FIELD DEPLOYMENT

98 LELY WELGER y RPC 445 Tornado

9.14 Overload Protection

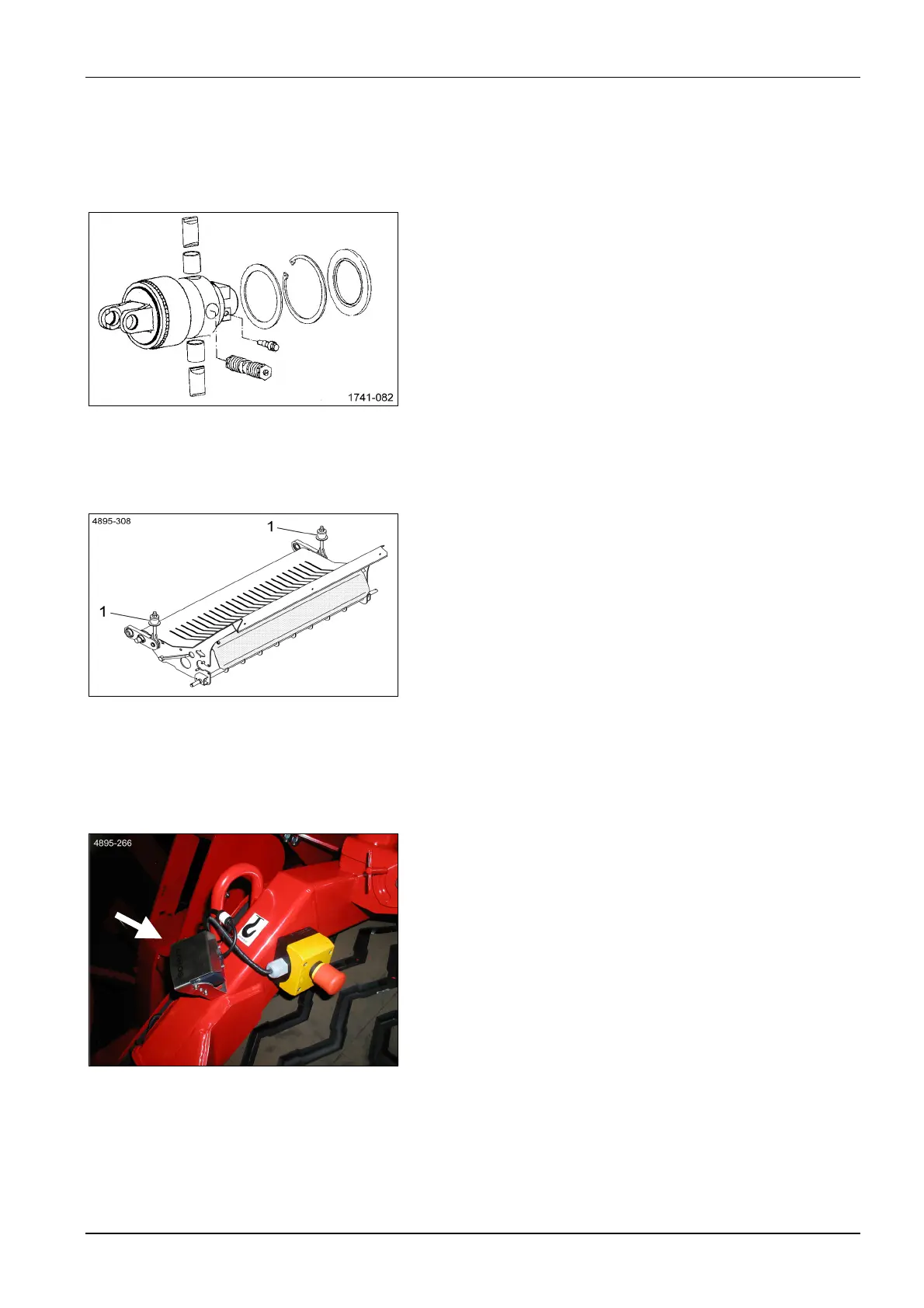

9.14.1 Drive shaft with cam-type cut-out clutch

In the event of baler overload the cam-type cut-out clutch

interrupts the driving torque.

Switch off power take-off shaft and remove cause of

overload.

After switching on the power take-off shaft, the torque

builds up again so that the machine can be put into

operation.

Avoid long and frequent overloads.

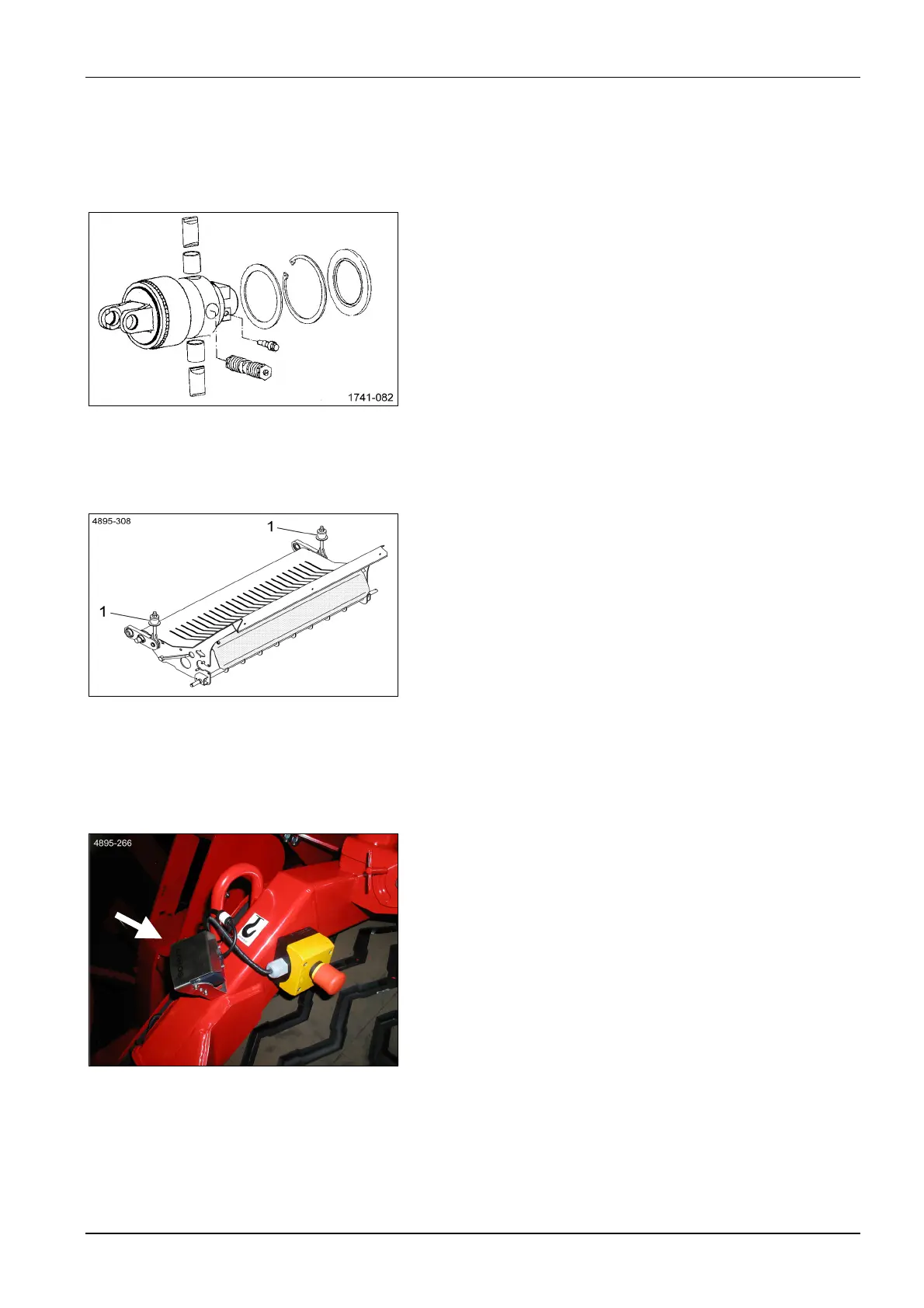

9.14.2 Elastic suspension of the feed channel floor HYDROFLEXCONTROL

(Figure 85 and Figure 87) The feed channel floor

HYDROFLEXCONTROL is elastically suspended in its pivot

point. In this way the feed channel floor can temporarily make

way for minor obstacles (e.g. material stoppers) or foreign

bodies (e.g. stones), and prevent thereby blocking of the feed

rotor.

9.15 Monitoring cameras

The bale wrapper is equipped with 2 monitoring cameras

transmitting their pictures to the monitor of the PRO-LINK

control box.

The cameras enable monitoring of the wrapping process on

the bale wrapper.

The cameras enable observation of the rear machine part

(accident prevention).

(Figure 86) The monitoring cameras are mounted on the left

and right frame of the bale wrapper.

Figure 84

Figure 86

Figure 85

Loading...

Loading...