Lexmark MS31x/41x/510/610 & MX310/410/51x/61x Product Study Guide Rev 1.3

Theory of Operation

Electrophotographic Process

This monochrome laser printer uses the Electrophotographic Process (EP Process) to deliver high quality

print at high speed.

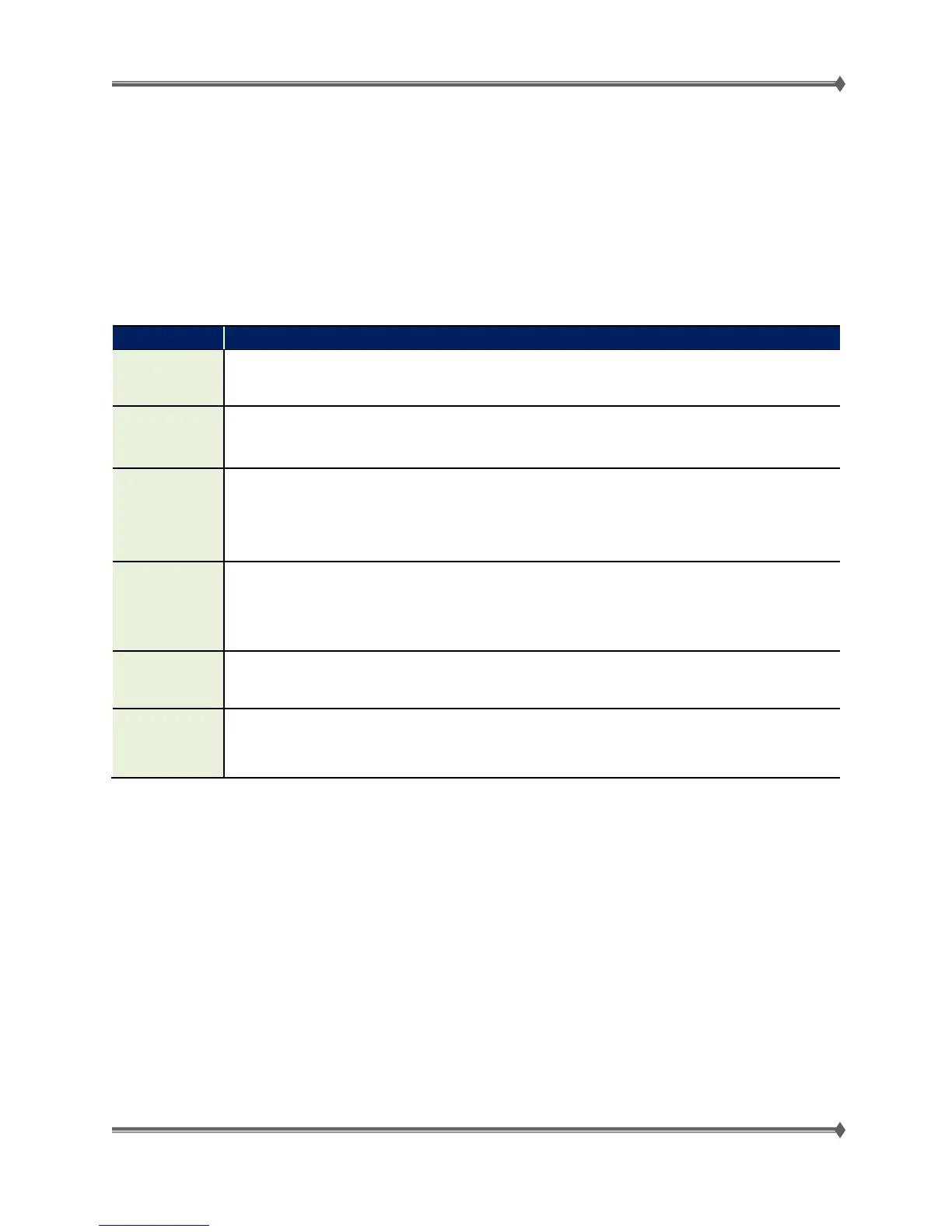

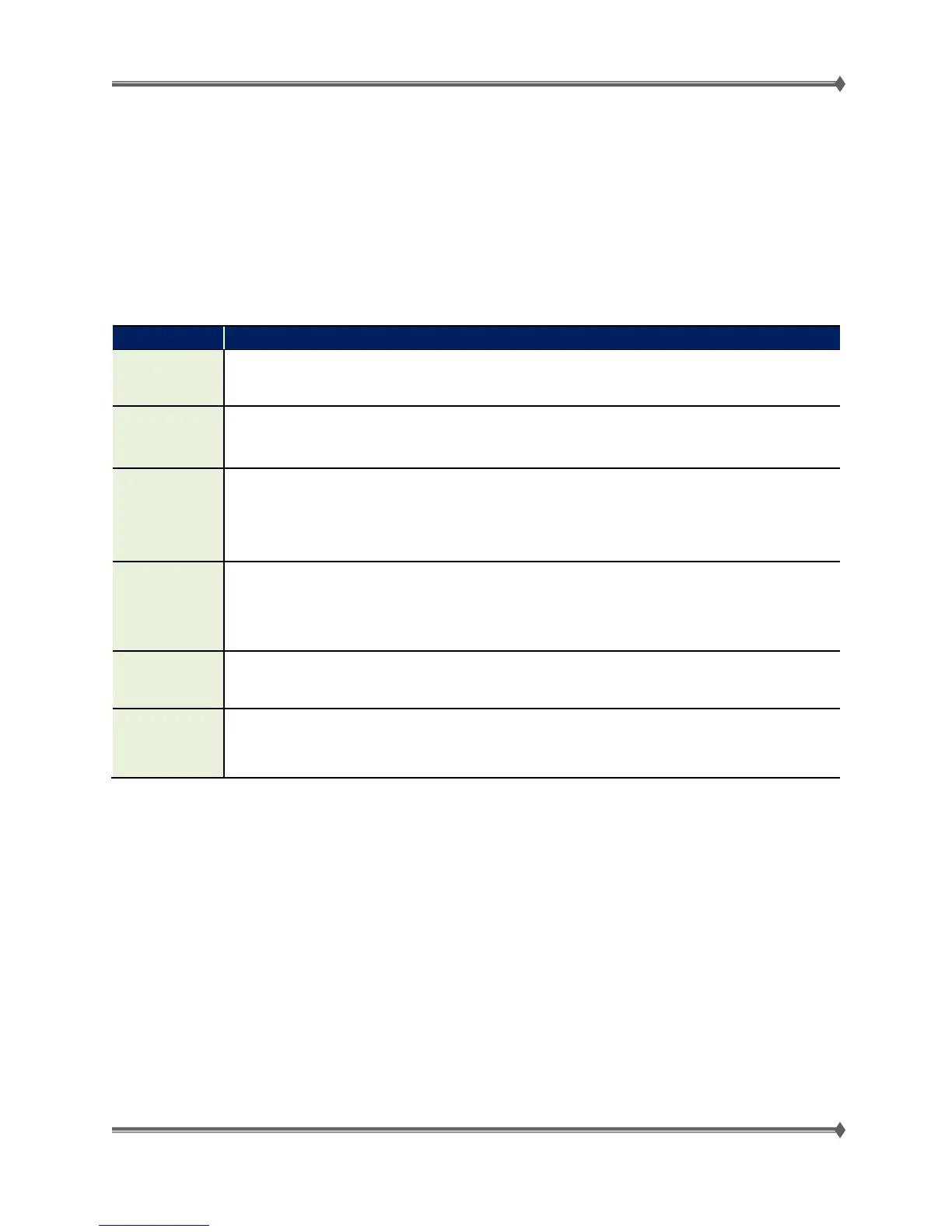

The EP Process steps are as follows:

Charge

The charge roll deposits a uniform negative electrostatic charge on the light-sensitive

surface of the photoconductor drum.

Expose

Laser light enters the cartridge and strikes the photoconductor (PC) drum in areas to

be developed, forming an invisible (latent) electrostatic image of the desired print.

Develop

Once the laser exposes the photoconductor, the HVPS sends charge to the developer

roll. Because of the charge difference between the toner on the developer roller and

the electrostatic image created by the laser, the toner is attracted to areas of the

photoconductor surface exposed by the laser.

Transfer

As the media travels between the transfer roll and the photoconductor, the transfer

roll applies a positive charge to the back of the media. This positive charge attracts the

negatively charged toner image from the photoconductor to the top surface of the

media.

Fuse

The media – now with a “toned” image – moves through the fuser assembly. Using

heat and pressure, toner is bonded permanently to the media.

Clean

The cleaning blade removes any toner that remains on the photoconductor after the

transfer process. The toner removed is collected in the Imaging Unit’s waster toner

bottle.

If a component fails, it is important to recognize at which step the failure took place. By knowing this, you

can determine the source of the problem. Understanding the EP Process is the key to troubleshooting

print quality problems.

For Training Purposes Only 7 4/21/2014

Loading...

Loading...