motors to have a slight delay between accelerating and decelerating. In Vector cutting, it will make

smoother cuts and in Raster engraving it will allow for crisper images. The max this number can be

set to 100.

Slow down on curves

When enabled, allows for smooth transitions when cutting square corners, arcs and radiuses.

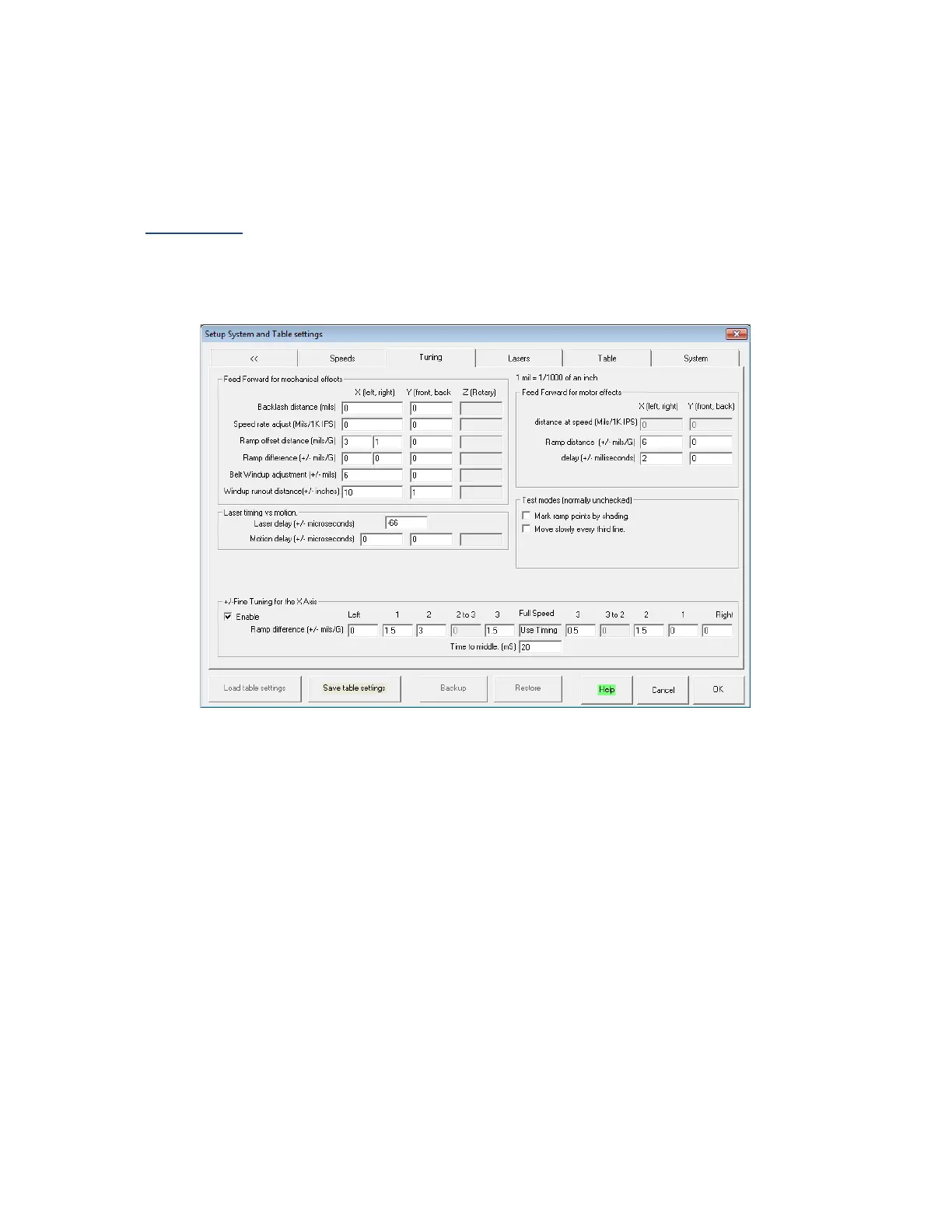

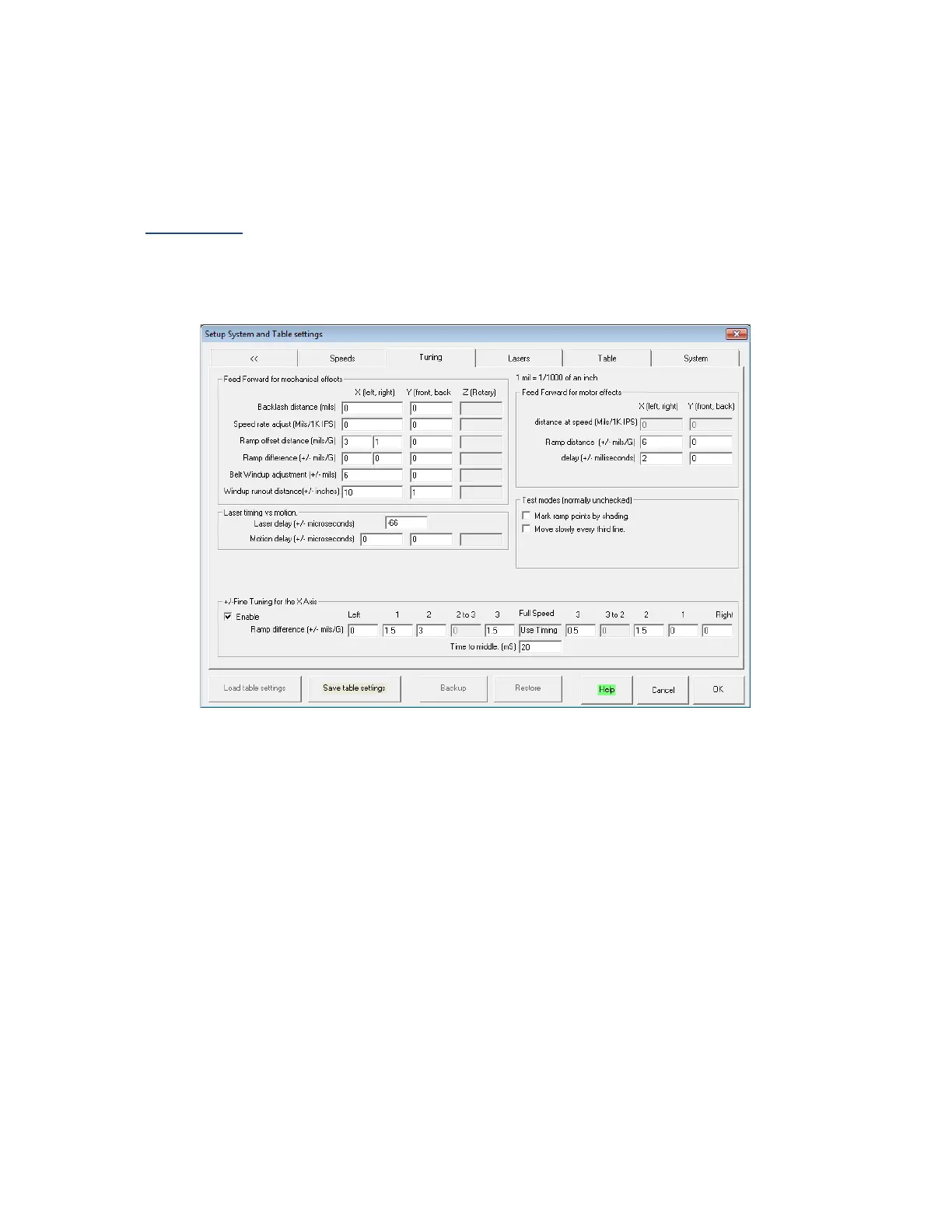

Tuning Tab

This section is for aligning your system when it is raster engraving. Please refer to the System

Calibration section of this manual for complete instructions on how to perform the dot alignment

test.

NOTE: CONTACT KERN SUPPORT FOR CORRECT SETTINGS

Table Settings, Tuning

Feed Forward (For Mechanical Effects)

Backlash Distance: Not currently used.

Speed Rate Offset: Not currently used.

Ramp Offset Distance: Used for the dot alignment, but at a speed of 130 inches/sec or 150

inches/sec, depending upon if the metal cutting option is prevalent. This offset adjusts the lines

when switching from a slow speed to a fast speed on both the left and right sides of the table as the

laser head is accelerating.

Ramp Difference: The Ramp Difference will align the dots on the left and right sides of the table.

Belt Windup Adjustment: This setting is used for aligning the dots when performing a dot

alignment test. The dot alignment test is done at the factory, but may need to be done by the

customer if they have changed a laser or mechanical part. The distance offset is used to align the

dots at a slow speed (10”/sec). This number should affect the dots the full width of the table.

Windup Runout Distance: Call Kern

35

Loading...

Loading...