PI1 Process Interface (optional)

Power Analyzer NORMA 4000, NORMA 5000 59

EO1111G REV G

To configure the system for motor 1, go to "Configure torque

sensor"

– or –

To configure another motor, press Next ... until the

respective motor code (M2, M3 or M4) is displayed.

The torque can be measured by means of force transducers or a

torque-measuring shaft. The signal is transferred via a ± 10V AC

output or a frequency output. In line M.. (e.g. for motor 1: M1),

adjust the following settings:

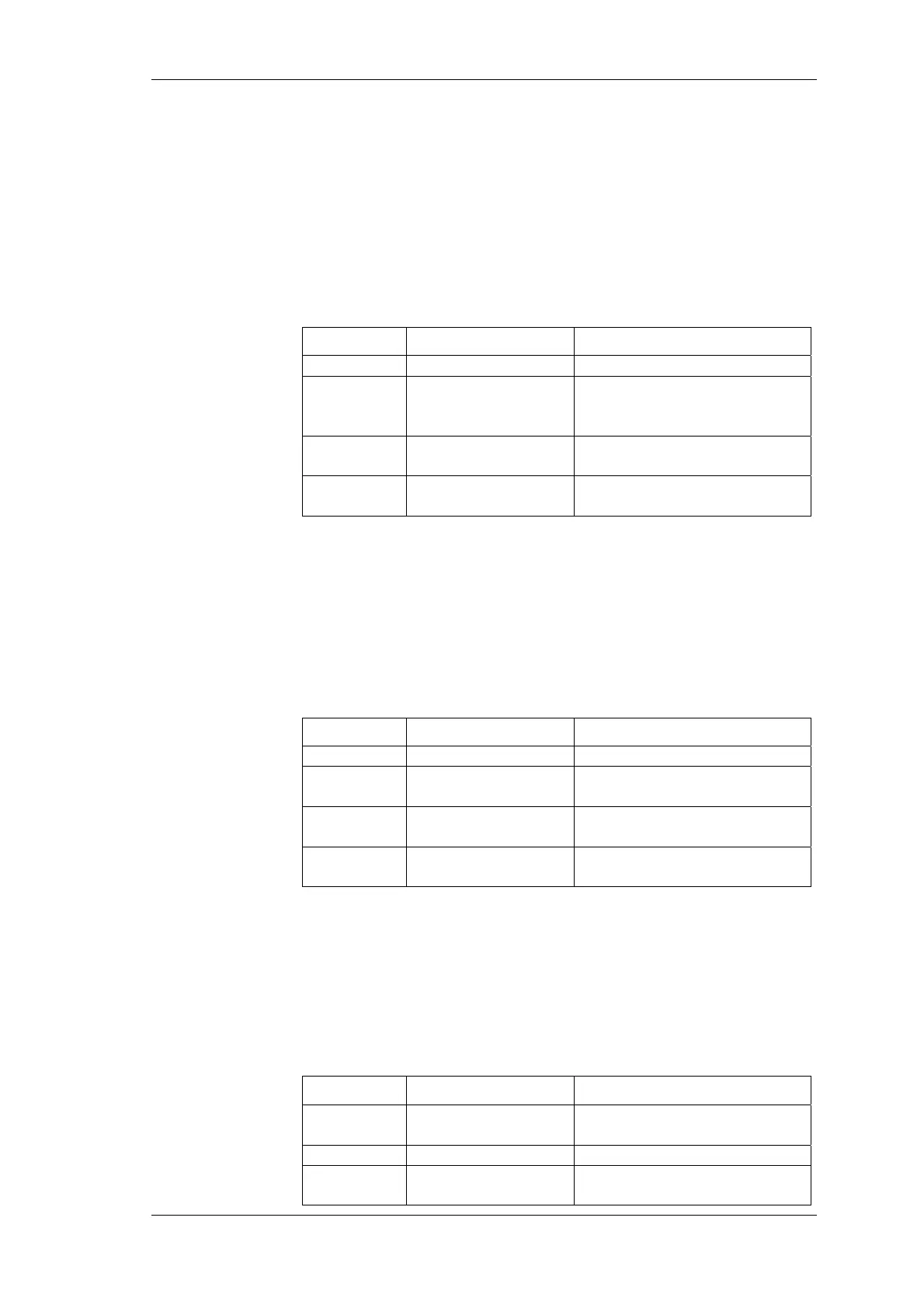

Column Settings Description

Gain 1...

Slope

Unit

Nm/Hz

Nm/V

Depending on force

transducer or sensing shaft

type

Zero 1...

Voltage or frequency

corresponding to speed = 0

Unit

Hz, V

Unit for zero, depending on

sensor type

Move the cursor to a field in line M1 and press Enter.

A list of possible options is displayed.

Select a value and confirm with Enter.

The value is now shown in the display field.

Possible speed sensors are: Incremental encoder (measuring with

TTL / AC output) or an analog signal. In line n.. (e.g. for motor 1:

n1), adjust the settings as follows:

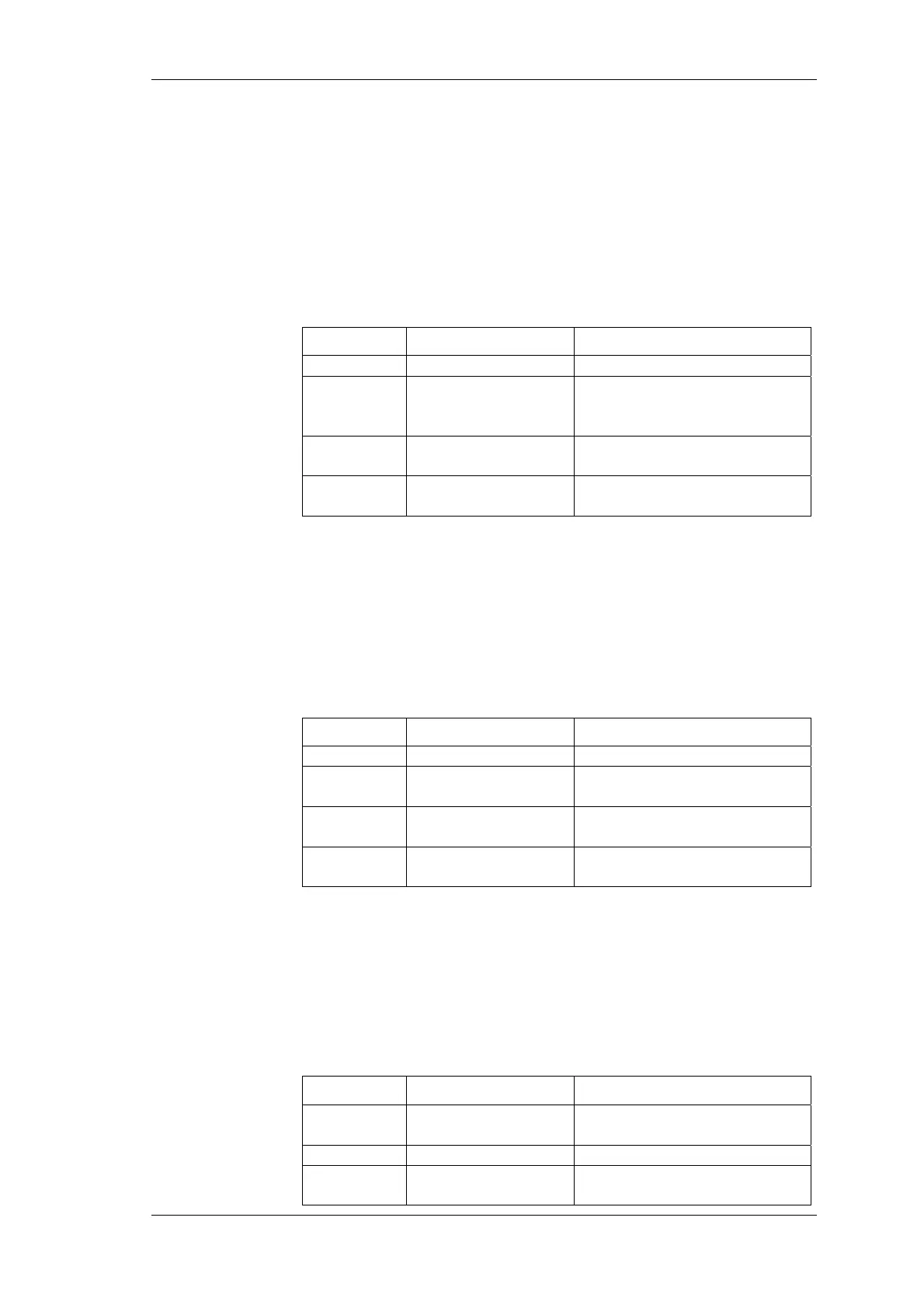

Column Settings Description

Gain 1 ...

Slope

Unit

pul/r

rpm/V

Pulses per revolution

Revolutions per volt

Zero 1 ...

Voltage or frequency

corresponding to speed = 0

Unit

Hz, V

Unit for zero, depending on

sensor type

Move the cursor to a field in line n1 and press Enter.

A list of possible options is displayed.

Select a value and confirm with Enter.

The value is now shown in the display field.

The analyzer can be used for the analysis of both motors and

generators. To configure the device, adjust the settings in line Drv1

(for motor 1):

Column Settings Description

Type MOT

GEN

Motor

Generator

PPairs 1 ... 999

Number of pole pairs

Pref P ... P3

Reference power for

efficiency calculation

Select motor

Configure torque

sensor

Configure speed

sensor

Configure motor

or generator

Loading...

Loading...