WARNING

Compressed air!

➤ Compressed air and devices under pressure can injure or cause death if the contained energy

is released suddenly.

➤ Do not loosen or open any component that is still under pressure.

3. Change the pressure switch setting.

Adjusting the setting Function

Cut-out pressure is to be increased. ➤ Turn the adjusting screw 3 clockwise (in

the + direction).

Cut-out pressure is to be decreased. ➤ Turn the adjusting screw 3 counter-clock‐

wise (in the - direction).

The pressure differential between cut-in and cut-

out pressure is to be increased.

➤ Turn the adjusting screw 4 clockwise (in

the + direction).

The pressure differential between cut-in and cut-

out pressure is to be decreased.

➤ Turn the adjusting screw 4 counter-clock‐

wise (in the - direction).

Tab. 29 Changing the pressure switch setting

4. Replace the cover.

The motor starting frequency is to be reduced?

➤ Increase the difference between cut-in and cut-out pressure.

➤ Add a larger air receiver downstream to increase buffer capacity.

Further information The duty cycle of the machine is given in chapter 2.14.

See table 14 for the motor starting frequency.

See chapter 2.7 for setting the pressure switch.

7.9 Option P4

Setting the regulator

The working pressure of a compressor fluctuates according to the limits set on the pressure switch.

The filter regulator unit reduces this fluctuation to the required pressure and holds it constant.

Precondition The machine is isolated from the air consumers.

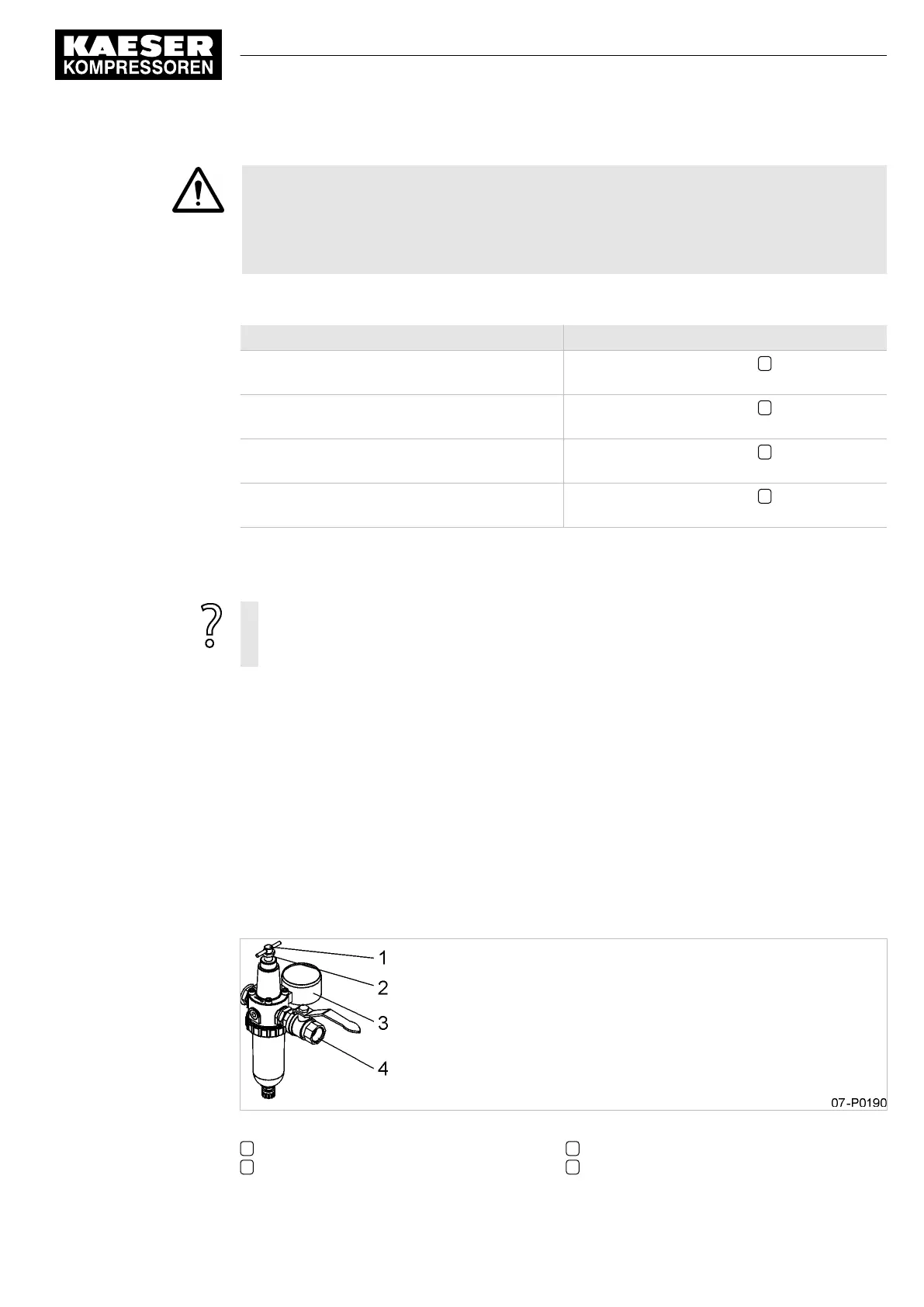

Fig. 19 Setting the regulator

1 Adjusting screw

2 Locknut

3 Pressure gauge (working pressure)

4 Compressed air outlet

7 Initial Start-up

7.9 Setting the regulator

No.: 9_9431_02 E

Service Manual 2-stage piston compressor

EPC

39

Loading...

Loading...