➤ Check operating conditions and adjust intervals as necessary; log the results in table 33 for future

reference.

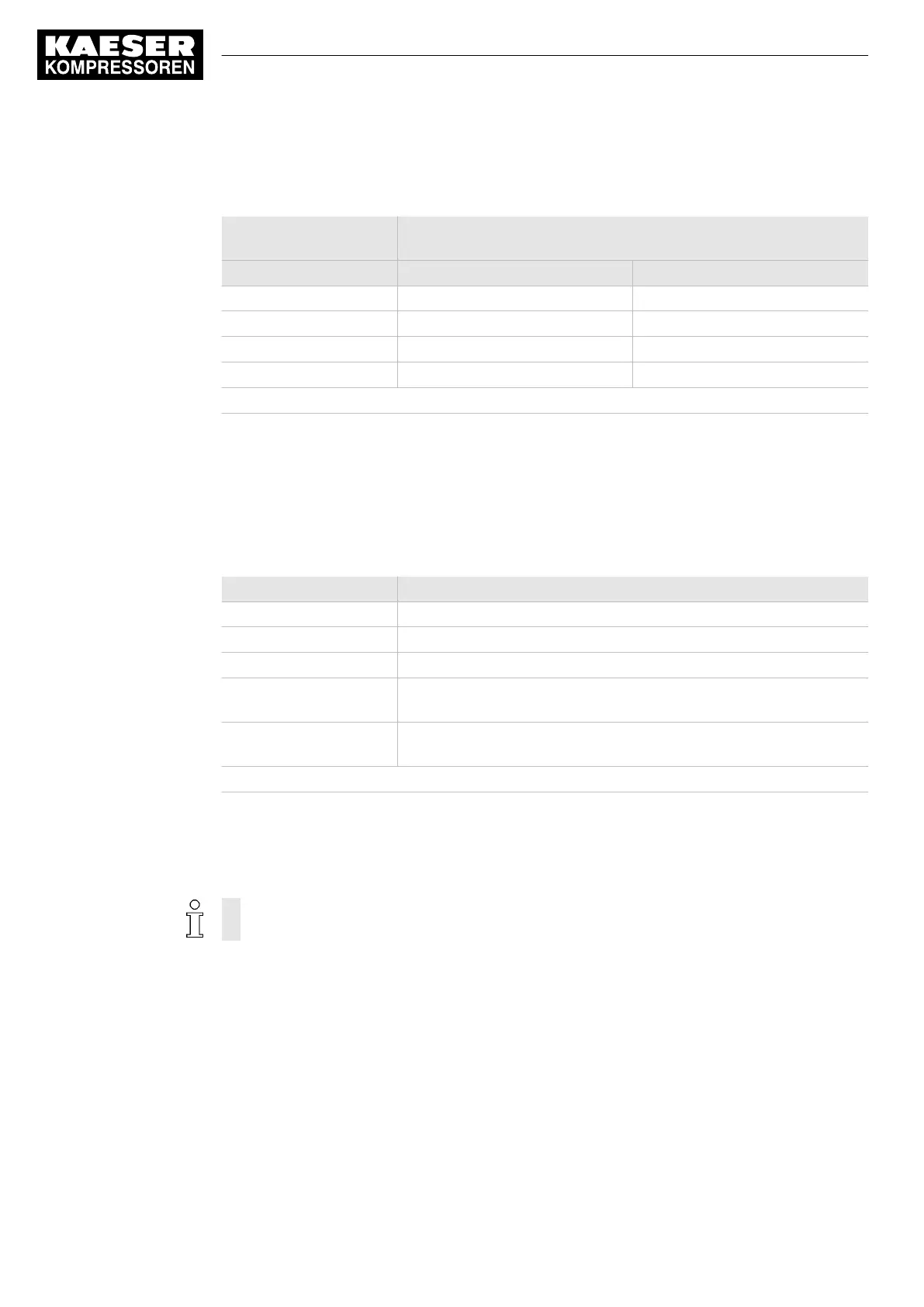

Maximum permissible oil change interval

[operating hours/years]

Compressor oil Favourable operating conditions* My operating conditions

SAE 5 W30 1000/2

VDL 150 1000/1

FGP 1000/2

S 150 2000/1

* Cool to moderate ambient temperatures, low humidity, low to average duty cycle.

Tab. 33 Oil change intervals

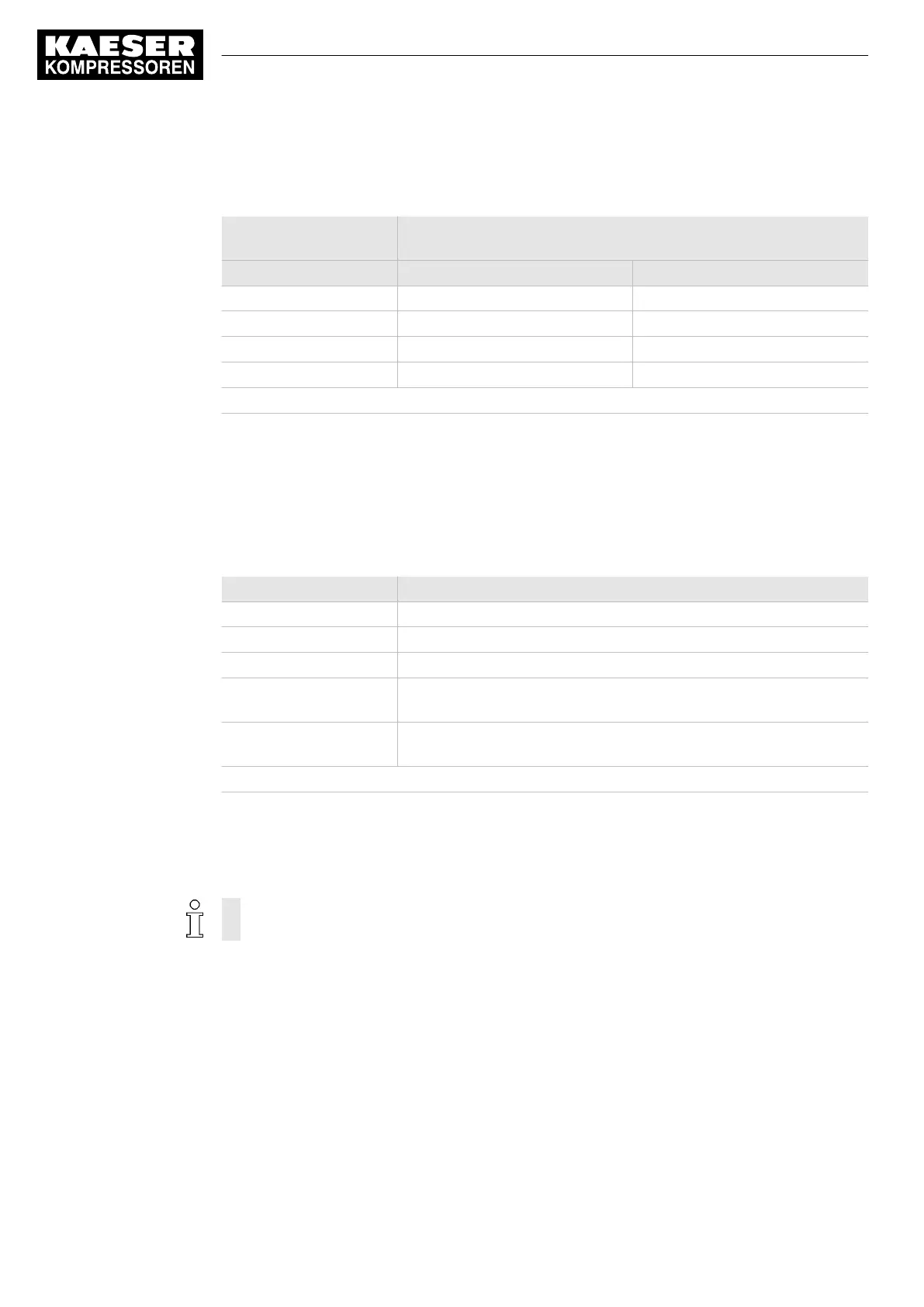

10.2.5 Regular service tasks

➤ Only an authorised KAESER Service Technician should carry out service work.

➤ When operating conditions are unfavourable (e.g. dusty or humid atmosphere) or when the

equipment is in constant use, have the service work carried out more frequently (shorter intervals).

Interval Service task

Every 2 years at least Change the air filter element

Up to 3000 h Have cylinder head and valves checked.

Up to 12,000 h Have the machine generally overhauled.

up to 12,000 h, every three

years at the latest

Have motor bearings checked.

up to 36,000 h, every six

years at the latest

Replace prepared hoses

h = operating hours

Tab. 34 Regular service tasks

10.3 Maintaining the air cooler or fan guard

According to machine model, it either has an air cooler of a fan guard.

Clogging causes overheating and machine damage.

Regular cleaning ensures reliable cooling of the machine and the compressed air. The frequency is

mainly dependent on local operating conditions.

Material Brush

Vacuum cleaner

Face mask (as required)

Precondition The supply disconnecting device is switched off,

the device is locked off,

a check has been made that no voltage is present.

The machine has cooled down.

10 Maintenance

10.3 Maintaining the air cooler or fan guard

48

Service Manual 2-stage piston compressor

EPC No.: 9_9431_02 E

Loading...

Loading...