Lexmark MS31x/41x/510/610 & MX310/410/51x/61x Product Study Guide Rev 1.3

Paper Transport System and Enhancements

Base Engine Features and Updates

New Features

Flushing

• This new feature will improve our customer’s experience by

minimizing user interventions when getting paper jams.

• The printer will attempt to automatically move undamaged

media to the output bin that would have otherwise been

jammed inside the printer, and will automatically resume

printing.

• This feature is enabled by default. To disable, go to:

General Settings > Print Recovery > Jam Assist >

OFF/ON

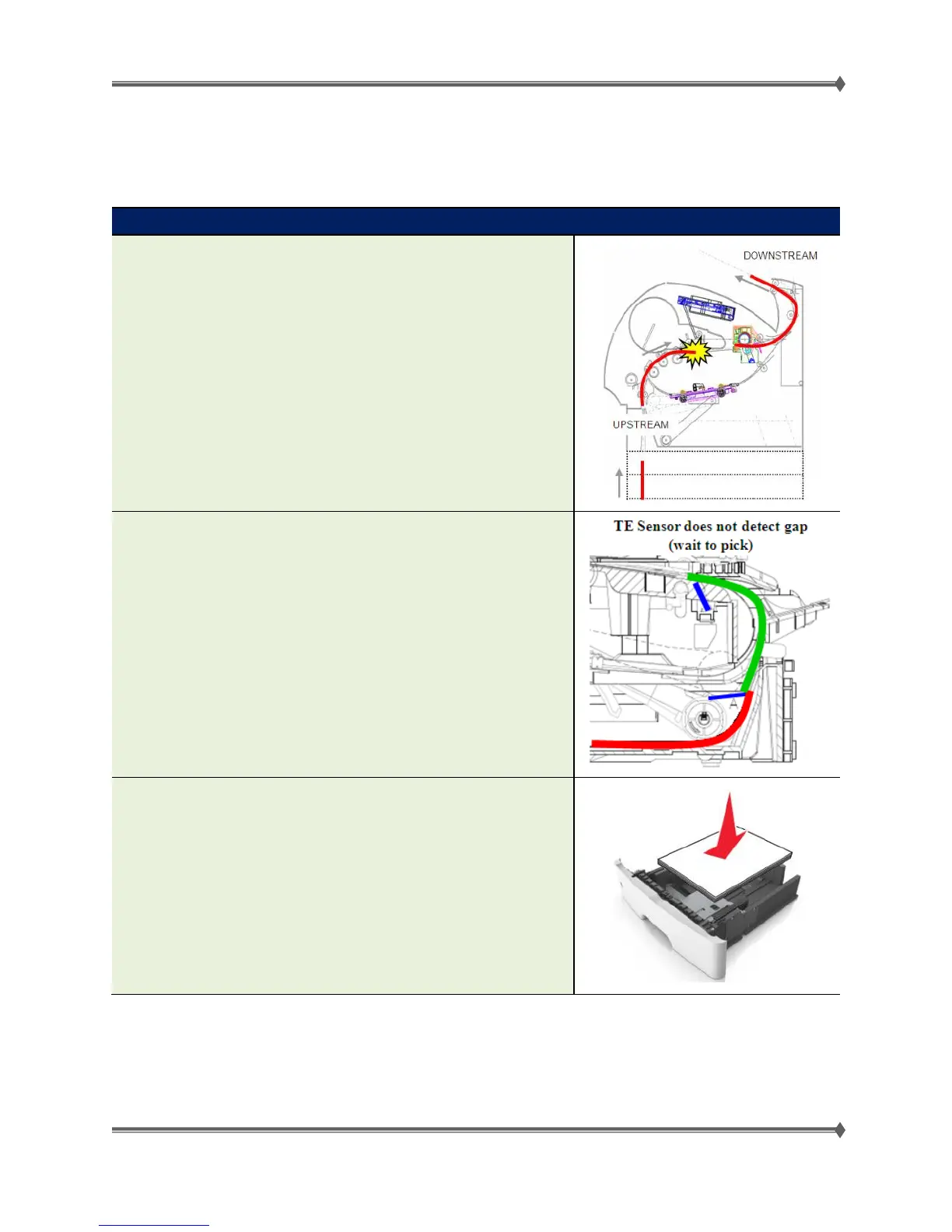

Jam Avoidance

• With the implementation of a Trailing Edge (TE) sensor and

new code algorithms, instances of getting “soft” jams and

jams caused by gap closure can be reduced.

• The printer will now have the ability to hold off future picks:

- until it detects a gap between sheets

- until the previous sheet is past input sensor

- if the previous page is measured to be of unexpected

length

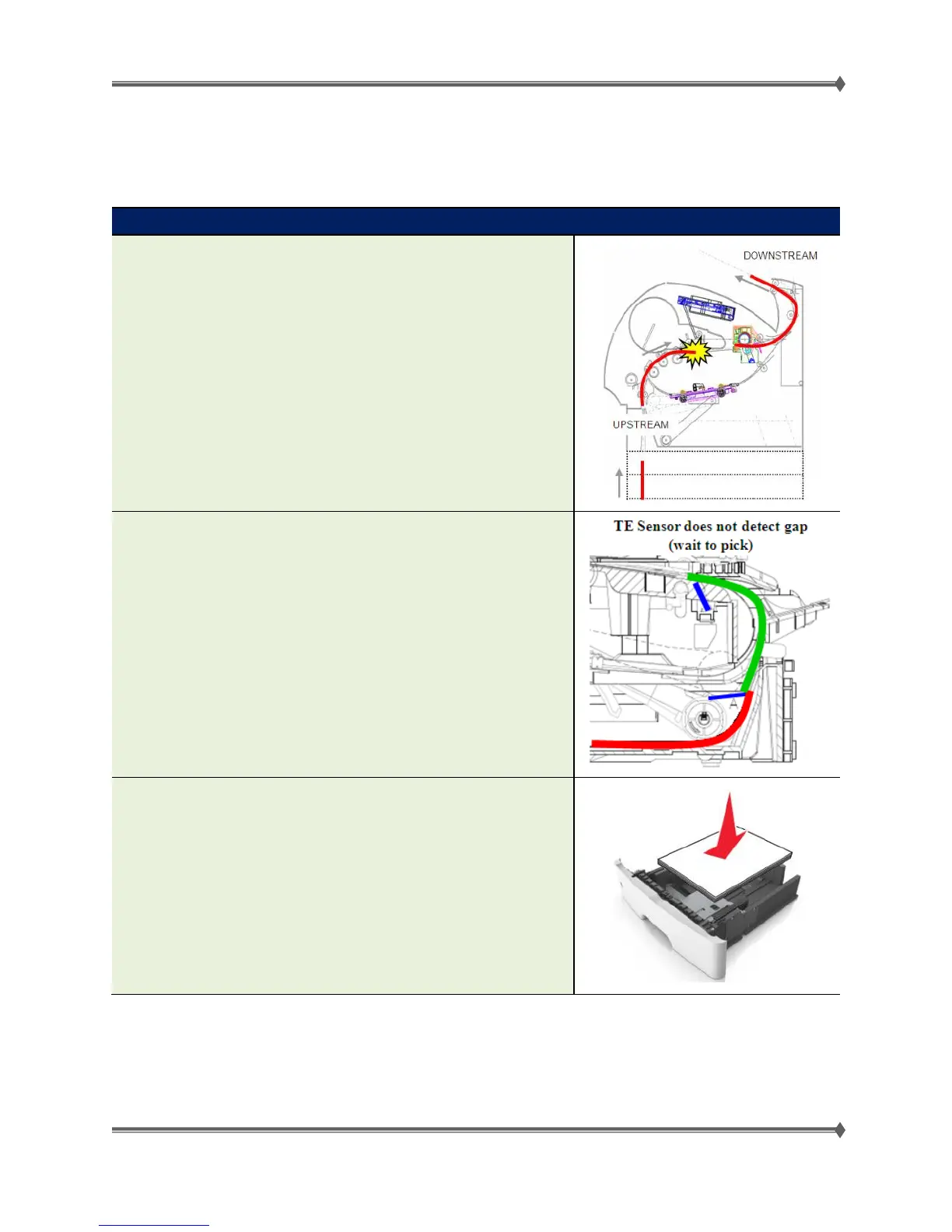

Tray Insert Design (MS510/MS610 and MX Series)

• For the said printer models, the tray insert uses the lift plate

mechanism to elevate the media during paper transport.

• The wear strips (aka dimple dams) is replaced with a new

FRU part called the separator roll assembly which is part of

the Maintenance Kit.

• Media should be fed straight in - no longer slanted.

For Training Purposes Only 9 4/21/2014

Loading...

Loading...