Leerjet 35/36 Developed for Training Purposes 6-13

February 1998

Servicing

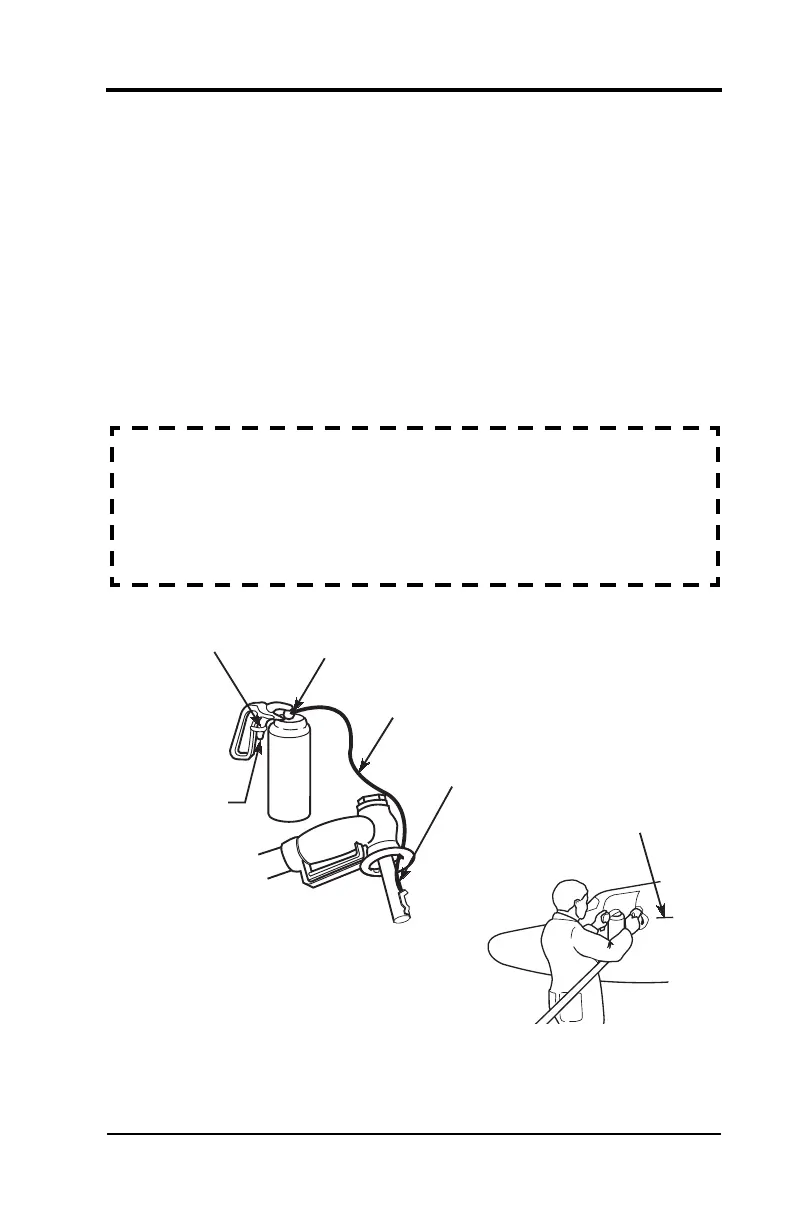

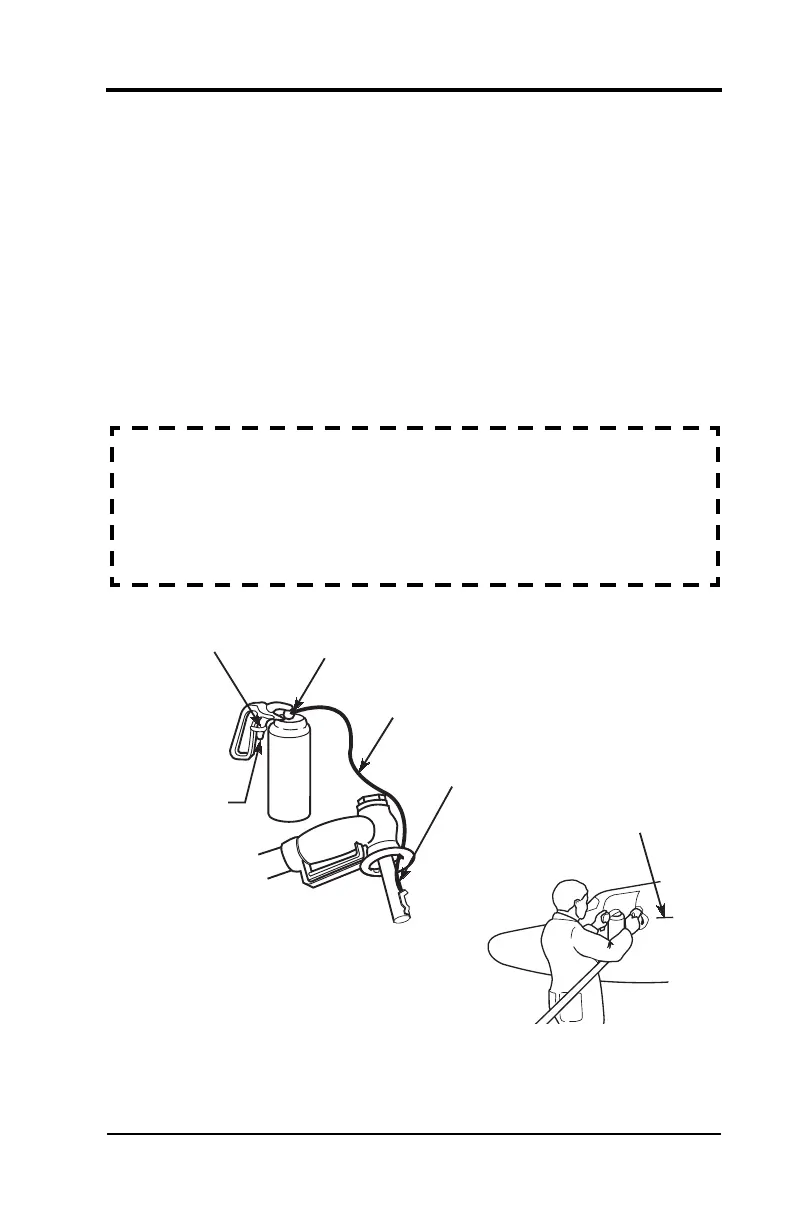

To blend anti-ice additive:

Prist Blender . . . . . . . . . . . . . . . . . . . . ATTACH TO NOZZLE

. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .(Figure 6-2)

Fuel Nozzle . . . . . . . . . . . . . . . . . . .REGULATE FLOW RATE

Flow rate should be between 30 and 50 gallons per minute.

Prist Blender . . . . . . . .DIRECT FLOW INTO FUEL STREAM

Prist Blender . . . . . . . . . . . . . . . . . . . . . . . . . . STOP FLOW

Fuel Nozzle . . . . . . . . . . . . . . . . . . . . . . STOP FUEL FLOW

Figure 6-2. Attaching Refueling Nozzle

CAUTION: Ensure additive is directed into the fuel stream.

Ensure the additive flow begins after the fuel flow starts. Stop

the additive flow before the fuel flow stops. Do not allow con-

centrated additive to contact interior of fuel tank or aircraft

painted surfaces.

BLENDER TUBE (MUST BE ATTACHED

SO THAT ADDITIVE DISCHARGES

INTO THE FUEL STREAM)

REFUELING

MAT

RING

ANTI-ICING ADDITIVE PHF-204

HI-FLO PRIST (20 FL. OZ. CAN)

FUEL NOZZLE

TRIGGER

Loading...

Loading...