3.4. EXPERT MODE

Figure 3.28: Infill pattern: Octagram Spiral (318.63mm / 5m:15s)

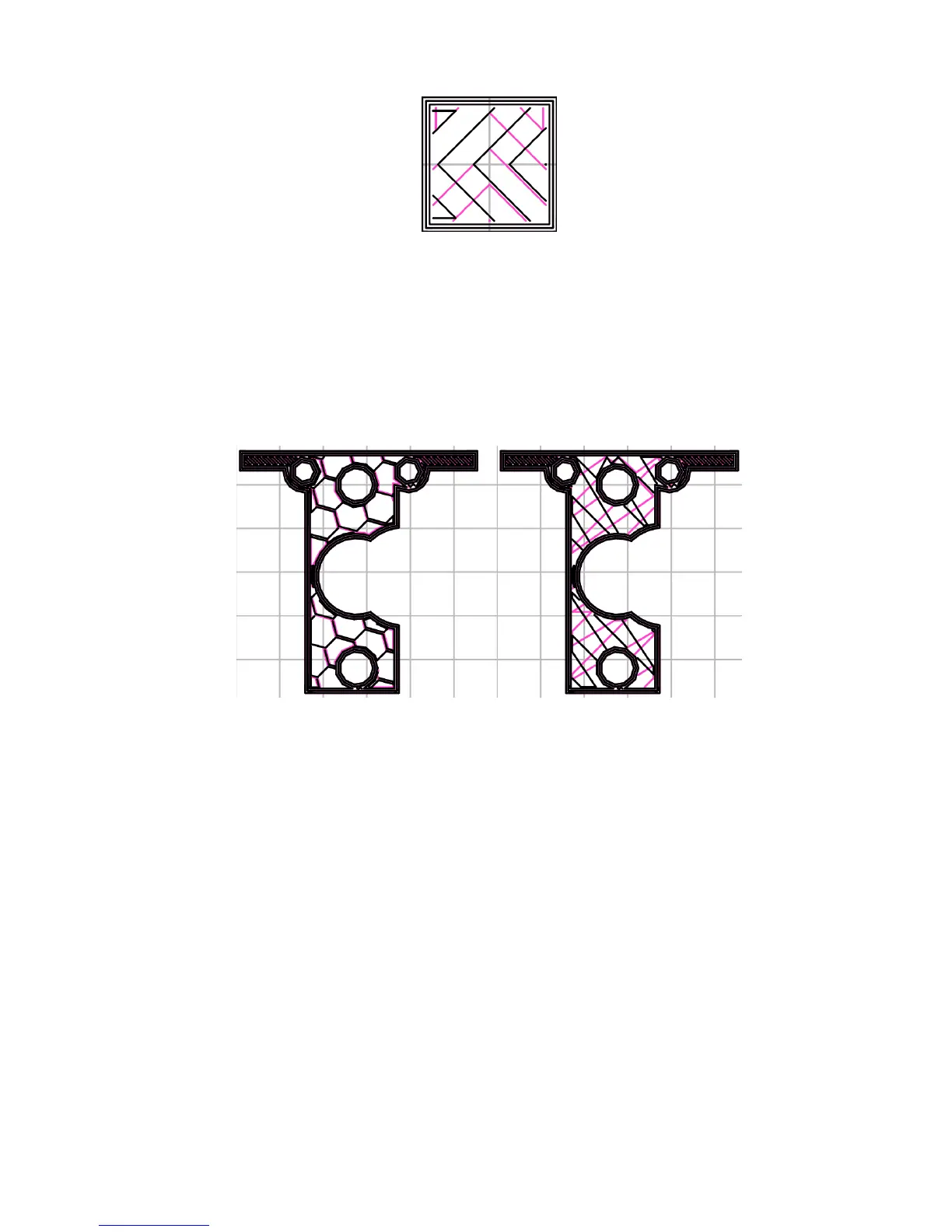

Certain model types are more suited for a particular pattern, for example

organic versus mechanical types. Figure 3.29 shows how a honeycomb fill

may suit this mechanical part better because each hexagon bonds with the

same underlying pattern each layer, forming a strong vertical structure.

Figure 3.29: Infill pattern comparison in a complex object. Left to Right:

honeycomb, line

Most models require only a low density infill, as providing more than,

say, 50% will produce a very tightly packed model which uses more material

than required. For this reason a common range of patterns is between

10% and 30%, however the requirements of the model will determine which

density is best. Figure 3.30 shows how the patterns change as the density

increases.

71

Loading...

Loading...