12.5 Valve Guide Replacement

* Attention:

When the clearance between valve and valve guide exceeds service limit

value, please replace the valve guide. When a valve guide is replaced,

surface of valve seat retainer shall be fixed and adjusted.

Put the valve guide into the freezing chamber of refrigerator for one hour

to freeze it.

Heat with electric furnace or oven the cylinder head to

100-150℃.

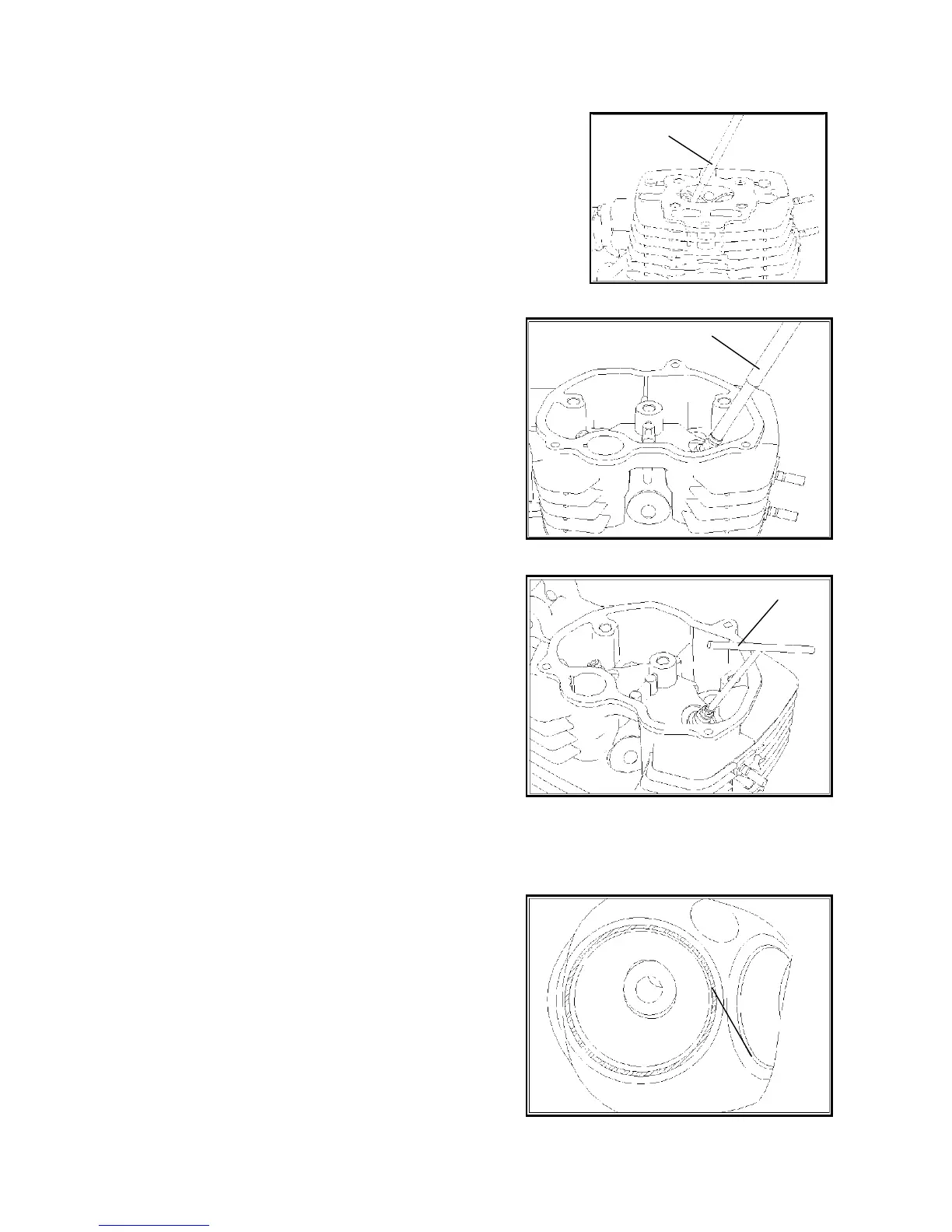

Fix the cylinder head and remove the valve guide from upper

side of cylinder head with a special valve guide remover.

Install a new O ring onto the new valve guide.

Install the valve guide from the top of cylinder head.

* Attention: Please do not hurt cylinder head while

installing valve guide.

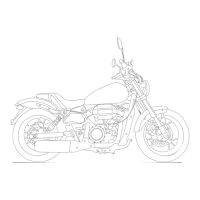

When the valve guide is inserted, fix and adjust it with a valve

guide reamer.

* Attention: When a reamer is used to cut, please apply

some amount of cutting lubricant onto it.

Rotate the reamer in clockwise direction.

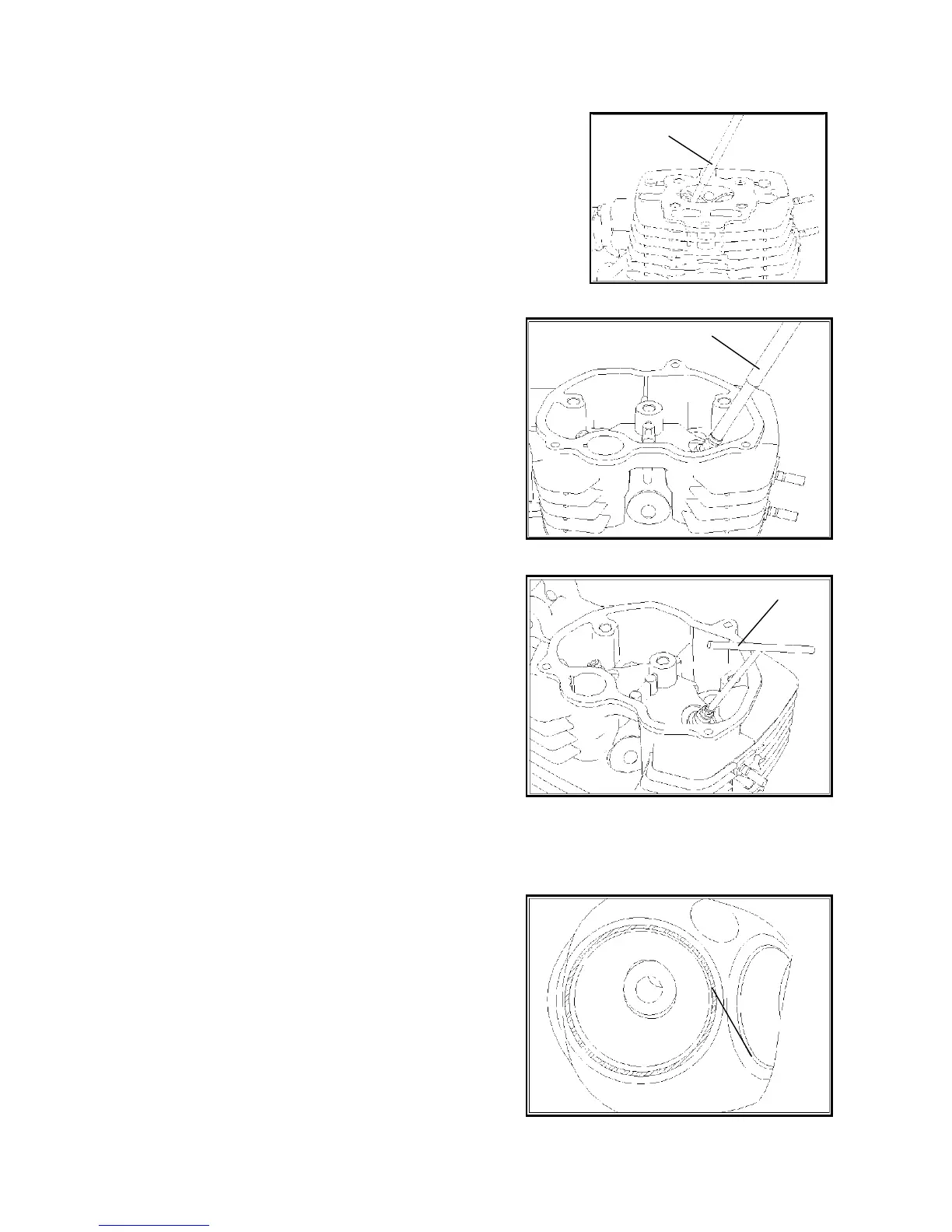

Remove carbon deposited in combustion chamber and valve

and clean thoroughly intake and exhaust valves.

Inspect width of contact surface of valve seat (width of valve

race)

Allowable limit: intake/exhaust: 1.6mm.

Loading...

Loading...