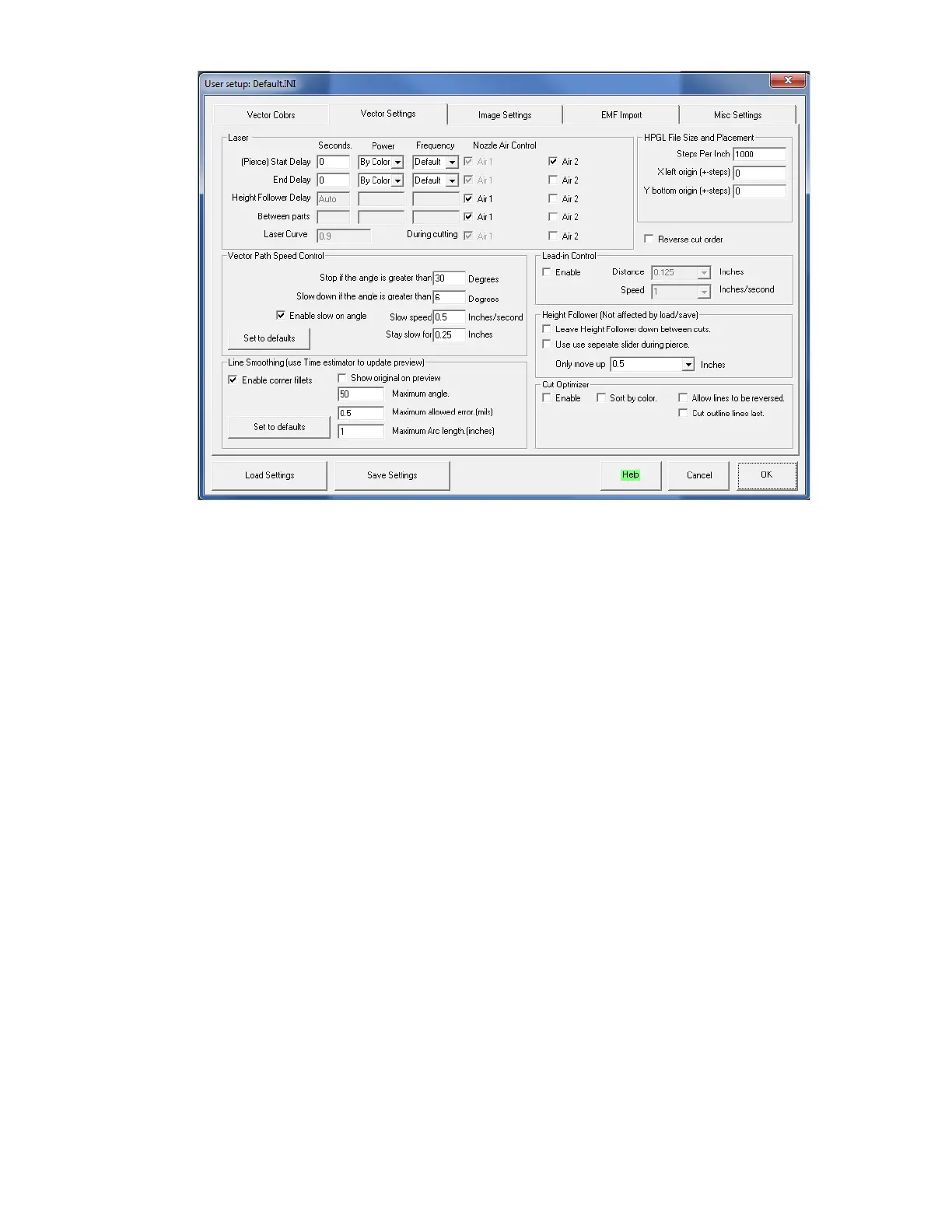

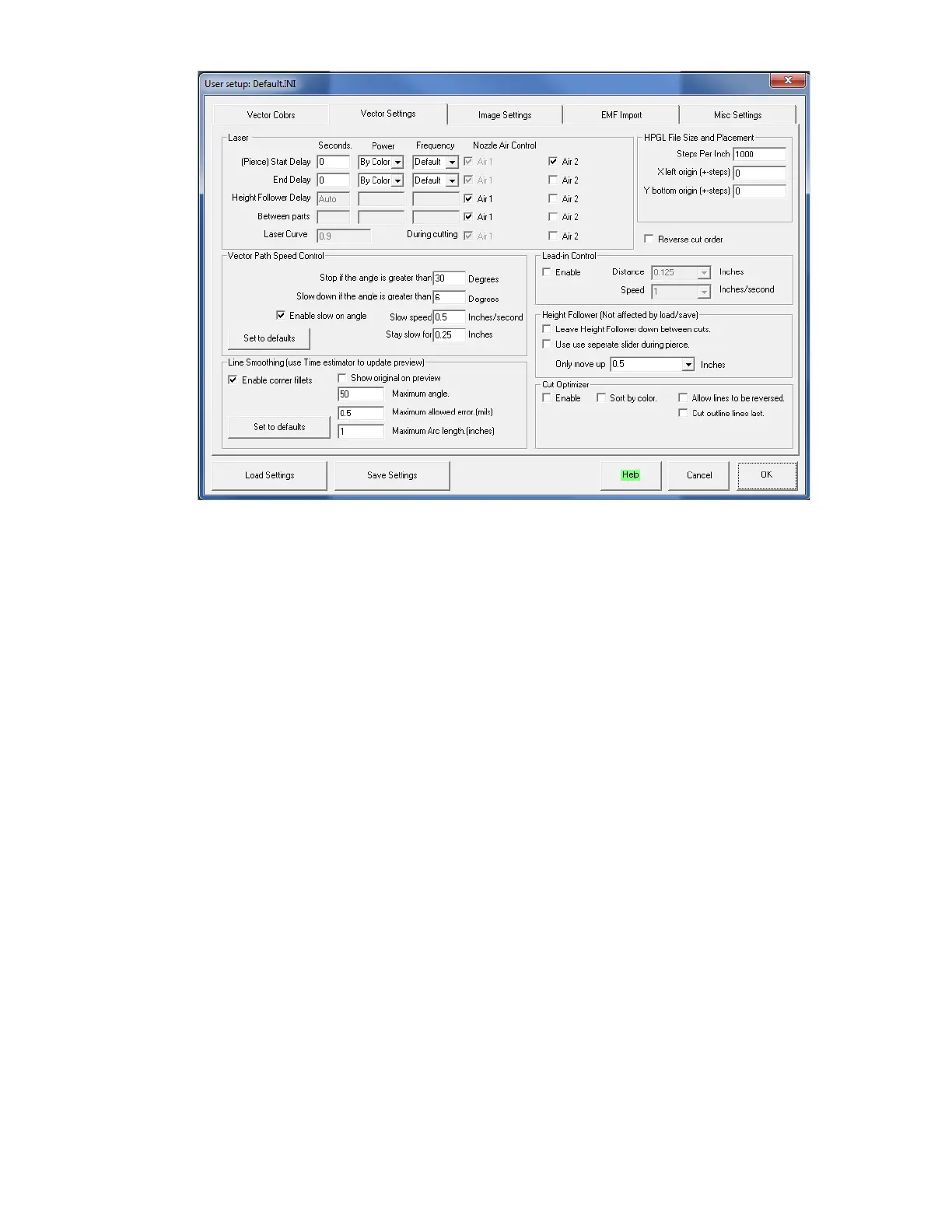

Setup, Vector Settings

Laser

Pierce Start Delay: Sets a delay which will give the laser a chance to penetrate the material to be

cut. This setting should be left at 0 for normal operation. This setting is typically used when cutting

thicker materials and metal cutting applications. The two boxes to the right allow the laser power %

and frequency to be set to a custom level during piercing.

End Delay: Sets a variable pause which will give the laser a chance to ‘catch-up’ with itself at the

end of a cut. This setting should be left at 0 for normal operation. This setting is typically used when

cutting thicker materials and metals.

Height Follower Delay: A delay that allows the height follower to move up or down into position

when starting or finishing a cut.

Laser Curve: Controls the laser power between the Laser % when starting and stopping and the

set laser power. A laser curve of 0 will map the power levels in between linearly. A laser curve of 1

will use a curve with a power of two (a = b ). Default is .9. This feature is used mostly when cutting

partially into materials to give you desired cutting depth in the corners and on straight lines.

Nozzle Air Control: Enable Air 1 and Air 2 during different settings.

Lead in Control

Enable: Turns ON and OFF the Lead-In Control. This will allow you to cut at a slower speed for a set

distance.

Distance: Distance the lead-in is effective for.

Speed: Speed to go for this lead-in distance.

27

Loading...

Loading...