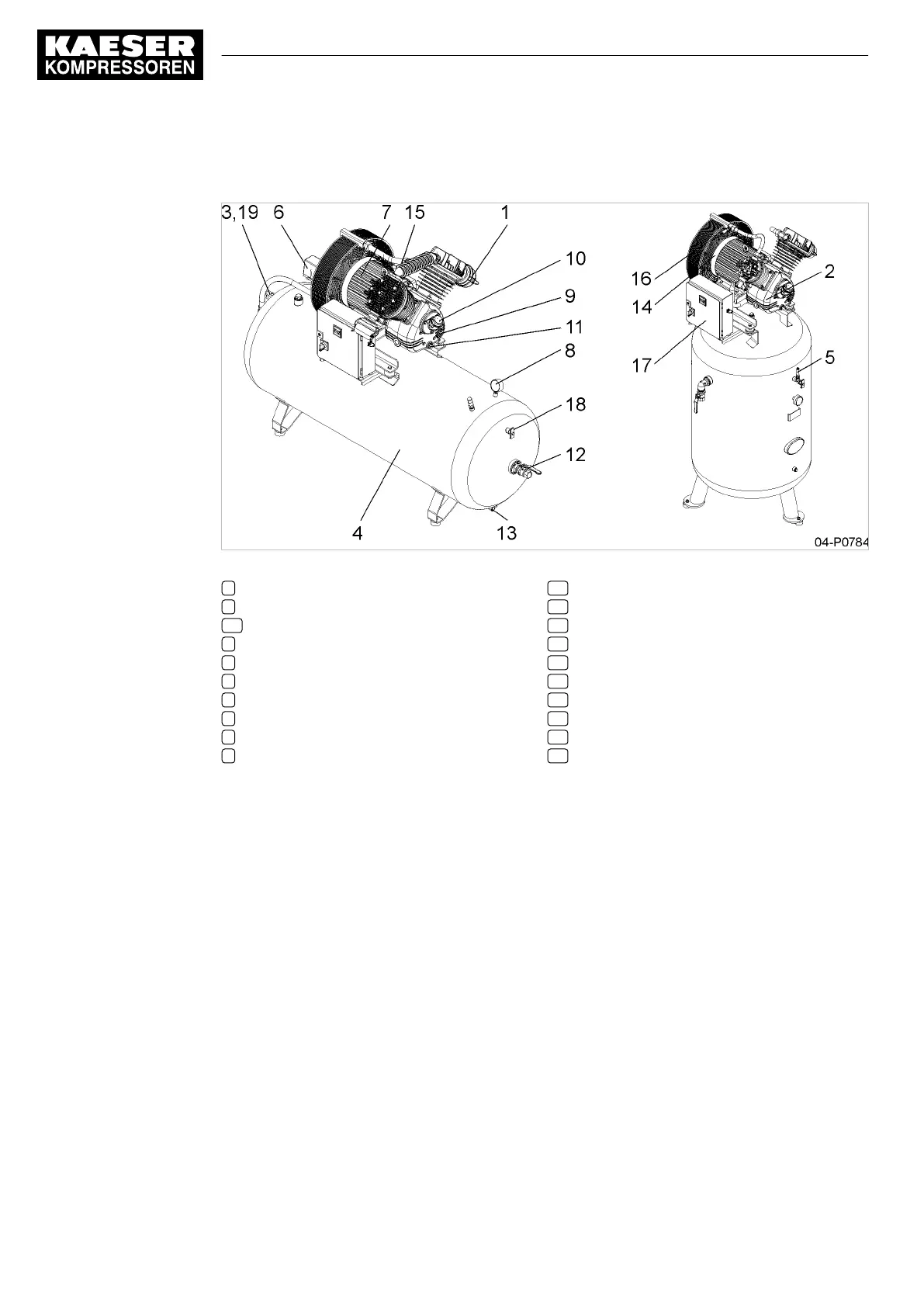

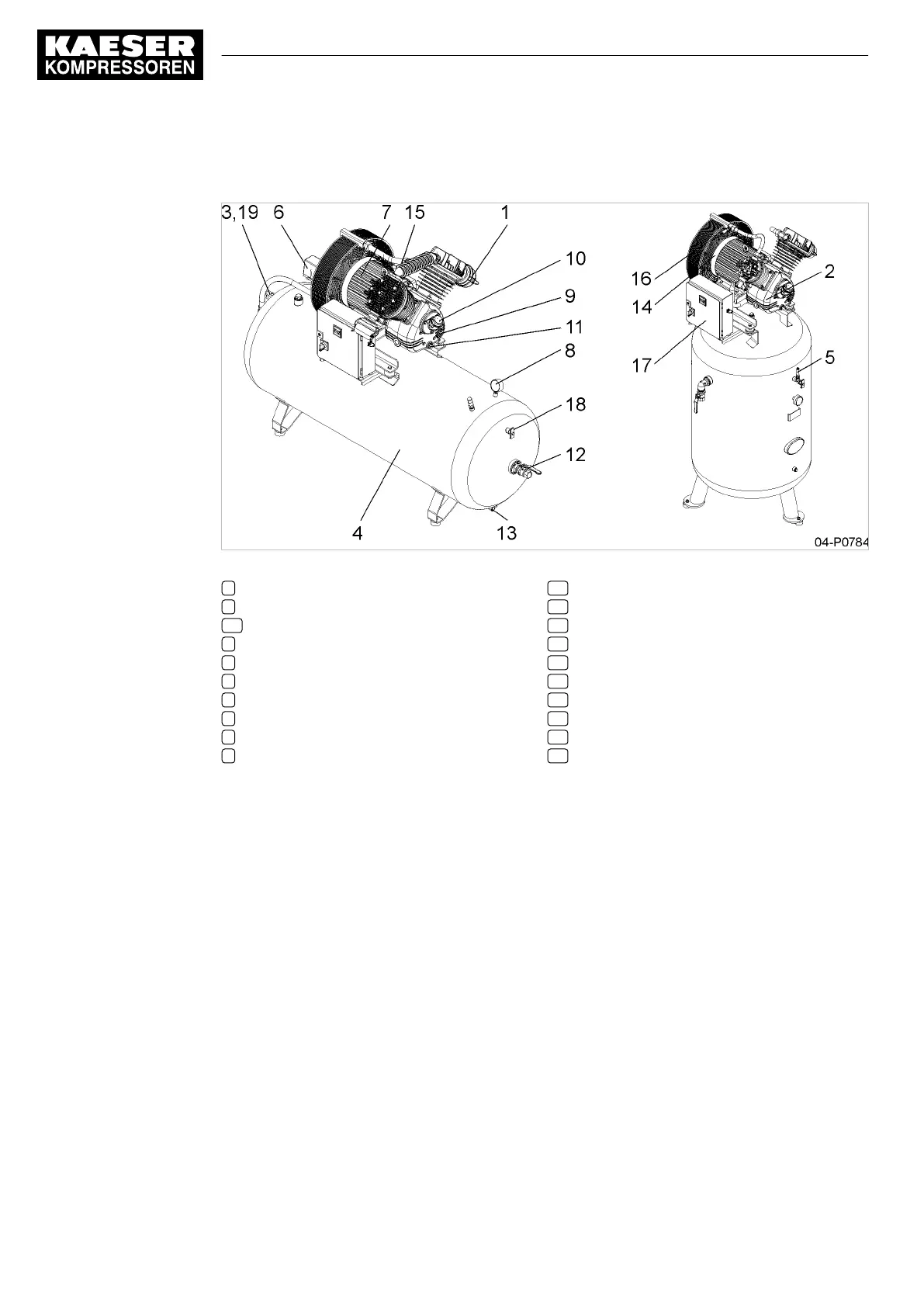

Fig. 3 Machine layout

1 Air filter

2 Compressor block

2a 2-cylinder block

3 Check valve

4 Air receiver

5 Air receiver pressure relief valve

6 Pressure switch

7 Electric motor

8 Pressure gauge

9 Oil sight glass

10 Oil filler port

11 Oil drain plug

12 Compressed air connection

13 Condensate drain tap

14 Arrow showing direction of rotation

15 Cylinder or collecting pipe relief valve

16 Air cooler

17 Star-delta starter

18 Test flange

19 Solenoid valve

Machine

Atmospheric air is drawn through a filter into the compression chamber of the block. The air is drawn

in during the downward stroke of the piston. It is compressed during the upward stroke.

The compressed air flows through the cooler, giving up most of its heat, then via the check valve into

the air receiver. The check valve prevents reverse flow of compressed air from the air receiver to the

compressor block.

4.2 Options

The options available for your machine are described below.

4.2.1 Option C5

Oil level monitoring

The oil level in the machine is monitored automatically. The machine is automatically shut down if the

oil level falls below minimum.

4 Design and Function

4.2 Options

22

Service Manual 2-stage piston compressor

EPC No.: 9_9431_02 E

Loading...

Loading...