➤ Only a competent technician may carry out initial start-up.

Special measures for start-up after storage

Storage period

longer than

Action

12 months ➤ Change the Compressor Oil

➤ Have the motor bearings checked by an authorized KAESER Service Tech‐

nician.

36 months ➤ Have the overall technical condition checked by an authorized KAESER

Service Technician.

Tab. 26 Re-commissioning after storage

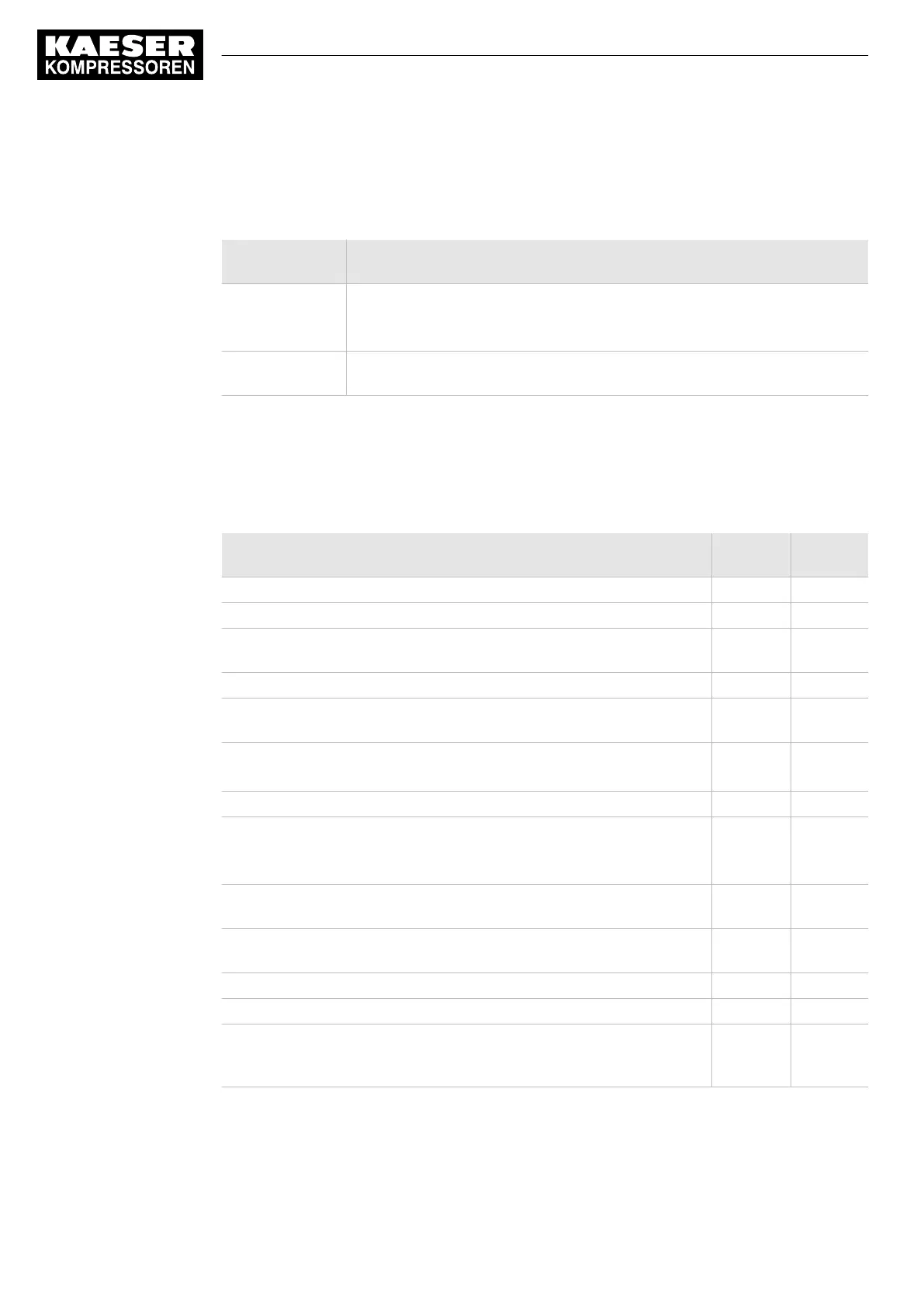

7.3 Checking installation and operating conditions

➤ Check and confirm all the items in the checklist before first start-up of the machine.

To be checked See

chapter

Complied?

➤ Are the operators fully conversant with safety regulations? –

➤ Have all the positioning conditions been complied with? 5

➤ Is a user-supplied lockable power supply disconnection device instal‐

led?

6.5

➤ Does the power supply conform to the specifications on the nameplate? 2.1

➤ Are the power supply cable conductor diameters and fuse ratings ade‐

quate?

2.12

➤ Have all electrical connections been checked for tightness?

➤ (Repeat check after 50 operating hours)

–

➤ Is the connection to the air main made with a flexible hose? 6.4

➤ Sufficient oil in the crankcase?

(oil in the sight gauge red zone)

➤ The oil must be changed after 50 operating hours

10.8

➤ Motor protection device adjusted correctly with regard to the engine

power?

7.4

➤ Oil level monitor connected?

(external controller)

6.6.1

➤ ECO-DRAIN condensate drain connected externally? 6.6.3

➤ Is the machine firmly anchored to the floor? 6.6.2.1

➤ Are all access doors closed and latched and all removable panels in

place and secured?

(sound enclosure)

–

Tab. 27 Checklist of installation conditions

7 Initial Start-up

7.3 Checking installation and operating conditions

36

Service Manual 2-stage piston compressor

EPC No.: 9_9431_02 E

Loading...

Loading...