COMMISSIONING

LELY WELGER y RPC 445 Tornado 65

7.16 Selection of film prestretching rate

Note!

Observe film manufacturer's information.

Film prestretching can only be adjusted when no film is

inserted.

To provide for optimum bale wrapping, the film is prestretched

to a certain extent. Depending on the film type and the

production conditions the film must be prestretched to a

different degree:

55 % prestretching

70 % prestretching

79 % prestretching

For a high film quality, prestretching can be selected high.

For a low film quality, prestretching must be selected low.

High prestretching rates result in low film consumption.

Low prestretching rates result in higher film consumption.

To realise these different prestretching rates the stretcher unit

(Figure 52) can be equipped with different gear pairs:

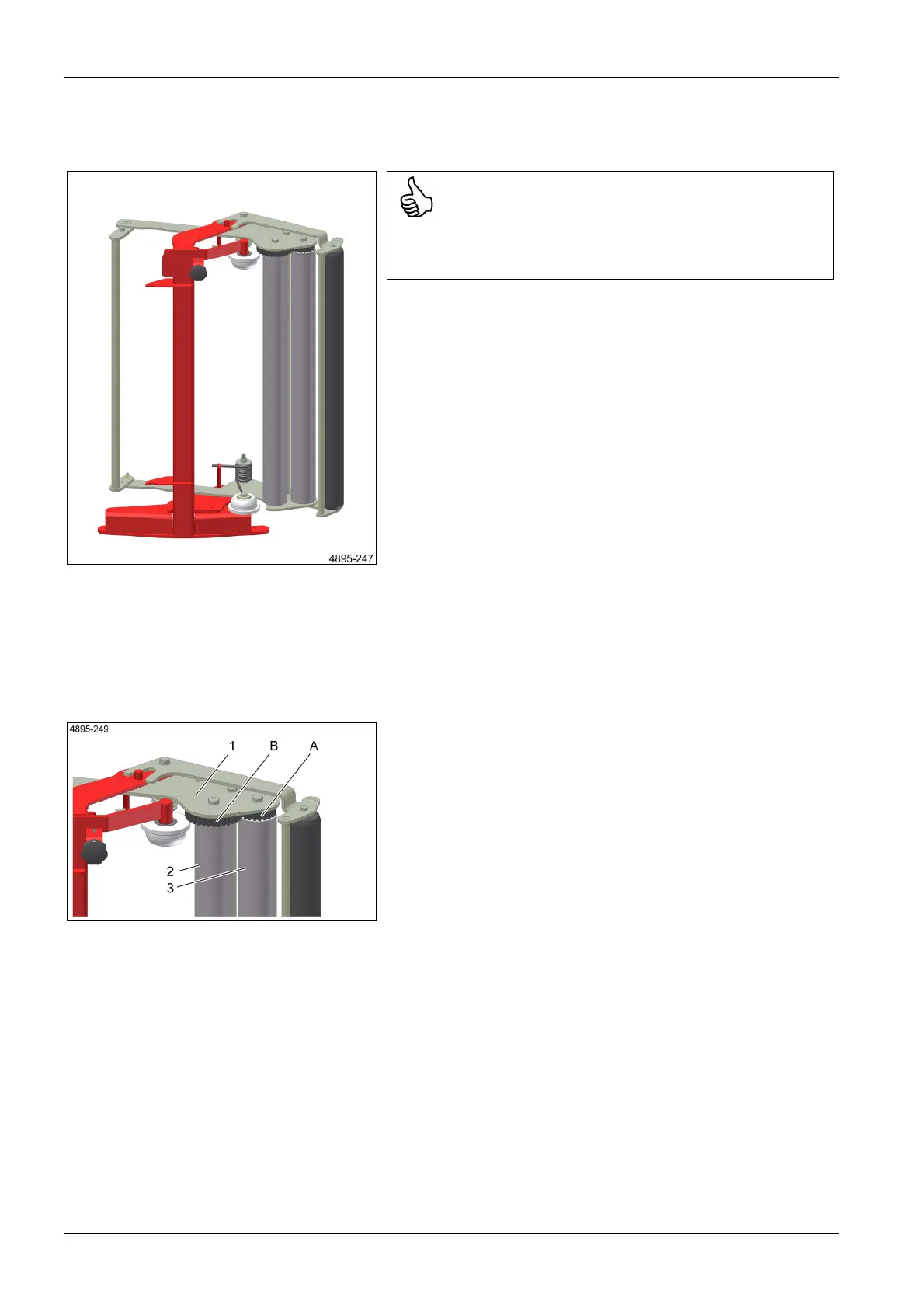

55 % prestretching:

gear pair [A] = 21 teeth, [B] = 32 teeth

70 % prestretching:

gear pair [A] = 20 teeth, [B] = 33 teeth

79 % prestretching:

gear pair [A] = 19 teeth, [B] = 34 teeth

(Figure 54) The smaller gear must always be fitted to roller end

[A]. The larger gear must always be fitted to roller end [B].

Changing the gear pairs:

(Figure 54) Remove frame [1] with the two stretch rollers [2]

and [3] from the stretcher unit.

Remove the two stretch rollers [2] and [3] from the frame

[1].

Mount the required gear wheels [A] and [B].

Applies only to the gear wheel with 19 teeth: use stud.

Install the two stretch rollers [2] and [3] in the frame [1].

Install the frame [1] with the two stretch rollers [2] and [3] in

the stretcher unit.

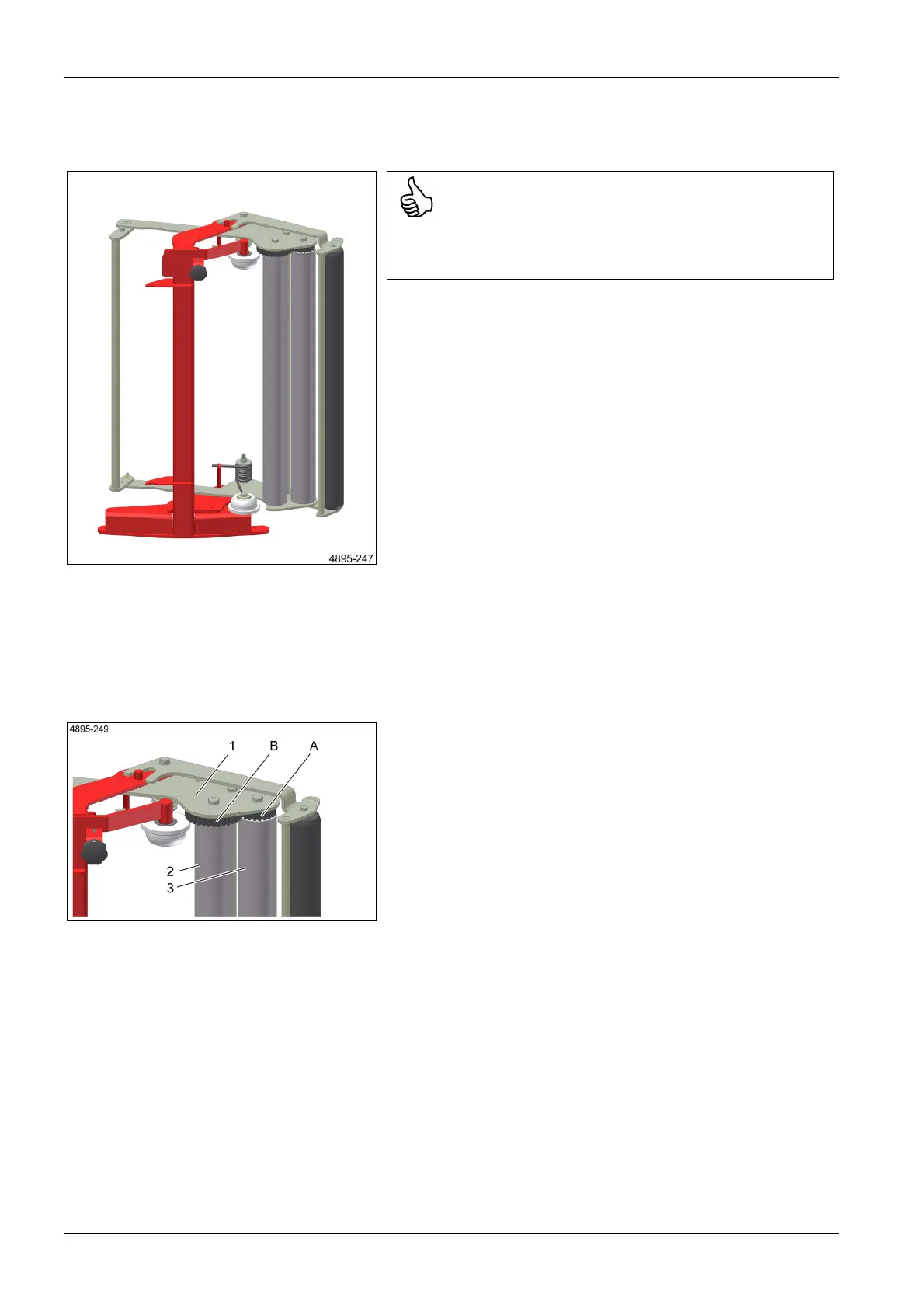

Figure 53

Figure 52

Loading...

Loading...