FIELD DEPLOYMENT

92 LELY WELGER y RPC 445 Tornado

9.11 Setting the Bale Density (Baling Pressure)

Note!

Reduction of the bale density is recommended:

x for hey, if an airy bale core is desired.

x for extremely short and dry material, if material jams in

the feed area occur.

9.11.1 Setting the bale density – Daily operation

The desired bale density is achieved by the pressure in the

baling chamber. The individually required baling pressure is

set and indicated on the PRO-LINK control box: see

separate operating manual "PRO-LINK for RPC 445",

chapter "Setting the baling pressure setpoint".

9.11.2 Setting the bale density - Emergency operation

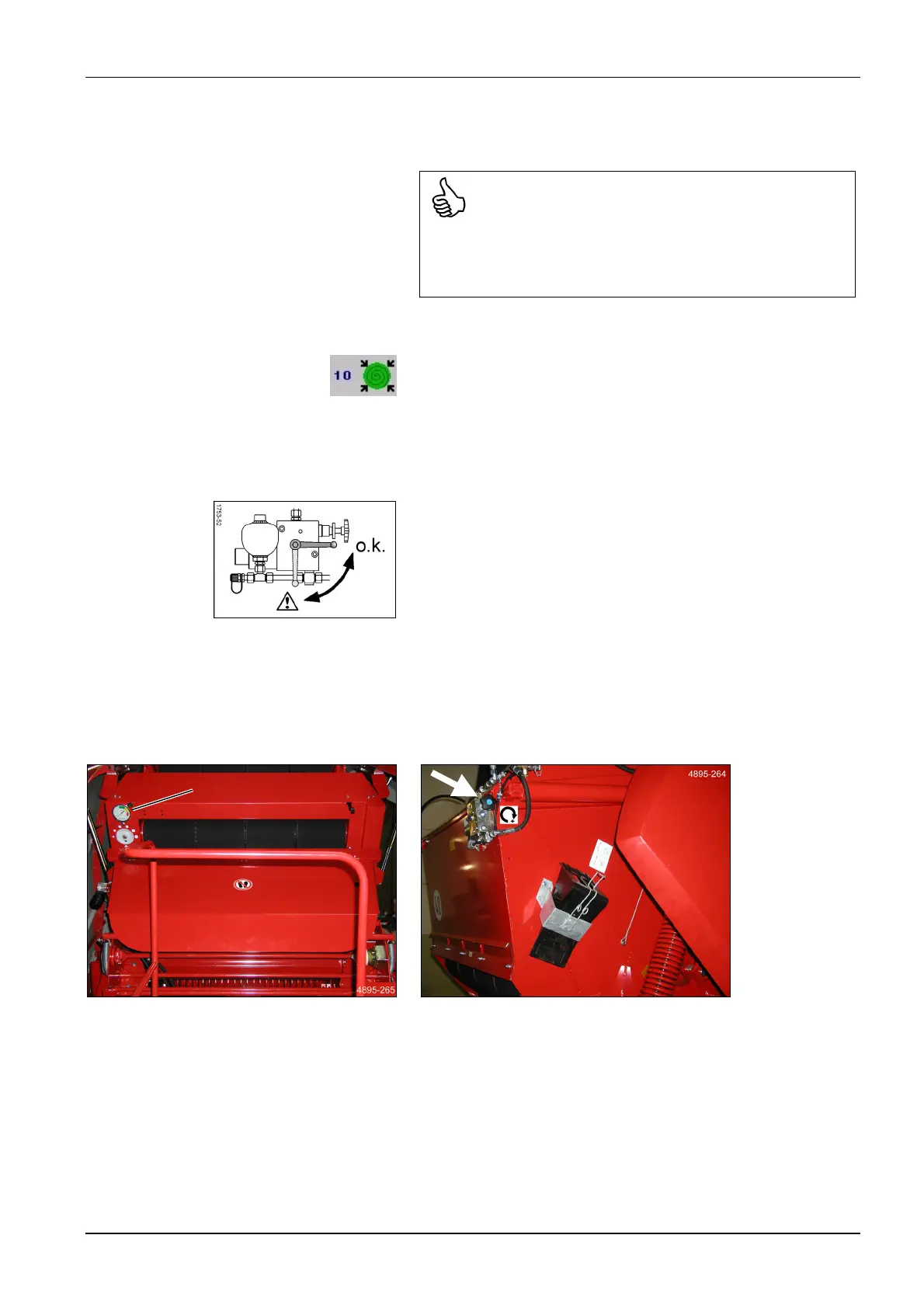

(Figure 81) A hydraulic block is located on the rear side of

the machine. (Figure 79) Move lever on hydraulic block to

vertical position.

Turn the handwheel attached to the side of the machine

clockwise up to the stop. In this position maximum pressure

(maximum bale density) is set. If a lower bale density is

desired, the handwheel can be turned back in

counterclockwise direction.

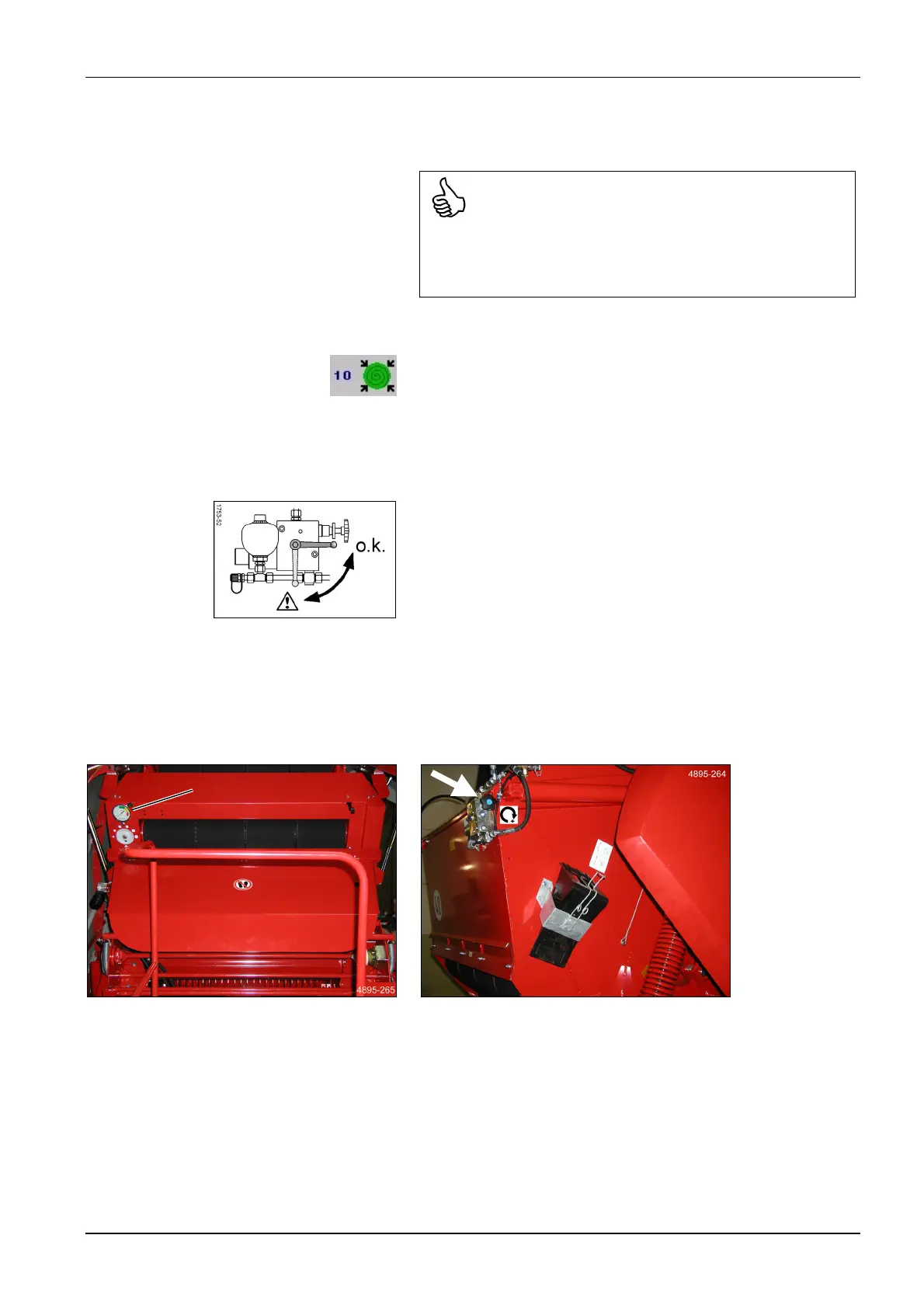

(Figure 80) The preset bale density (i. e. the baling pressure) is

indicated on the pressure gauge [1].

After emergency operation: move lever on hydraulic block

to horizontal position.

1

Figure 80 Figure 81

Figure 79

Loading...

Loading...