ECO GOLD

25/08/2011/ YACE0088 Maintenance 57

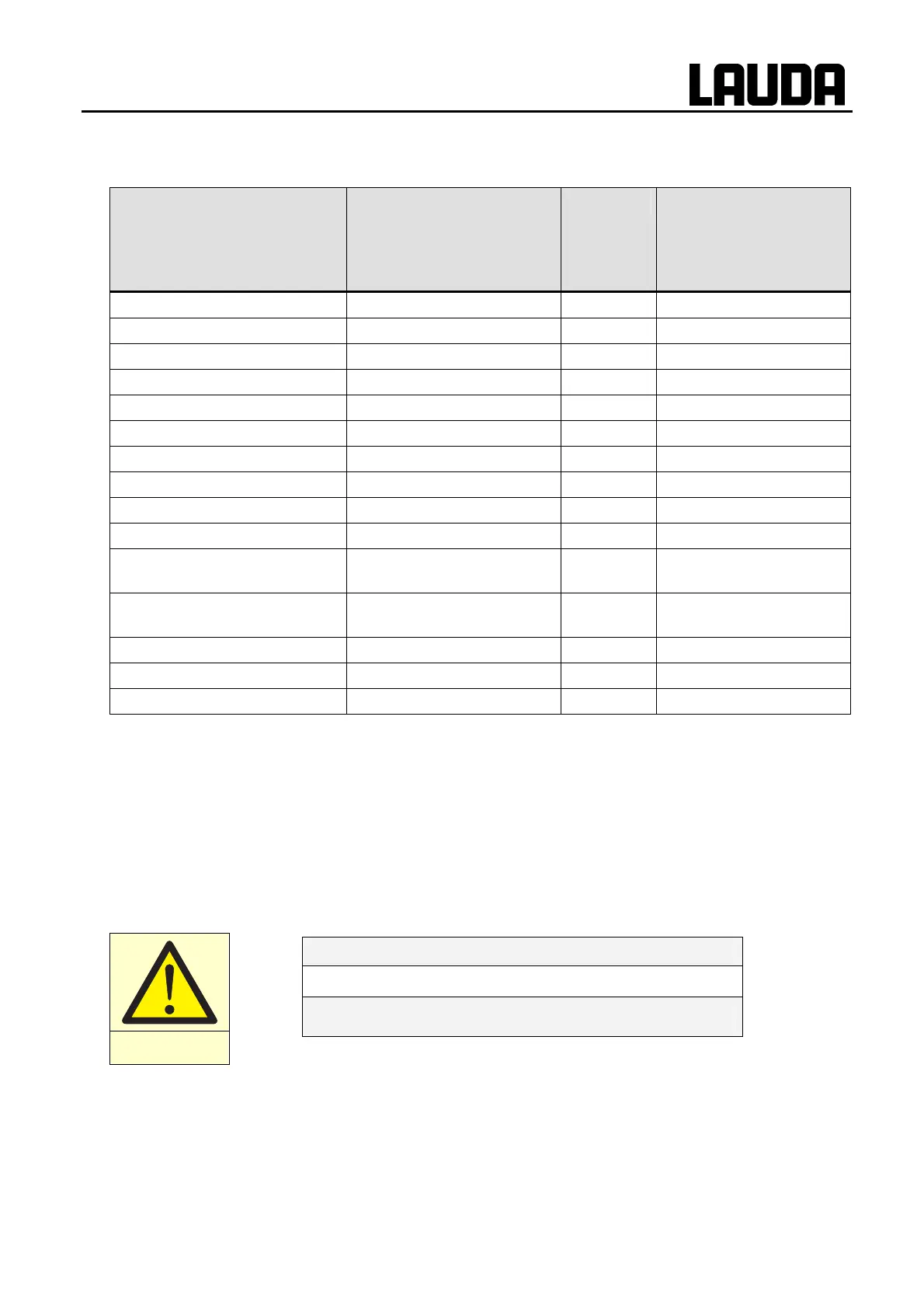

8.3.2 Servicing intervals to VDI 3033

Device part Mandatory for initial opera-

tion and before any longer

unsupervised operation,

then with recommended

frequency

Section Remarks

Complete device

External condition of device Monthly

Heat transfer liquid

Inspect the heat transfer liquid Every six months (Ì 8.3.3)

Bath vessel with drain tap

Sealing Daily External inspection

External hoses

Material fatigue Monthly External inspection

Chiller

Clean the air-cooled condenser Monthly (Ì 8.3.4.1) Cooling thermostat

Clean the plug-in sieve Monthly (Ì 8.3.4.2) Cooling thermostat, water-

cooled

Decalcify the cooling water cir-

cuit

Quarterly (Ì 8.3.4.2) Cooling thermostat, water-

cooled

Electronics

Overtemperature protection Quarterly (Ì 8.1.1)

Low-level protection Quarterly (Ì 8.1.2)

Bring the device parts and accessories to room temperature before touching them.

8.3.3 Inspecting the heat transfer liquid

Contaminated or degenerated heat transfer liquid must be renewed.

The heat transfer liquid is to be checked for its usability as required, but at least every six months. Further

use of the heat transfer liquid is only permissible if the inspection indicates this.

The test of the heat transfer liquid takes place according to DIN 51529; ("Testing and assessment of used

heat carrier media"). Source: VDI 3033; DIN 51529.

Caution !

Critical temperature of the heat transfer liquid

Scalds, frostbite

• Bring the heat transfer liquid to room temperature for

the analysis.

Loading...

Loading...