3.4. EXPERT MODE

• Minimum extrusion length

- Dictates a minimum number of mil-

limeters that the skirt should be, should the loop around the object

not be enough.

Cooling

Temperature plays a key part in determining print quality. Too hot and the

material deforms, too cool and layer adhesion may be problematic. Applying

cooling will allow the freshly deposited material to solidify enough to provide

a good base for the next layer, helping with overhangs, small details and

bridges.

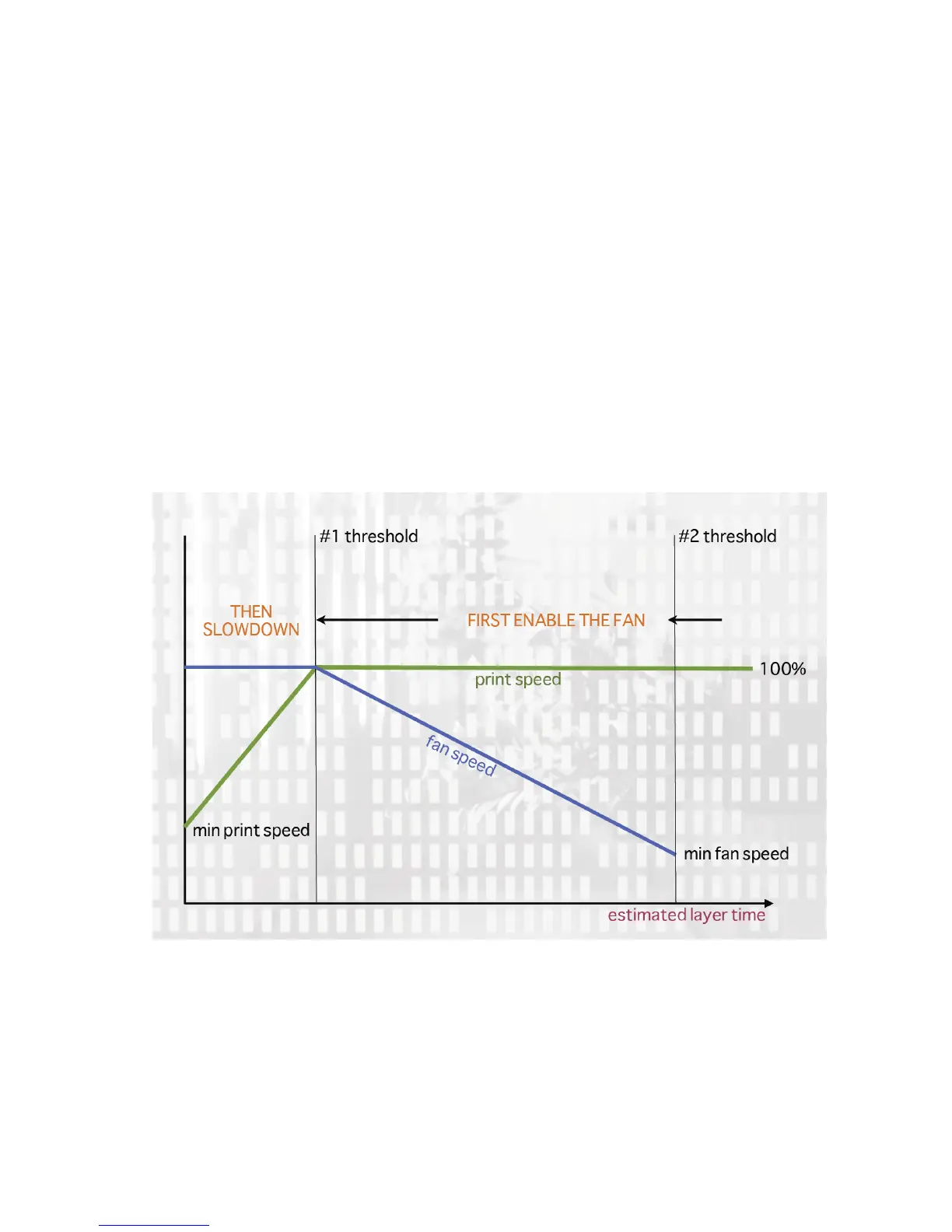

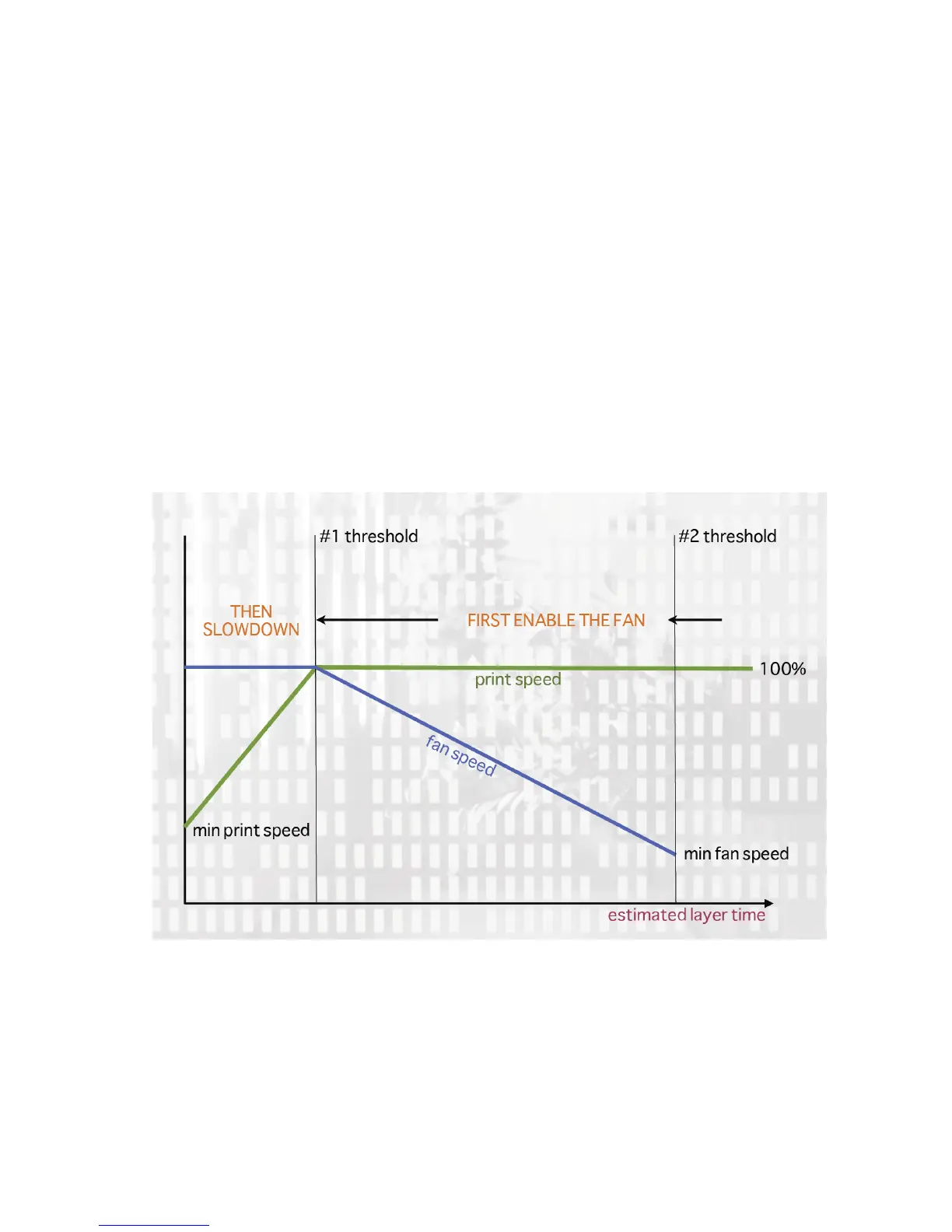

There are two main techniques for cooling: adding a fan and slowing

down the print speed. Slic3r may choose to use both techniques, using a

fan first, and then slowing down the print if the layer time is too fast.

Figure 3.34: Cooling strategy.

Figure 3.34 shows the strategy adopted by Slic3r. Reading from right

to left, when the minimum fan threshold (#2) is reached the fan is turned

77

Loading...

Loading...