OPERATION

The function

of

the governor is to maintain, within certain limits, a desired engine speed, even

though the operating load may vary.

The governor assembly rotates with the crankshaft. As engine RPM increases the four steel

balls move up ramps forcing the governor assembly to slide down on the crankshaft. This

downward force is counterbalanced by the governor spring which holds the throttle open.

Governor spring tension tends to open the throttle. The action

of

the steel balls, which are

controlled by centrifugal force tends to close the throttle. The engine RPM at which these

two

forces balance is called the governed speed. The governor RPM is changed by adjusting

governor spring tension.

ADJUSTMENT

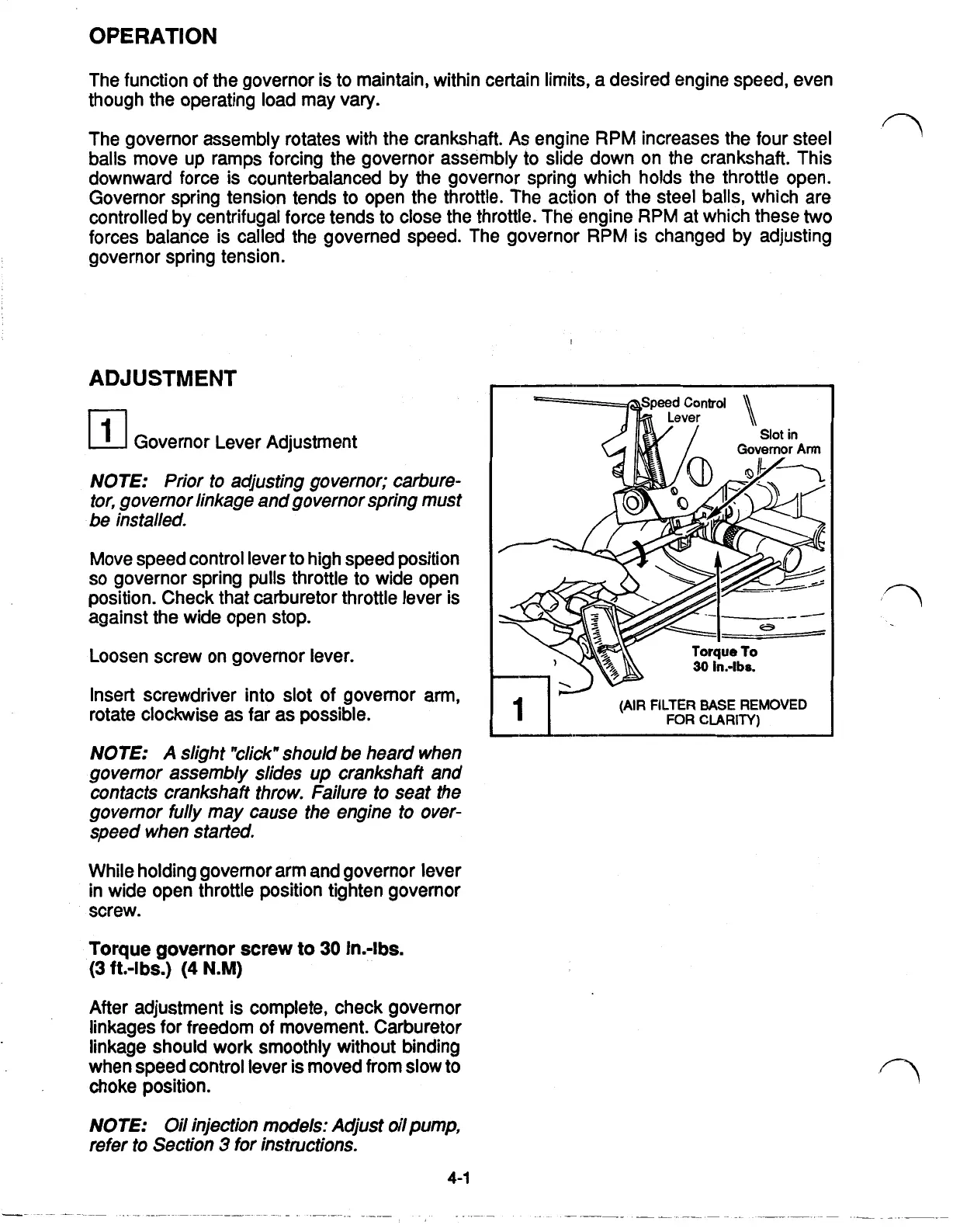

Governor Lever Adjustment

NOTE: Prior to adjusting governor; carbure-

tor, governor linkage and governor spring must

be installed.

Move speed control lever to high speed position

so

governor spring pulls throttle to wide open

position. Check that carburetor throttle lever

is

against the wide open stop.

Loosen screw on governor lever.

Insert screwdriver into slot of governor arm,

rotate clockwise

as

far as possible.

NOTE: A slight "click" should be heard when

governor assembly slides

up

crankshaft and

contacts crankshaft throw. Failure to seat the

governor fully may cause the engine to over-

speed when started.

While holding governor arm and governor lever

in wide open throttle position tighten governor

screw.

Torque governor screw

to

30

in.-lbs.

After adjustment

is

complete, check governor

linkages for freedom of movement. Carburetor

linkage should work smoothly without binding

when speed control lever is moved from slow to

choke position.

NOTE:

Oil injection models: Adjust oil pump,

refer

to

Section

3

for instructions.

(3

ft.-lbs.)

(4

N.M)

4-1

Lever

Slot

in

Governor

Arm

(AIR

FILTER

BASE

REMOVED

FOR

CLARITY)

I

Loading...

Loading...