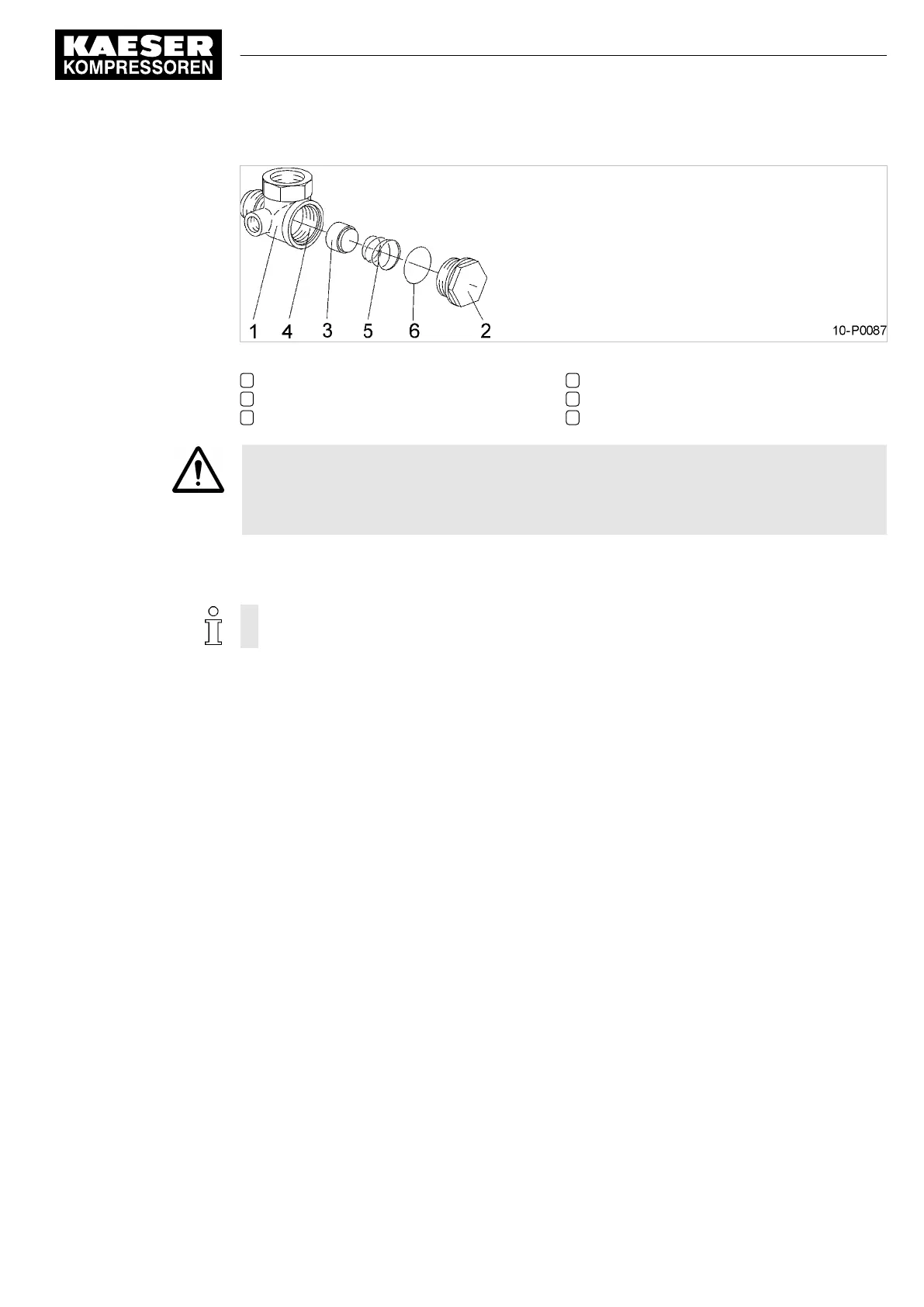

Fig. 31 Cleaning the check valve

1 Enclosure

2 Screw plug

3 Valve cone

4 Valve seat

5 Spring

6 O-ring

CAUTION

Danger of burns from hot components!

➤ Wear long-sleeved clothing and gloves.

➤ Work carefully.

1. Remove the plug.

2. Clean the valve cone and seat.

The complete valve must be replaced if the valve seat is badly worn or damaged.

3. Insert the valve cone, spring and O-ring in the valve seat.

4. Close the check valve with screw plug and O-ring.

10.15 Solenoid valve maintenance

The machine must be isolated from the compressed air network and completely vented before un‐

dertaking any work on the pressure system.

Material Compressed air for blowing out

Cleaning cloths

Acid-free grease (e. g. Shell Retinax)

Spares

Precondition The supply disconnecting device is switched off,

the device is locked off,

the absence of voltage has been verified.

The machine is fully vented, the pressure gauge on the air receiver reads 0 bar.

The user's shut-off valve between the machine and the air network is closed.

10 Maintenance

10.15 Solenoid valve maintenance

No.: 9_9431_02 E

Service Manual 2-stage piston compressor

EPC

59

Loading...

Loading...