Slic3r in Depth

• Only retract when crossing perimeters

- Retracting, to prevent

ooze, is unnecessary if the extruder remains within the boundaries of

the model. Care should be taken if the print material oozes excessively,

as not retracting may result in enough material loss to affect the

quality of the subsequent extrusion. However, most modern printers

and materials rarely suffer from such extreme ooze problems.

• Infill before perimeters

- Reverses the order in which the layer

is printed. Usually the perimeter is laid down initially, followed by

the infill, and this is usually the preferable as the perimeter acts as a

wall containing the infill.

Fighting Ooze

Unless the material being extruded has a very high viscosity it will ooze

from the nozzle in between extrusions. There are several settings in Slic3r

to which can help to remedy this.

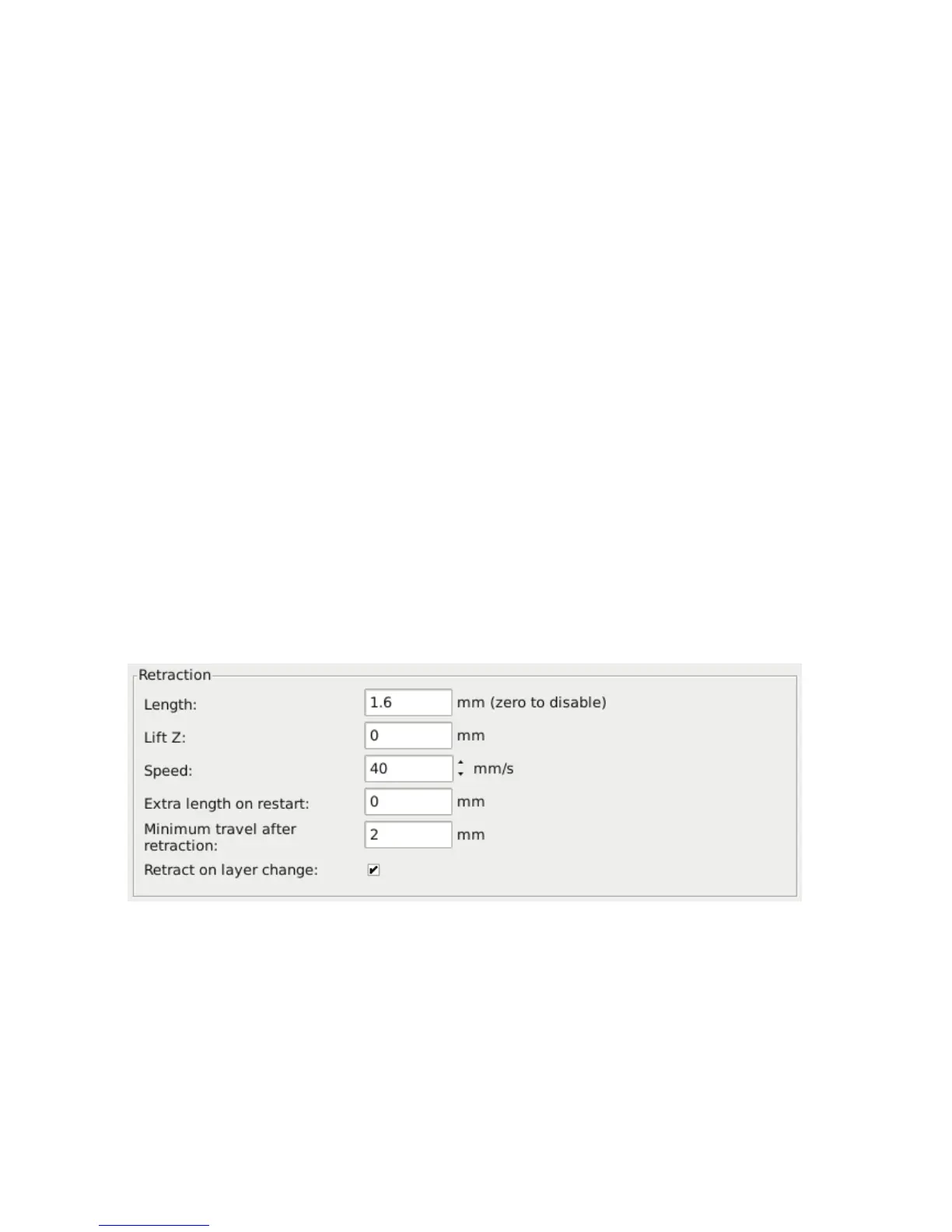

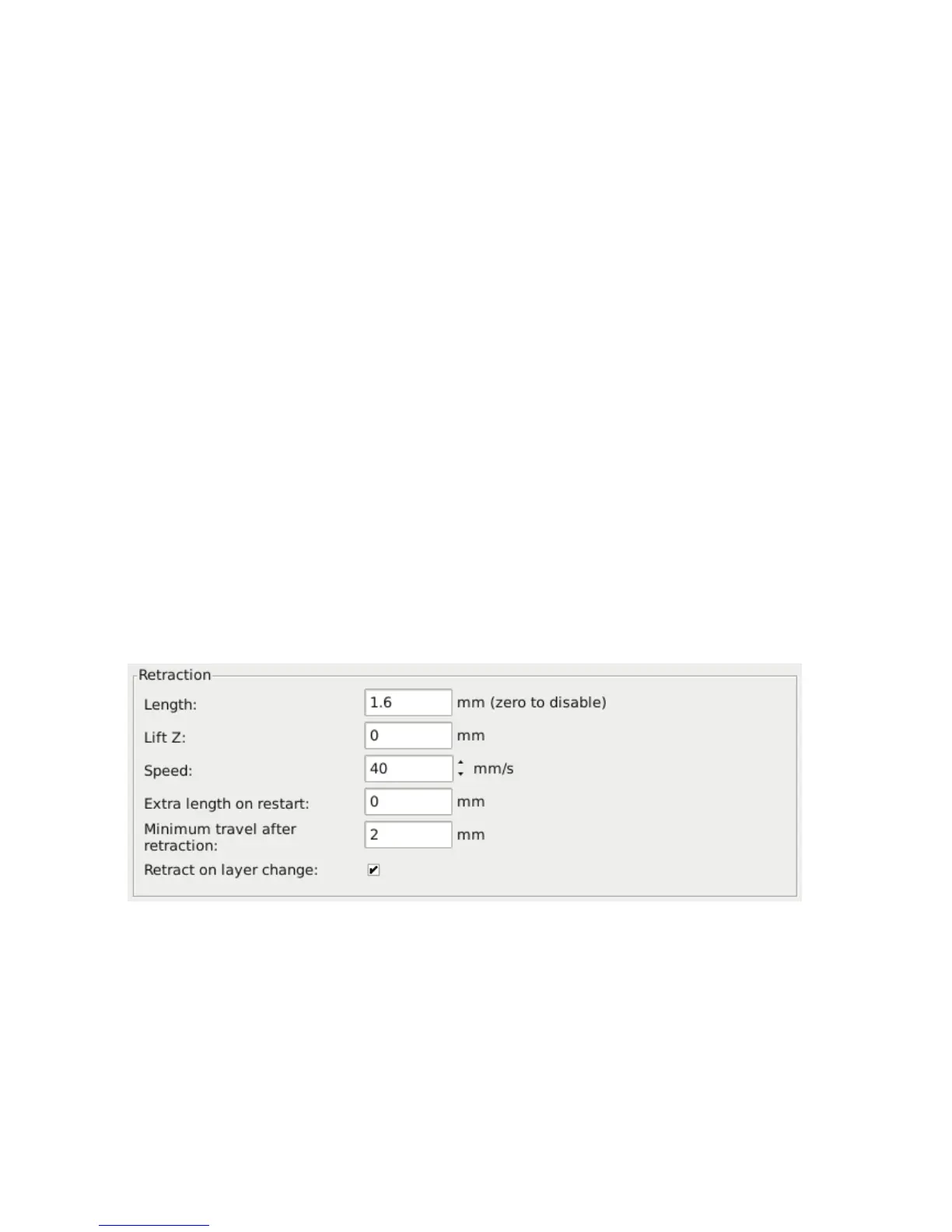

The retraction settings, found in the

Printer

tab, tell the printer to pull

back the filament between extrusion moves. This can alleviate the pressure

in the nozzle, thus reducing ooze. After the subsequent travel move the

retraction is reversed to prepare the extruder for the next extrusion.

Figure 3.32: Retraction settings.

• Length

- The number of millimeters to retract. Note that the

measurement is taken from the raw filament entering the extruder.

A value of between 1 and 2mm is usually recommended. Bowden

74

Loading...

Loading...