ACD320 user manual Parameter Description

- 91-

the detecting time exceeds the feedback disconnected detecting time, the system will send an

alert of feedback disconnecting failure . (U-25)

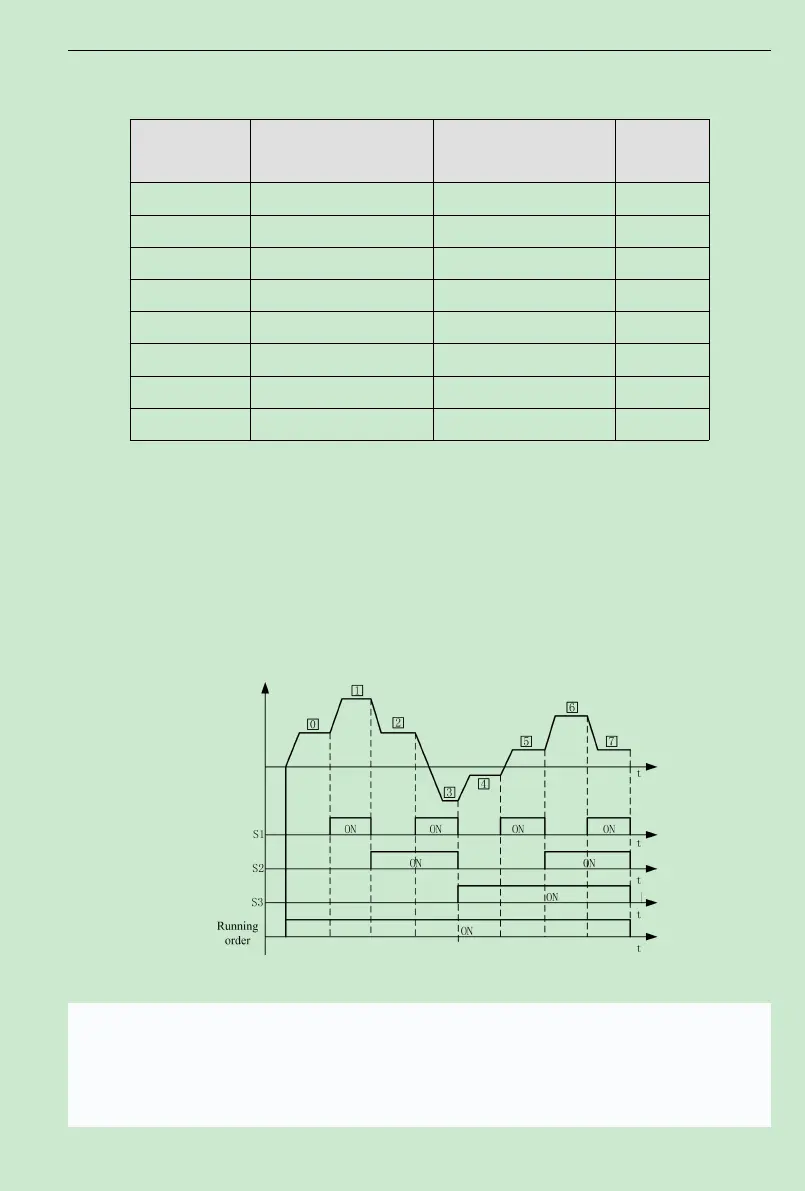

Function Code Name Setting Range

Default

Value

F4.29 Multi-Speed 0 -100.0~100.0% 0.0%

F4.30 Multi-Speed 1 -100.0~100.0% 0.0%

F4.31 Multi-Speed 2 -100.0~100.0% 0.0%

F4.32 Multi-Speed 3 -100.0~100.0% 0.0%

F4.33 Multi-Speed 4 -100.0~100.0% 0.0%

F4.34 Multi-Speed 5 -100.0~100.0% 0.0%

F4.35 Multi-Speed 5 -100.0~100.0% 0.0%

F4.36 Multi-Speed 7 -100.0~100.0% 0.0%

Note: The multi-speed symbol defines the operation direction. If it is negative, the operation

direction is reverse. Frequency setting 100.0% is corresponding to maximum frequency(F0.04).

When MI1=MI2=MI3=OFF

,

the input mode is chosen by F0.03. When terminals MI1

、

MI2

、

MI3 are not all OFF and multi-step speed run, priority of multi-step speed is higher than the

input of keyboard,simulation and communication frequency, through the combined code, 8-step

speed can be chosen at most.

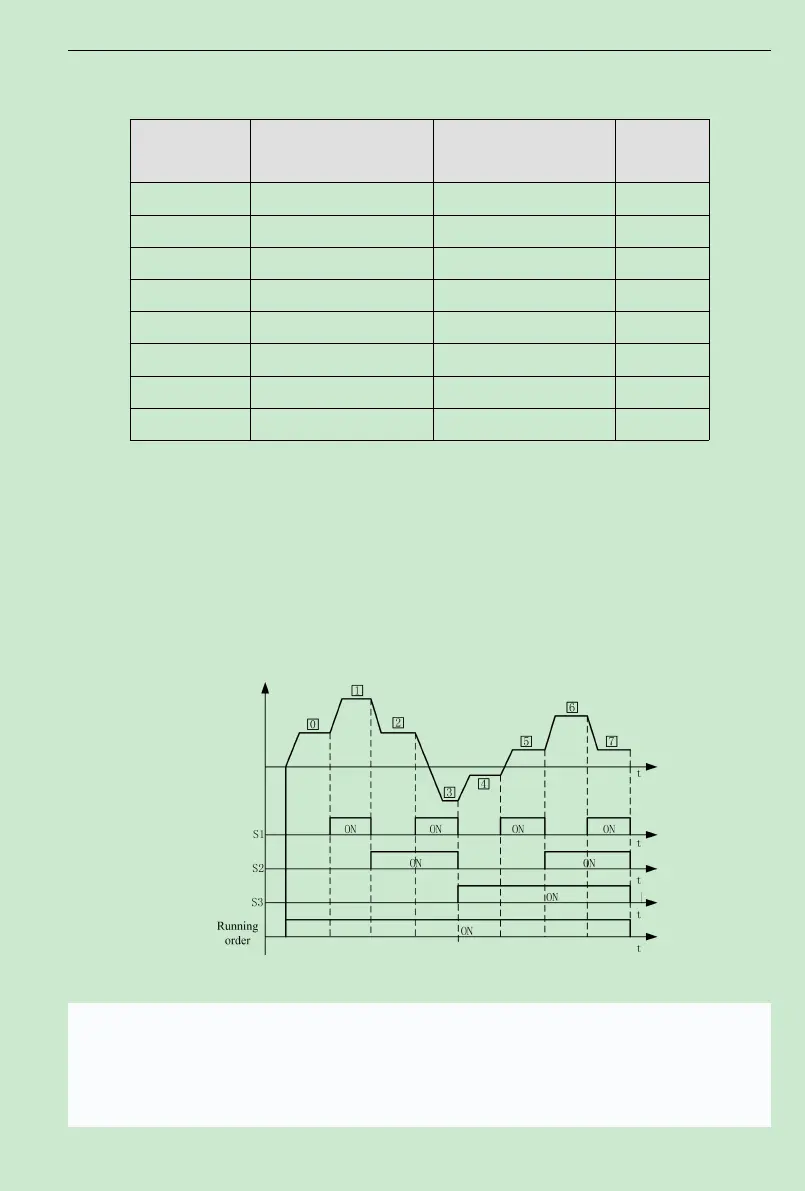

Fig.6-20multi-speed logic Diagram

The selection of stop channel starting is also determined by function code F0.01 when

inverter is running at multi- speed, and the multi- speed control process is shown in Fig.6-20.

The relation between MI1

、

MI2

、

MI3 terminal and multi-speed section is shown in the following

table.

Loading...

Loading...